Gatlin Gun ...........................................

Nice gun but this is not what I had in mind.

Click on image for larger view |

How about the GAV-8 Avenger from Wikipedia

| The General Electric GAU-8/A Avenger is a 30 mm hydraulically-driven

seven-barrel Gatling-type cannon that is mounted on the United States Air

Force's Fairchild Republic A-10 Thunderbolt II. It is among the largest,

heaviest and most powerful aircraft cannons in the United States military.

Designed specifically for the anti-tank role, the Avenger delivers very

powerful rounds at a high rate of fire.

History

The GAU-8 was created as a parallel program with the A-X

(or Attack Experimental) competition that produced the A-10. The specification

for the cannon was laid out in 1970, with General Electric and Philco-Ford

offering competing designs. Both of the A-X prototypes, the YA-10 and the

Northrop YA-9, were designed to incorporate the weapon, although it was

not available during the initial competition, and the M61 Vulcan was used

as a temporary replacement. Once completed, the entire GAU-8 assembly (correctly

referred to as the A/A 49E-6 Gun System) represents about 16% of the A-10

aircraft's unladen weight. |

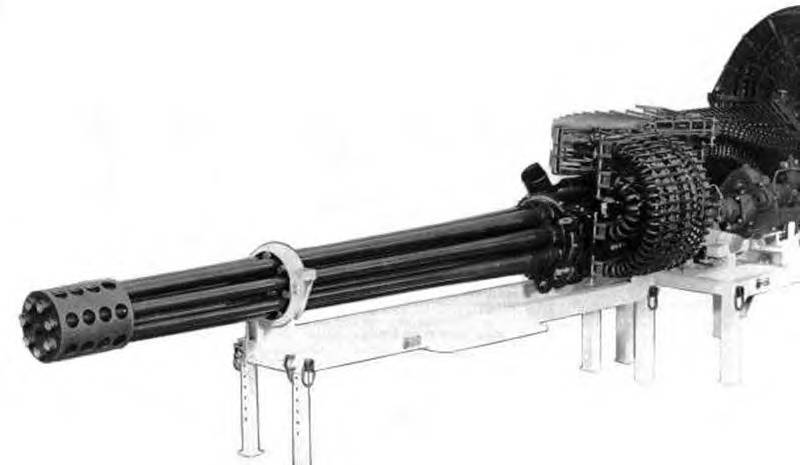

The GAU-8/A Avenger's barrel and breech assembly

(ammunition drum off edge of photo).

Click on image for larger view |

GAU-8 closeup

Click on image for larger view |

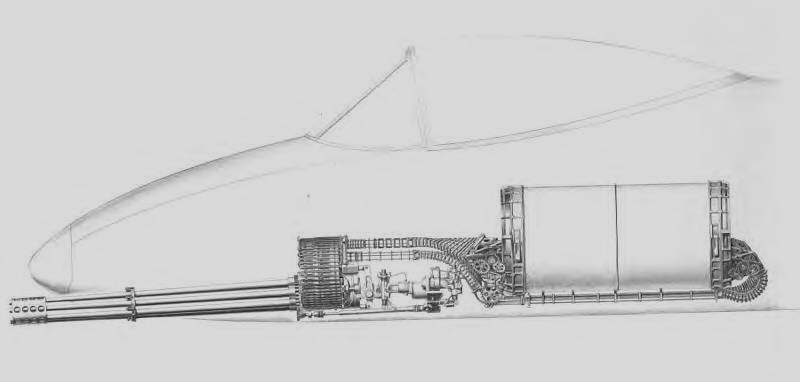

The gun is placed slightly off center in the nose of

the plane with the front landing gear positioned to the right of the center

line, so that the actively firing cannon barrel is directly on the aircraft's

center line. The Russian Gryazev-Shipunov GSh-6-30 is a similar class of

weapon, although it is lighter with a higher fire rate, but has a lower

muzzle velocity and overheats faster.

The A-10 and its GAU-8/A gun entered service in 1977.

It was produced by General Electric, though General Dynamics Armament and

Technical Products has been responsible for production and support since

1997 when the division was sold by Lockheed Martin to General Dynamics.

The gun is loaded using Syn-Tech's linked tube carrier

GFU-8/E 30 mm Ammunition Loading Assembly cart. This vehicle is unique

to the A-10 and the GAU-8. |

Design

The GAU-8 itself weighs 620 pounds (280 kg), but the complete

weapon, with feed system and drum, weighs 4,029 pounds (1,828 kg) with

a maximum ammunition load. It measures 19 ft 5 1?2 in (5.931 m) from the

muzzle to the rearmost point of the ammunition system, and the ammunition

drum alone is 34.5 inches (88 cm) in diameter and 71.5 inches (1.82 m)

long. Power for operating the gun is provided by twin 77 hp electric motors.

The magazine can hold 1,174 rounds, although 1,150 is the typical load-out.

Muzzle velocity when firing Armor-Piercing Incendiary rounds is 3,250 feet

per second (990 m/s), almost the same as the substantially lighter M61

Vulcan's 20 mm round.

The standard ammunition mixture for anti-armor use is

a four-to-one mix of PGU-14/B Armor Piercing Incendiary, with a projectile

weight of about 15.0 oz (425 grams or 6,560 grains) and PGU-13/B High Explosive

Incendiary (HEI) rounds, with a projectile weight of about 12.7 oz (360

grams or 5,556.25 grains)[citation needed]. The PGU-14/B's projectile incorporates

a lightweight aluminum body, cast around a smaller caliber depleted uranium

penetrating core. The Avenger is lethal against tanks and all other armored

vehicles.

| A very important innovation in the design of the GAU-8/A

shells is the use of aluminum alloy cases in place of the traditional steel

or brass. This alone adds 30% to ammunition capacity for a given weight.

The shells also have plastic driving bands to improve barrel life. They

are imposing to examine and handle, measuring 11.4 inches (290 mm) in length

and weighing 1.53 pounds (0.69 kg) or more.

The Avenger's rate of fire was originally selectable,

2,100 rounds per minute (rpm) in the low setting, or 4,200 rpm in the high

setting. Later this was changed to a fixed rate of 3,900 rpm. In practice,

the cannon is limited to one and two-second bursts to avoid overheating

and conserve ammunition; barrel life is also a factor, since the USAF has

specified a minimum life of at least 20,000 rounds for each set of barrels.

There is no technical limitation on the duration the gun may be continuously

fired, and a pilot could potentially expend the entire ammunition load

in a single burst with no damage or ill effects to the weapons system itself.

However, this constant rate of fire would shorten the barrel life considerably

and require added barrel inspections and result in shorter intervals between

replacement.

Each barrel is a very simple non-automatic design having

its own breech and bolt. Like the original Gatling gun, the entire firing

cycle is actuated by cams and powered by the rotation of the barrels. The

barrels themselves are driven by the aircraft's dual hydraulic system.

|

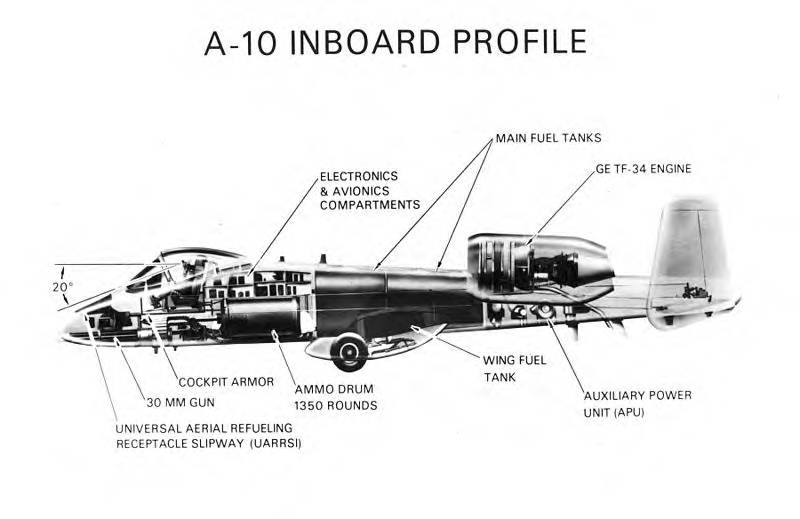

GAU-8 mounted in A-10

Click on image for larger view |

The GAU-8/A ammunition is linkless, reducing weight and avoiding

a great deal of potential for jamming. The feed system is double-ended,

allowing the spent casings to be recycled back into the ammunition drum,

instead of ejected from the aircraft, which would require considerable

force to eliminate potential airframe damage. The feed system is based

on that developed for later M61 installations, but uses more advanced design

techniques and materials throughout, to save weight.

Firing system

Accuracy

The GAU-8/A is extremely accurate and can fire 4200 rounds

per minute without complications. The 30-mm shell has twice the range,

half the time to target, and three times the mass of projectiles carried

by comparable Close Air Support aircraft.

| The muzzle velocity of the GAU-8/A is about the same

as that of the M61 Vulcan cannon, but uses heavier ammunition and has superior

ballistics. Its time of flight to 4,000 feet (1,200 m) is 30 percent less

than that of an M61 round, the projectile decelerates much less rapidly

after leaving the barrel, and it drops a negligible amount, about 10 feet

(3.0 m) over the distance. The GAU-8/A accuracy when installed in the A-10

is rated at "5 mil, 80 percent", meaning that 80 percent of rounds fired

at 4,000 feet (1,200 m) will hit the target within a 40 feet (12 m) diameter

circle. By comparison, the M61 has an 8-milliradian dispersion.

Recoil

Each barrel fires when it reaches roughly the 9 o'clock

position, when viewed from the front of the plane. Because the gun's recoil

forces could push the entire plane off target during firing, the weapon

itself is mounted off-center in the other direction, toward the 3 o'clock

position, so that the firing barrel lies directly on the aircraft's |

Longer than a standard VW

Click on image for larger view |

center line. The firing barrel also lies just below the aircraft's

center of gravity, being bore sighted along a line 2 degrees below the

aircraft's line of flight. This arrangement accurately centers the recoil

forces, preventing changes in pitch and/or yaw when fired. This configuration

also provides space for the front landing gear, which are mounted slightly

off-center on the right side of the nose.

The GAU-8/A utilizes recoil adapters. They are the interface

between the gun housing and the gun mount. By absorbing (in compression)

the recoil forces, they spread the time of the recoil impulse and counter

recoil energy transmitted to the supporting structure when the gun is fired.

The A-10 engines were initially susceptible to flameout

when subjected to gases generated in the firing of the gun. When the GAU-8

is being fired, the smoke from the gun can make the engines stop, and this

did occur during initial flight testing. Gun exhaust is essentially oxygen-free,

and is certainly capable of causing flame-outs of gas turbines. The A-10

engines now have a self sustaining combustion section. When the gun is

fired the igniters come on to reduce the possibility of a flame-out.

The recoil force of the GAU-8/A is 10,000 pounds-force

(45 kN), which is slightly more than the output of one of the A-10's two

TF34 engines (9,065 lbf / 40.3 kN each). While this recoil force is significant,

in practice cannon fire only slows the aircraft a few miles per hour.

Variants

Some of the GAU-8/A technology has been transferred into

the smaller 25 mm GAU-12/U Equalizer developed for the AV-8B Harrier II

aircraft, which is about the same size as the M61, but is considerably

more lethal. GE has also developed the GAU-13/A, a four-barreled weapon

using GAU-8/A components, which has been tested in podded form as the GPU-5/A,

and the Avenger forms the basis for the Dutch-developed Goalkeeper CIWS

naval air-defence gun. No current or contemplated aircraft other than the

A-10, however, carries the full-up Avenger system.

A side-view drawing of the GAU-8/A Avenger's mounting

location in the A-10's forward fuselage |

.

Type Gatling-type autocannon

Place of origin United States

Service history

In service 1977–present

Used by United States Air Force (Avenger)

Various navies (Goalkeeper)

Production history

Manufacturer General Electric

Number built Approx. 715

Variants GAU-12/U Equalizer

GAU-13/A

Specifications

Weight 619.5 lb (281 kg)

Length 19 ft 10.5 in (6.06 m) (total system)

112.28 in (2.85 m) (barrel only)

Barrel length 90.5 in (2.30 m)

Width 17.2 in (0.437 m) (barrel only)

Cartridge 30 × 173 mm

Caliber 30 mm caliber

Barrels 7-barrel (progressive RH parabolic

twist, 14 grooves)

Action Electric-Motor, Hydraulic-Driven

Rate of fire up to 4,200 rpm (rounds per

minute)

Muzzle velocity 3,500 ft/s (1,070 m/s)

Effective range 4,000 feet (1,220 m)

Maximum range Over 12,000 feet (3,660 m)

Feed system Linkless feed system |

. |

| The airplane we put this gatlin gun in.

Fairchild Republic A-10 Thunderbolt II from Wikipedia

The Fairchild Republic A-10 Thunderbolt II is an American

single-seat, twin-engine, straight-wing jet aircraft developed by Fairchild-Republic

in the early 1970s. The A-10 was designed for a United States Air Force

requirement to provide close air support (CAS) for ground forces by attacking

tanks, armored vehicles, and other ground targets with a limited air interdiction

capability. It is the first U.S. Air Force aircraft designed solely for

close air support.

The A-10 was designed around the GAU-8 Avenger, a heavy

rotary cannon which forms the aircraft's primary armament (and is, to date,

the heaviest rotary cannon ever mounted on an aircraft). The aircraft's

hull incorporates over 1,200 pounds (540 kg) of armor and was designed

with survivability as a priority, with protective measures in place which

enable the aircraft to continue flying even after taking significant damage.

The A-10's official name comes from the Republic P-47

Thunderbolt of World War II, a fighter that was particularly effective

at close air support. The A-10 is more commonly known by its nickname "Warthog"

or simply "Hog". As a secondary mission, it provides airborne forward air

control, guiding other aircraft against ground targets. A-10s used primarily

in this role are designated OA-10. The A-10 is not expected to be replaced

until 2028 or later.

Development

Background

Criticism that the U.S. Air Force did not take close air

support seriously prompted a few service members to seek a specialized

attack aircraft. In the Vietnam War, large numbers of ground-attack aircraft

were shot down by small arms, surface-to-air missiles, and low-level anti-aircraft

gunfire, prompting the development of an aircraft better able to survive

such weapons. In addition, the UH-1 Iroquois and AH-1 Cobra helicopters

of the day, which USAF commanders had said should handle close air support,

were ill-suited for use against armor, carrying only anti-personnel machine

guns and unguided rockets meant for soft targets. Fast jets such as the

F-100 Super Sabre, F-105 Thunderchief and F-4 Phantom II proved for the

most part to be ineffective for close air support, because their high speed

did not allow pilots enough time to get an accurate fix on ground targets

and they lacked sufficient loiter time. The effective, but aging A-1 Skyraider

was the USAF's primary close air support aircraft.

A-X program

In 1966 the U.S. Air Force formed the Attack Experimental

(A-X) program office. On 6 March 1967, the Air Force released a request

for information to 21 defense contractors for the A-X. The objective was

to create a design study for a low-cost attack aircraft. The officer in

charge of the project was Colonel Avery Kay. In 1969, the Secretary of

the Air Force asked Pierre Sprey to write the detailed specifications for

the proposed A-X project. However, his initial involvement was kept secret

because of Sprey's earlier controversial involvement in the F-X project.

Sprey's discussions with A-1 Skyraider pilots operating

in Vietnam and analysis of the effectiveness of current aircraft used in

the role indicated the ideal aircraft should have long loiter time, low-speed

maneuverability, massive cannon firepower, and extreme survivability; an

aircraft that had the best elements of the Ilyushin Il-2, Henschel Hs 129

and Skyraider. The specifications also demanded that each aircraft cost

less than $3 million. Sprey required that the biography of World War II

attack pilot Hans-Ulrich Rudel be read by people on A-X program.

In May 1970, the USAF issued a modified and much more

detailed request for proposals (RFP) for the aircraft. The threat of Soviet

armored forces and all-weather attack operations had become more serious.

Now included in the requirements was that the aircraft would be designed

specifically for the 30 mm cannon. The RFP also specified an aircraft with

a maximum speed of 460 mph (400 kn; 740 km/h), takeoff distance of 4,000

feet (1,200 m), external load of 16,000 pounds (7,300 kg), 285-mile (460

km) mission radius, and a unit cost of US$1.4 million. The A-X would be

the first Air Force aircraft designed exclusively for close air support.

During this time, a separate RFP was released for A-X's

30 mm cannon with requirements for a high rate of fire (4,000 round/minute)

and a high muzzle velocity. Six companies submitted aircraft proposals

to the USAF, with Northrop and Fairchild Republic selected to build prototypes:

the YA-9A and YA-10A, respectively. General Electric and Philco-Ford were

selected to build and test GAU-8 cannon prototypes.

The YA-10A was built in Hagerstown, Maryland and first

flew on 10 May 1972. After trials and a fly-off against the YA-9A, the

Air Force announced its selection of Fairchild-Republic's YA-10A on 18

January 1973 for production. General Electric was selected to build the

GAU-8 cannon in June 1973. The YA-10 had an additional fly-off in 1974

against the Ling-Temco-Vought A-7D Corsair II, the principal Air Force

attack aircraft at the time, in order to prove the need to purchase a new

attack aircraft. The first production A-10 flew in October 1975, and deliveries

to the Air Force commenced in March 1976. In total, 715 airplanes were

produced, the last delivered in 1984.

One experimental two-seat A-10 Night Adverse Weather (N/AW)

version was built by converting an A-10A. The N/AW was developed by Fairchild

from the first Demonstration Testing and Evaluation (DT&E) A-10 for

consideration by the USAF. It included a second seat for a weapons system

officer responsible for electronic countermeasures (ECM), navigation and

target acquisition. The variant was canceled, and the only two-seat A-10

built now resides at Edwards Air Force Base's Flight Test Center Museum.

The N/AW version did not interest the USAF or export customers. The two-seat

trainer version was ordered by the Air Force in 1981, but funding was canceled

by U.S. Congress and the jet was not produced.

Upgrades

The A-10 has received many upgrades over the years. Aircraft

added the Pave Penny laser receiver pod beginning in 1978. It senses reflected

laser radiation from a laser designator on a target for faster and more

accurate target identification. The A-10 began receiving an inertial navigation

system in 1980. Later, the Low-Altitude Safety and Targeting Enhancement

(LASTE) upgrade provided computerized weapon-aiming equipment, an autopilot,

and a ground-collision warning system. The A-10 is now compatible with

night vision goggles for low-light operation. In 1999, aircraft began to

receive Global Positioning System navigation systems and a new multi-function

display. Its LASTE system is being upgraded with the Integrated Flight

& Fire Control Computers (IFFCC).

In 2005, the entire A-10 fleet also began receiving the

Precision Engagement upgrades that include an improved fire control system

(FCS), electronic countermeasures (ECM), and the ability to aim smart bombs.

The aircraft that receive this upgrade are redesignated A-10C. The A-10

will receive a service life extension program (SLEP) upgrade with many

receiving new wings. A contract to build 242 new A-10 wing sets was awarded

to Boeing in June 2007. In July 2010, the USAF issued Raytheon a contract

to integrate a Helmet Mounted Integrated Targeting (HMIT) system into A-10Cs.

Two A-10s flew in November 2011 with the new wing installed. The service

life of the re-winged aircraft is extended to 2040.

The Government Accounting Office in 2007 estimated the

cost of upgrading, refurbishing, and service life extension plans for the

A-10 force to total $2.25 billion through 2013. Modifications to provide

precision weapons capability are well underway. The Air Force Material

Command's Ogden Air Logistics Center at Hill AFB, Utah completed work on

its 100th A-10 precision engagement upgrade in January 2008. The C model

upgrades are to be completed in 2011

| Design

Overview

The A-10 has superior maneuverability at low speeds and

altitude because of its large wing area, high wing aspect ratio, and large

ailerons. The high aspect ratio wing also allows for short takeoffs and

landings, permitting operations from primitive forward airfields near front

lines. The aircraft can loiter for extended periods and operate under 1,000

ft (300 m) ceilings with 1.5 mi (2.4 km) visibility. It typically flies

at a relatively slow speed of 300 knots (350 mph; 560 km/h), which makes

it a much better platform for the ground-attack role than fast fighter-bombers,

which often have difficulty targeting small and slow-moving targets.

Engine exhaust passes over the aircraft's horizontal stabilizer

and between the twin tails, decreasing the A-10's infrared signature and

lowering the likelihood that the aircraft can be targeted by heat-seeking

missiles fired from the ground. The placement |

A-10 inboard profile drawing

Click on image for larger view |

of the engines behind the wings partially shields them from

anti-aircraft fire. The leading edge of the wing is honeycomb panel construction

to provide strength with minimal weight compromise. Honeycomb panels of

this type on the A-10 include the flap shrouds, elevators, rudders and

other sections of the fins.

An A-10A of pre-glass cockpit design

Click on image for larger view |

The A-10 has integrally machined skin panels. Because

the stringers are integral with the skin there are no joint or seal problems.

These panels, fabricated using computer controlled machining, reduce the

time and hence the cost of production. Combat experience has shown that

this type of panel is more resistant to damage. The skin is not load-bearing,

so damaged skin sections can be easily replaced in the field, with makeshift

materials if necessary.

The ailerons are at the far ends of the wings to gain

greater rolling moment, as with many aircraft, but there are two distinguishing

features. The ailerons are larger than is typical, almost 50% of the wingspan,

providing improved control even at slow speeds. The aileron is also split,

making it a deceleron.

The A-10 is designed to be refueled, rearmed, and serviced

with minimal equipment. Also, most repairs can be done in the field. An

unusual feature is that many of the aircraft's parts are interchangeable

between the left and right sides, including the engines, main landing gear,

and vertical stabilizers. The sturdy landing gear, low-pressure tires and

large, straight wings allow operation from short |

rough strips even with a heavy ordnance load, allowing the

aircraft to operate from damaged airbases. If runways are damaged in an

attack, the A-10 can operate from taxiways or straight roadway sections.

| The front landing gear is offset to the aircraft's right

to allow placement of the 30 mm cannon with its firing barrel along the

centerline of the aircraft. During ground taxi, the offset front landing

gear causes the A-10 to have dissimilar turning radii. Turning to the right

on the ground takes less distance than turning left.

Durability

The A-10 is exceptionally tough. Its strong airframe can

survive direct hits from armor-piercing and high-explosive projectiles

up to 23 mm. The aircraft has triple redundancy in its flight systems,

with mechanical systems to back up double-redundant hydraulic systems.

This permits pilots to fly and land when hydraulic power or part of a wing

is lost. Flight without hydraulic power uses the manual reversion flight

control system; this engages automatically for pitch and yaw control, and

under pilot control (manual reversion switch) for roll control. In manual

reversion mode, the A-10 is sufficiently controllable under favorable conditions

to return to base and land, though control forces are much higher than

normal. The aircraft is designed to fly with one engine, one tail, one

elevator, and half of one wing missing.

Its self-sealing fuel tanks are protected by fire-retardant

foam. The A-10's main |

Front view of an A-10 showing the 30 mm

cannon and offset front landing gear

Click on image for larger view |

landing gear is designed so that the wheels semi-protrude

from their nacelles when the gear is retracted so as to make gear-up belly

landings easier to control and less damaging to the aircraft's underside.

Additionally, the landing gear are all hinged toward the rear of the aircraft,

so if hydraulic power is lost the pilot can drop the gear and a combination

of gravity and wind resistance will open and lock the gear in place.

The cockpit and parts of the flight-control system are

protected by 1,200 lb (540 kg) of titanium armor, referred to as a "bathtub".

The armor has been tested to withstand strikes from 23 mm cannon fire and

some strikes from 57 mm rounds. It is made up of titanium plates with thicknesses

from 0.5 to 1.5 inches (13 to 38 mm) determined by a study of likely trajectories

and deflection angles. This protection comes at a cost, with the armor

making up almost 6% of the aircraft's empty weight. To protect the pilot

from the fragmentation likely to be created from impact of a shell, any

interior surface of the tub that is directly exposed to the pilot is covered

by a multi-layer nylon spall shield. In addition, the front windscreen

and canopy are resistant to small arms fire

This A-10 Thunderbolt II suffered extensive damage

over Baghdad during Operation Iraqi Freedom

in early 2003. It successfully returned to base.

Click on image for larger view |

Proof of the durability of the A-10 was shown when Captain

Kim Campbell, flying a ground support mission over Baghdad during the 2003

invasion of Iraq on 7 April, suffered extensive flak damage to her A-10.

Iraqi fire damaged one of the A-10's engines and crippled its hydraulic

system, which required the aircraft's stabilizer and flight controls to

be operated via the back-up mechanical system, this being known as 'manual

reversion mode'. Despite this damage, Campbell managed to fly the aircraft

for nearly an hour and landed safely.

There are several reasons for the unusual location of

the A-10's General Electric TF34-GE-100 turbofan engines. First, the A-10

was envisioned to fly from forward air bases, often with substandard, semi-prepared

runways that present a high risk of foreign object damage to the engines.

The height of the engines decreases the chance that sand or stones will

be ingested. This also allows engines to keep running while the aircraft

is serviced and rearmed by ground crews, reducing turn-around time. Without

the limitations imposed by engines, the wings could be mounted closer to

the ground, to simplify servicing and rearming.

The engines' high 6:1 bypass ratio provides the A-10 with

a relatively small infrared signature, and their position directs exhaust

over the tailplanes further shielding it |

from detection by heat-seeking surface to air missiles. The

engines are angled upward by nine degrees to cancel out the nose-down pitching

moment they would otherwise generate due to being mounted above the aerodynamic

center of the aircraft. This avoids the necessity to trim the control surfaces

against the force. The heavy engines require strong supports, so their

pylons are connected to the airframe by four bolts.

The A-10's fuel system components are protected in multiple

ways. All four fuel tanks are located near the center of the aircraft,

reducing the likelihood that they will be hit or have their fuel lines

severed. The tanks are separate from the fuselage; thus, projectiles would

need to penetrate the aircraft's skin before reaching the outer skin of

the tank. The refueling system is purged after use so that all fuel in

the aircraft is protected from fire. All fuel transfer lines self-seal

if they are compromised; if a tank is damaged beyond its ability to self-seal,

check valves prevent fuel flowing into the compromised tank. Most of the

fuel system components are inside the tanks so that fuel will not be lost

in case a component were to leak. Most importantly, reticulated polyurethane

foam lines both the inner and outer sides of the fuel tanks, retaining

debris and restricting fuel spillage in the event of damage. The other

source of possible combustion, the engines, are shielded from the fuel

system and the rest of the airframe by firewalls and fire extinguishing

equipment. Even in the event of all four main tanks being penetrated and

all contents lost, sufficient fuel is carried in two self-sealing sump

tanks to allow flight for 230 miles (370 km).

Weapon systems

Although the A-10 can carry considerable disposable stores,

its primary built-in weapon is the 30 mm GAU-8/A Avenger Gatling-type cannon.

One of the most powerful aircraft cannons ever flown, it fires large depleted

uranium armor-piercing shells. In the original design, the pilot could

switch between two rates of fire: 2,100 or 4,200 rounds per minute; this

was changed to a fixed rate of 3,900 rounds per minute. The cannon takes

about half a second to come up to speed, so 50 rounds are fired during

the first second, 65 or 70 rounds per second thereafter. The gun is accurate

enough to place 80% of its shots within a 40-foot (12.4 m) diameter circle

from 4,000 feet (1,220 m) while in flight. The GAU-8 is optimized for a

slant range of 4,000 feet (1,220 m) with the A-10 in a 30 degree dive.

The fuselage of the aircraft is built around the gun.

The gun's firing barrel is placed at the 9 o'clock position so it is aligned

on the aircraft's centerline. The gun's ammunition drum can hold up to

1,350 rounds of 30 mm ammunition, but generally holds 1,174 rounds. The

damage caused by rounds firing prematurely from impact of an explosive

shell would be catastrophic, so a great deal of effort has been taken to

protect the 5 feet 11.5 inch (1.816 m) long drum. There are many armor

plates of differing thicknesses between the aircraft skin and the drum,

to detonate an incoming shell before it reaches the drum. A final layer

of armor around the drum protects it from fragmentation damage. The gun

is loaded by Syn-Tech's linked tube carrier GFU-7/E 30 mm ammunition loading

assembly cart.

Another commonly used weapon is the AGM-65 Maverick air-to-surface

missile, with different variations for either electro-optical (TV-guided)

or infrared targeting. The Maverick allows targets to be engaged at much

greater ranges than the cannon, a safer proposition in the face of modern

anti-aircraft systems. During Desert Storm, in the absence of dedicated

forward-looking infrared (FLIR) cameras for night vision, the Maverick's

infrared camera was used for night missions as a "poor man's FLIR". Other

weapons include cluster bombs and Hydra rocket pods. Although the A-10

is equipped to carry laser-guided bombs, their use is relatively uncommon.

The A-10 has not been equipped with weapon control systems for accurate

bombing as of 2000. A-10s usually fly with an ALQ-131 ECM pod under one

wing and two AIM-9 Sidewinder air-to-air missiles under the other wing

for self-defense.

| Modernization

The A-10 Precision Engagement Modification Program will

update 356 A-10/OA-10s to the A-10C variant with a new flight computer,

new glass cockpit displays and controls, two new 5.5-inch (140 mm) color

displays with moving map function and an integrated digital stores management

system.

Other funded improvements to the A-10 fleet include a

new data link, the ability to employ smart weapons such as the Joint Direct

Attack Munition ("JDAM") and Wind Corrected Munitions Dispenser, and the

ability to carry an integrated targeting pod such as the Northrop Grumman

LITENING targeting pod or the Lockheed Martin Sniper XR Advanced Targeting

Pod (ATP). Also included is the Remotely Operated Video Enhanced Receiver

(ROVER) to provide sensor data to personnel on the ground. |

A-10 Thunderbolt II, fully armed

Click on image for larger view |

Colors and markings

Since the A-10 flies low to the ground and at subsonic

speed, aircraft camouflage is important to make the aircraft more difficult

to see. Many different types of paint schemes have been tried. These have

included a "peanut scheme" of sand, yellow and field drab; black and white

colors for winter operations and a tan, green and brown mixed pattern.

The two most common markings applied to the A-10 have

been the European I woodland camouflage scheme and a two-tone gray scheme.

The European woodland scheme was designed to minimize visibility from above,

as the threat from hostile fighter aircraft was felt to outweigh that from

ground-fire. It uses dark green, medium green and dark gray in order to

blend in with the typical European forest terrain and was used from the

1980s to the early 1990s. Following the end of the Cold War, and based

on experience during the 1991 Gulf War, the air-to-air threat was no longer

seen to be as important as that from ground fire, and a new color scheme

known as "Compass Ghost" was chosen to minimize visibility from below.

This two-tone gray scheme has darker gray color on top, with the lighter

gray on the underside of the aircraft, and started to be applied from the

early 1990s.

Many A-10s also featured a false canopy painted in dark

gray on the underside of the aircraft, just behind the gun. This form of

automimicry is an attempt to confuse the enemy as to aircraft attitude

and maneuver direction.

| Operational history

Introduction

The first unit to receive the A-10 Thunderbolt II was

the 355th Tactical Training Wing, based at Davis-Monthan Air Force Base,

Arizona, in March 1976. The first unit to achieve full combat-readiness

was the 354th Tactical Fighter Wing at Myrtle Beach AFB, South Carolina,

in 1978. Deployments of A-10As followed at bases both at home and abroad,

including England AFB, Louisiana; Eielson AFB, Alaska; Osan Air Base, South

Korea; and RAF Bentwaters/RAF Woodbridge, England. The 81st TFW of RAF

Bentwaters/RAF Woodbridge operated rotating detachments of A-10s at four

bases in Germany known as Forward Operating Locations (FOLs): Leipheim,

Sembach Air Base, Nörvenich, and Ahlhorn.

A-10s were initially an unwelcome addition to many in

the Air Force. Most pilots switching to the A-10 did not want to because

fighter pilots traditionally favored speed and appearance. In 1987, many

A-10s were shifted to the forward air control (FAC) role and redesignated

OA-10. In the FAC role the OA-10 is typically |

A-10 Thunderbolt II firing off an AGM-65

on one of the Eglin AFB weapons ranges.

Click on image for larger view |

equipped with up to six pods of 2.75 inch (70 mm) Hydra rockets,

usually with smoke or white phosphorus warheads used for target marking.

OA-10s are physically unchanged and remain fully combat capable despite

the redesignation.

Gulf War and Balkans

The A-10 was used in combat for the first time during

the Gulf War in 1991, destroying more than 900 Iraqi tanks, 2,000 military

vehicles, and 1,200 artillery pieces. A-10s shot down two Iraqi helicopters

with the GAU-8 cannon. The first of these was an Iraqi helicopter shot

down by Captain Robert Swain over Kuwait on 6 February 1991, marking the

A-10's first air-to-air victory. Four A-10s were shot down during the war,

all by surface-to-air missiles. Another three battle-damaged A-10s and

OA-10As returned to base but were written off, some sustaining additional

damage in crashed landings. The A-10 had a mission capable rate of 95.7%,

flew 8,100 sorties, and launched 90% of the AGM-65 Maverick missiles fired

in the conflict. Shortly after the Gulf War, the Air Force gave up on the

idea of replacing the A-10 with a close air support version of the F-16.

U.S. Air Force A-10 Thunderbolt II aircraft fired approximately

10,000 30 mm rounds in Bosnia and Herzegovina in 1994–95. Following the

seizure of some heavy weapons by Bosnian Serbs from a warehouse in Ilidža,

a series of sorties were launched to locate and destroy the captured equipment.

On 5 August 1994, two A-10s located and strafed an anti-tank vehicle. Afterwards,

the Serbs agreed to return remaining heavy weapons. In August 1995, NATO

launched an offensive called Operation Deliberate Force. A-10s flew close

air support missions, attacking Serbian artillery and positions. In late

September A-10s began flying patrols again.

A-10s returned to the region as part of Operation Allied

Force in Kosovo beginning in March 1999. In March 1999, A-10s escorted

and supported search and rescue helicopters in finding a downed F-117 pilot.

The A-10s were deployed to support search and rescue missions. But the

Warthogs began to receive more ground attack missions as the days passed.

The A-10's first successful attack in Operation Allied Force happened on

6 April 1999. A-10s remained until combat ended in late June 1999.

Afghanistan, Iraq and Libya Wars

During the 2001 invasion of Afghanistan, A-10s did not

take part in the initial stages. For the campaign against Taliban and Al

Qaeda, A-10 squadrons were deployed to Pakistan and Bagram Air Base, Afghanistan,

beginning in March 2002. These A-10s participated in Operation Anaconda.

Afterwards, A-10s remained in-country, fighting Taliban and Al Qaeda remnants.

Operation Iraqi Freedom began on 20 March 2003. Sixty

OA-10/A-10 aircraft took part in early combat there. United States Air

Forces Central issued Operation Iraqi Freedom: By the Numbers, a declassified

report about the aerial campaign in the conflict on 30 April 2003. During

that initial invasion of Iraq, A-10s had a mission capable rate of 85%

in the war and fired 311,597 rounds of 30 mm ammunition. A single A-10

was shot down near Baghdad International Airport by Iraqi fire late in

the campaign. The A-10 also flew 32 missions in which the aircraft dropped

propaganda leaflets over Iraq.

The A-10C first deployed to Iraq in the third quarter

of 2007 with the 104th Fighter Squadron of the Maryland Air National Guard.

The jets include the Precision Engagement Upgrade. The A-10C's digital

avionics and communications systems have greatly reduced the time to acquire

a close air support target and attack it.

On 25 March 2010, an A-10 conducted the first flight of

an aircraft with all engines powered by a biofuel blend. The flight, performed

at Eglin Air Force Base, used a 1:1 blend of JP-8 and Camelina-based fuel.

In March 2011, six A-10s were deployed as part of Operation

Odyssey Dawn, the coalition intervention in Libya. They participated in

attacks on Libyan ground forces there.

Future retirement

The A-10 is scheduled to be in service with the USAF until

2028 and possibly later, when it may be replaced by the Lockheed Martin

F-35 Lightning II. Critics have responded by saying that replacing the

A-10 with the F-35 would be a "giant leap backwards" given the performance

of the Warthog and the rising costs of the F-35 program. In 2012, the Air

Force concluded the F-35B cannot generate enough sorties to meet their

needs, and so it will not replace the A-10.

The National Science Foundation has granted $11m to modify

an A-10 to perform weather research for CIRPAS at the US Naval Postgraduate

School, to continue the effort after the T-28 that was retired in 2005.

In early 2012, the USAF proposed to disband five A-10

squadrons in its budget request, in order to lessen cuts to more versatile

aircraft in a smaller future fleet.

Variants

YA-10A ... Pre-production variant. 12 were built.

A-10A ... Single-seat close air support, ground-attack

version.

OA-10A ... A-10As used for airborne forward air control.

YA-10B Night/Adverse Weather ... Two-seat experimental

prototype, for work at night and in bad weather.

The one YA-10B prototype was converted from an A-10A.

A-10C ... A-10As updated under the incremental Precision

Engagement (PE) program.

A-10PCAS ... Proposed unmanned version being developed

by Raytheon and Aurora Flight Sciences as part

of DARPA's Persistent Close Air Support program.

Operators

The A-10 has been flown exclusively by the United States

Air Force and its Air Reserve components, the Air Force Reserve Command

(AFRC) and the Air National Guard (ANG). The USAF operated 345 A-10 and

OA-10 aircraft (191 in active duty, 106 in ANG, and 48 in AFRC, all variants)

as of September 2011.

Specifications (A-10A)

| General characteristics

Crew: 1

Length: 53 ft 4 in (16.26 m)

Wingspan: 57 ft 6 in (17.53 m)

Height: 14 ft 8 in (4.47 m)

Wing area: 506 ft² (47.0 m²)

Airfoil: NACA 6716 root, NACA 6713

tip

Empty weight: 24,959 lb (11,321 kg)

Loaded weight: 30,384 lb (13,782 kg)

On CAS mission: 47,094 lb (21,361 kg)

On anti-armor mission: 42,071 lb (19,083

kg)

Max. takeoff weight: 50,000 lb (23,000

kg)

Powerplant: 2 × General Electric

TF34-GE-100A turbofans, 9,065 lbf (40.32 kN) each |

Click on image for larger view |

Performance

Never exceed speed: 450 knots (518

mph,[94] 833 km/h) at 5,000 ft (1,500 m) with 18 Mk 82 bombs

Maximum speed: 381 knots (439 mph,

706 km/h) at sea level, clean[94]

Cruise speed: 300 knots (340 mph,

560 km/h)

Stall speed: 120 knots (138 mph, 220

km/h)

Combat radius:

On CAS mission:

250 nmi (288 mi, 460 km) at 1.88 hour single-engine loiter at 5,000 ft

(1,500 m), 10 min combat

On anti-armor

mission: 252 nmi (290 mi, 467 km), 40 nm (45 mi, 75 km)) sea-level penetration

and exit, 30 min combat

Ferry range: 2,240 nmi (2,580 mi,

4,150 km) with 50 knot (55 mph, 90 km/h) headwinds, 20 minutes reserve

Service ceiling: 45,000 ft (13,700

m)

Rate of climb: 6,000 ft/min (30 m/s)

Wing loading: 99 lb/ft² (482

kg/m²)

Thrust/weight: 0.36

Armament

Guns: 1× 30 mm (1.18 in) GAU-8/A

Avenger gatling cannon with 1,174 rounds

Hardpoints: 11 (8× under-wing

and 3× under-fuselage pylon stations) with a capacity of 16,000 lb

(7,260 kg) and provisions to carry

combinations of:

Rockets:

4× LAU-61/LAU-68 rocket pods (each with 19× / 7× Hydra

70 mm rockets, respectively)

4× LAU-5003 rocket pods (each with 19× CRV7 70 mm rockets)

6× LAU-10 rocket pods (each with 4× 127 mm (5.0 in) Zuni rockets)

Missiles:

2× AIM-9 Sidewinders air-to-air missiles for self-defense

6× AGM-65 Maverick air-to-surface missiles

Bombs:

Mark 80 series of unguided iron bombs or

Mk 77 incendiary bombs or

BLU-1, BLU-27/B Rockeye II, Mk20, BL-755[97] and CBU-52/58/71/87/89/97

cluster bombs or

Paveway series of Laser-guided bombs or

Joint Direct Attack Munition (A-10C)[98] or

Wind Corrected Munitions Dispenser (A-10C)

Other:

SUU-42A/A Flares/Infrared decoys and chaff dispenser pod or

AN/ALQ-131 or AN/ALQ-184 ECM pods or

Lockheed Martin Sniper XR or LITENING targeting pods (A-10C) or

2× 600 US gallon Sargent Fletcher drop tanks for increased range/loitering

time.

Avionics

AN/AAS-35(V) Pave Penny laser tracker

pod (mounted beneath right side of cockpit) for use with Paveway LGBs

Head-up display (HUD) for improved

technical flying and air-to-ground support.

And to think, this is a smokeless gun.

click on image for larger view |

. |