| Reloading labor saving tips by Cliff Hanger #3720LR

Last month on the SASS wire there was a thread about reloading

and what is your most hated part of the process? After following this thread,

I thought I would tell you what I do to make it a little easier.

1. Separating media from brass. I have used many

things to do this. I started out by doing it by hand. Taking each and every

piece of brass and turning it so the opening was down and tapping it on

the bench top. It didn't take long to figure this was not going to be very

productive as far as trying to reload hundreds of rounds every week to

keep up with shooting a match or two every weekend. So I took an old aluminum

colander and drill the holes bigger. 1/4" Well this was better but by no

means efficient. Next I invested in one of those advertises media separators

baskets that go over a 5 gallon bucket. Better than the colander but not

much. Then looking at other separators I decided to build my own.

I started with two 12" diameter 5/8" plywood circles from

Home Depot. I drilled a 1/2" hole in the center of both. I then cut them

sort of in half. Off center by 1.5". I made an axle of 1/2" steel rod.

Welded a handle to it and a small 3" plate on the axle. The axle was inserted

through the plywood circles. I use 3/8" hardware cloth to go around the

wood circles to make a large basket. I used aluminum strips, 1/2" by 1/8"

to support the wire. I bought a big plastic tub and installed two bolts

at each end to keep the axle in place while turning. Actually I bought

the tub and made the basket to fit inside. Two latches to hold the two

halves together.

Media, small rocks and primers fall right though the hardware

cloth. A few turns of the basket and your done. BUT there is the occasional

media pieces in the case feeder on my Dillons. I fixed that by drilling

the two small holes on the bottom of the case feeder just large enough

for a large pistol primer to fall through. Then you can tape a small plastic

bag under the case feeder to catch all the media and other stuff that falls

through.

This is my media separator.

. |

The complete basket

. |

The basket opened up

. |

Looking at the end of the basket where the handle is

attached by two 1/4" bolts.

. |

Basket read for media and brass |

Dumping 500 38spl from the tumbler

in to the separator |

Showing the latch holding the two halves together and

the two bolts in the tub that the axle rides between |

Spinning the basket slowly.

About 10 turns will separate the media from the brass |

Clean brass ready for the press.

. |

2. Cleaning the lube out of the dies. This one

is very simple. Clean the lube out when it's cold. The wax is brittle and

will flake out easily. If it's summer, put the tool head in the refrigerator

over night. I pull the seating plug out and I use a small screw driver

blade. I do this first thing every morning when I go in to the shop. I

have dummy rounds made up in several calibers and various lengths. I use

them to reset the dies for the job at hand. I hear some complain about

having to adjust dies. Me, I adjust dies several times a day to fit the

job at hand. Not a problem and takes only a few seconds once I find the

right dummy round.

In the winter the lube builds up and the bullets tend

to seat deeper and deeper as you do more rounds. In the summer the lube

builds up and is soft. It gets all over the bullet nose making a mess of

things.

3. Lubing cases before sizing. I lube all

rifle caliber cases and all bottle neck cases before resizing. So here

is my process.

I have a tool head that has nothing in it. When I need

to resize brass I find the appropriate sizing die. I remove the decapping

pin and put the die in station #3. (650 Dillon) That's right....Station

#3. My reason is I do not want to punch the primer out at this

time. By doing this I don't have to have the sizing die in station #1.

Station #3 is the easiest one to get to. I can make sure the case is straight

as it goes in to the sizing die with a light touch. This reduces crushed

cases during sizing by almost 100%.

I use One Shot spray lube. I toss a hand full of brass

in a small bucket. Spray it lightly. I move the brass around in the bucket

and lightly spray again. This should cover almost all the case surface.

Now I run all the brass through the press. Once completed I have sized

but still lubed brass. I toss the brass back in to the tumblers for about

10 or 15 minutes. This removes the lube. Now back to the press.

I change out the tool head with the tool head that has

all the dies in it and powder measure. There is one exception. Station

#1 does not get a sizing die. It gets a Universal Decapping die. This die

has a very large opening. It will take 45-70 cases without touching the

case walls. The only thing this dies does is remove the primers. Remember

I left the primers in up to now. The brass has been in the tumbler twice

so far. Media tends to get stuck in the primer holes if the primer is out.

Media also gets stuck in the primer itself. So by leaving the primer in

until I am actually loading the case, the media that may be in the primer

hole or primer back will be pressed out.

After reloading the brass I shouldn't have to wipe the

rounds down to get the lube off. I did that in the tumbler between resizing

and reloading.

4. Making Dummy Rounds. If you reload several calibers

or rounds of the same caliber but different length this will help save

you time. When you clean the lube out of your bullet seating die you can

use a dummy round to get your adjustments back to within .001". Or if you

change overall length like going from a 38spl of say 1.46" to a long 38spl

of 1.54" to feed better in a lever rifle, you just back the seating plug

out a bit and run the appropriate dummy round up in to the die. Screw down

the adjustment plug hand tight and you're close. So I have Dummy rounds

in most cas calibers, several bullet shapes, bullet weights and various

lengths of each. Depends on the customer's requirements. I have my customers

try different lengths, weights and shapes until they find what works best

in their rifles at the speed they work the action. I mark this information

in my book so I can duplicate it when their brass comes in again. The pistols

don't seem to care much. They shoot what ever fits.

I have one customer that has several rifles in the same

caliber but they don't like sharing the same length rounds. I think I have

3 lengths for 5 rifles. The customer has to tell me which rifle the rounds

will be used in. Yes, we numbered each rifle to make this easier.

Last three number of serial number.

If you have any little tricks to make reloading easier

or the Dillon press work better, I would like to hear about it. I would

be happy to put that information here in the Brimstone gazette.

CH

|

4 bore from Wikipedia

| Four bore or 4 bore is an obsolete black powder caliber

of the 19th century, used for the hunting of large and potentially dangerous

game animals. The specifications place this caliber between the larger

two bore and the lesser six bore. It was the quintessential elephant gun

of the black powder safari rifles.

Specifications

The name derives out of an old English practice of bore

measurements in gun making, meaning a perfectly round pure lead ball that

exactly fits the bore of the weapon would weigh 1/4 of a pound (see gauge).

The 4 bore was made to fire roundballs of 1/4 pound lead, or approximately

1750 grains (1750 gr.) and approximately 1-inch calibre (more precisely,

1.053", when shooting pure lead bullets). This varied greatly as in muzzle

loader days shotgun gauges were custom made and often differed from the

actual bore measurements. Commonly, 4 gauges were closer to .935-.955 calibre,

pertaining to a 1400 gr. alloyed lead ball and closer to 5 gauge.

History 1750-1880

As European settlers found early on, their regular muskets

were inadequate against dangerous African game. Early gun adaptations were

to use smoothbore shotguns with extra long barrels and round balls. By

the mid-19th century, 12, 10, 8 and 4 bore muskets had been strengthened

and bulked up for much larger charges. Shooting dangerous game was still

at this stage as much about being able to gallop away on horseback to reload

and fire again, some times up to 30 times when after an elephant. |

.. .. ..

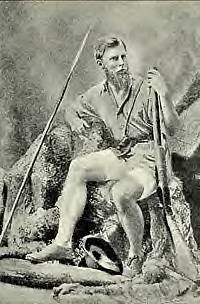

Portrait of Frederick Courteney Selous

with his 4 bore single-shot smoothbore

"gun" and African hunting regalia, 1876. |

.

.. .. |

The first 4 bores were probably single barrel muzzleloaders

converted from British fowling pieces. Loads (bullet weights and gunpowder

loads) varied greatly. As the weight and strength increased, gunpowder

loads went from 8 drams (0.5 oz) to a full ounce (16 drams), or more, of

powder. The advent of rifling after about 1860 allowed longer conical projectiles

to be stabilized, and, aside from accuracy, these provided even greater

weight and penetration, with some hardened lead or steel bullets weighing

as much as 2000 grains. The 4 bore was also occasionally used for shooting

exploding projectiles. The transition from smoothbore to rifled barrels

did not occur overnight, since dangerous game was shot at ranges under

40 yards where a smoothbore was sufficiently accurate, provided higher

velocities, and needed less cleaning. The smoothbore also, at least until

the advent of breechloading, could be reloaded faster. |

Many famous elephant hunters during the 19th century used

such weapons, including George P. Sanderson in India and William Finaughty

and Frederick Courteney Selous in Southern Africa. Sanderson, in particular,

mentioned two each four bore firearms that he used, one of which was rifled

whilst the other was not. Although both weapons were of similar weights,

the rifle was built to accommodate only one barrel with a powder charge

only five-sixths that of the smoothbore, which was a double-barrel. Sanderson,

in fact, discarded the rifle after a misfire of the weapon's cartridge

almost led to his death, and the instance demonstrated the superiority

of the smoothbore over the rifle in the case of an oversized firearm in

his day in his mind. However, once again, as rifling and steels improved,

the smoothbore was doomed to die and be replaced completely by rifled breechloading

4 bores in the 1880s. With the advent of breechloading cases in the

late 19th century the 4 bore came into its current guise, that being the

well-known 4-4.5" brass case.

Smoothbores became a lesser choice, as did muzzleloaders.

The cartridge brass case was around 4 inches (100 mm)

long, and contained three types of loads: light at 12 drams, 14 drams at

regular, and 16 drams of powder at heavy load. (Note: 1 dram = 27.34375

grains in the avoirdupois system, since 256 drams = 7000 grains = 1 pound

of powder. Shotgun shells are still rated in terms of the same archaic

dram measurements, relative to their equivalence of smokeless powder load

to a blackpowder load weighed in drams.) John "Pondoro" Taylor mentioned

in his book African Rifles and Cartridges that the 12 drams (328 gr., 3/4

oz.) charge would propel the projectile at around 1330 fps. A double barreled

rifle that would fire such a calibre would weight around 22-24 lbs bare,

while the single-barreled version would be around 17-18 lbs. In common

practice, the cartridge cases were not typically reloaded, as reliability

was of the utmost importance, more important than a possible false cost

savings from an attempt at reloading that might cost a hunter his life.

Bullet lubrication was typically mostly beeswax based, such that in hot

tropical climes there could be no possibility of a bullet lube melting

from the base of the bullet, ruining the charge of powder within the cartridge.

Reliability was the utmost concern.

Golden Age and later usage

This caliber was used heavily by the European hunters,

notably so British, in tropical climates of Africa and India. Meant to

be used with black powder due to its size, it was unpopular due to the

problem of thick smoke and a powerful recoil. Notable hunters that used

the rifles included Sir Samuel White Baker and Frederick Selous, who used

it consistently in his career as an ivory hunter of African elephants between

1874 and 1876 until the advent of the lighter, more accurate and less cumbersome

Nitro Express calibers and cordite propellant. In the mid 1870s, Selous

favoured a four bore black powder muzzleloader for killing elephant, a

13 lbs short barreled musket firing a quarter pound bullet with as much

as 20 drams (540 grains) of blackpowder. He could wield it even from horseback.

Between 1874 and 1876, he slew exactly seventy-eight elephants with that

gun, but eventually there was a double loading incident together with other

recoil problems from it, and he finally gave it up as too "upsetting my

nerve".

| Although a weapon of immense power, the four bore was

far less effective than its Nitro Express successors because of the low

penetration of its projectiles and its immense recoil. The huge lead slugs

fired by the gun were sometimes capable of stunning a charging African

elephant to stop it on its tracks, or turn its charge(causing it to change

direction to avoid the hunter)but it was generally unable to kill the creature

outright with a frontal brain shot.

Chest and broadside shots were effective killers, as was

the side shot on brain where the skull is thinner on elephant, however

once again this did not help for instantly stopping an enraged elephant

charging the hunter. On the other dangerous game species such as the Indian

elephant, buffalo species and Rhino it was considered an excellent killer.

The use of four bore elephant guns in fiction, such as in Allan Quatermain,

the sequel to King Solomon's Mines, was a common theme during the Golden

Age of African hunting and in Lost World type adventure stories published

in the late 19th Century and early 20th Century. The four bore also figures

prominently in more recent fiction, such as Unintended Consequences. |

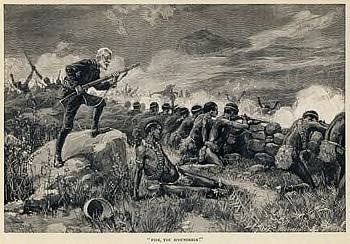

Allan Quatermain, having waited until the last minute

while

holding his elephant gun, orders his men to fire in this

illustration

by Thure de Thulstrup from Maiwa's Revenge (1888). |

|

| 2 bore from Wikipedia (thought

this went nicely with the 4 bore. I especially like the comments at the

end)

The two bore or 2 bore is a mostly

obsolete firearm caliber.

Specifications

The two bore fired spherical balls

or slugs of hardened lead or, in more modern cartridges, a solid bronze

projectile. The gauge was 1.32 inches (34 mm), and the projectiles generally

weighed about 8 ounces (225 grams; 3500 grains). The velocity was relatively

low, at its best around 1,500 feet per second (460 m/s) at the muzzle,

but hit with approximately 17,500 ft·lbf (23,700 J) of energy.

History and background

The largest size ever created for

a shoulder rifle, and used mainly in the 19th century for hunting large

and potentially dangerous game animals, this caliber was used by the European

hunters, notably the British, in tropical climates of Africa and India.

Meant to be used with black powder due to its size, it was unpopular due

to the problem of thick smoke and a powerful recoil. The rifle was meant

to be fired from the shoulder by one person; larger guns existed, such

as the punt gun, but these were only fired supported and generally from

a prone position. Sir Samuel White Baker, a notable British explorer and

hunter of the Victorian era, was impressed by its power, but heavily disapproved

of the recoil. He narrates dashing adventures with his two-bore rifle,

which he affectionately referred to as "Baby" :

| “Among other weapons, I had an

extraordinary rifle that carried a half-pound percussion shell; this instrument

of torture to the hunter was not sufficiently heavy for the weight of the

projectile: it only weighted twenty pounds, thus with a charge of ten drachms

[270 grains] of powder and a HALF-POUND shell, the recoil was so terrific,

that I spun around like a weathercock in a hurricane. I really dreaded

my own rifle, although I have been accustomed to heavy charges of powder

and severe recoils for some years. None of my men could fire it, and it

was looked upon as a species of awe, and it was name "Jenna-El-Mootfah"

(Child of a Cannon) by the Arabs, which being a far too long of a name

for practice, I christened it the "Baby", and the scream of this "Baby"

loaded with a half-pound shell was always fatal. It was too severe, and

I seldom fired it, but it is a curious fact that I never shot a fire with

that rifle without bagging. The entire practice, during several years,

was confined to about twenty shots. I was afraid to use it, but now and

then as it was absolutely necessary, it was cleaned after months of staying

loaded. On such occasions my men had the gratification of firing it, and

the explosion was always accompanied by two men falling on their backs

(one having propped up the shooter) and the "Baby" flying some yards behind

them. This rifle was made by Holland & Holland, of Bond Street, and

I could highly recommend it for the Goliath of Gath, but not for the men

of A.D. 1866." |

|

All articles submitted to the "Brimstone

Gazette" are the property of the author, used with their expressed permission.

The Brimstone Pistoleros are not

responsible for any accidents which may occur from use of loading

data, firearms information, or recommendations published on the Brimstone

Pistoleros web site. |

|