| Chimney Rock had been quiet,

almost too quiet in the time since the last big mineral

cycle caused the town to boom, with violent results. But now, the easy

money was gone from the town and gone too were most of the bad men and

wild women that bring a colorful, if sometimes raucous energy to a town.

But like the storm clouds building up in the mountains

there was a change building in the town. An old miner, exploring his played

out claim had chanced upon some strange symbols cut into freshly exposed

rock, a box with a cross above it and a triangle in a circle. With further

investigation the old miner found a small strong box with an old pistol

with a J carved into the grips, a quantity of gold and silver coins, a

journal and some strangely marked maps.

The old miner was cagey but he couldn't read. So he hid

most of the gold and most of the maps and took the pistol and the journal

back to town to get

someone to read from it in hopes of finding out more

about this strange find. Little did the old miner suspect that the journal

he had found belonged to none other than Jesse James and the markers and

the maps held the keys to a Civil War treasure, hidden in the hills by

members of the Knights of the Golden Circle, a Southern group who were

known to have hidden money and arms throughout the South and Southwest

in order for the Confederacy to take over Northern Mexico, and later to

keep the hopes of the South alive in the waning days of the conflict with

the North.

The only person the old miner knew could read in the town

of Chimney rock was Thomas Francis Shelby, a barber and dentist from Missouri

who had fought in the civil war and who knew the meaning of the symbols

and the importance of the journal as soon as the Old miner showed them

to him. Convincing the old man to show him the symbols T. F. Shelby accompanied

the miner to his old claim and upon seeing the marks in the rocks shot

the old man in the back, leaving him to die in the hills.

While Shelby rode back to Chimney Rock, the old miner,

tougher than he looked dragged himself up toward his old cabin. Before

getting there he was

found by a passing stranger and the old man told him

his story and knowing he was about to die, trusted him with the secret

of the maps and asked the

stranger to make sure that he was buried proper and that

the money, if there was any was sent to his daughter he had left behind

back in St. Louis.

The stranger promised the old miner that his wishes would

be met and after he buried him and located the maps, the stranger went

down to town to serve

justice.

Meanwhile, Shelby had been burning up the telegraph wires,

contacting relatives and shadowy men who begin the trip to Chimney Rock

and the promise

of treasure, and violence. Once again it seemed that

Chimney Rock was to be the site of a clash of wills and witness to the

flash, smoke and thunder of

a battle. |

| Rifling from Wikipedia

Rifling refers to the helix-shaped

pattern in the barrel of a firearm, which imparts a spin to a projectile

around its long axis. This spin serves to gyroscopically stabilize the

projectile, improving its aerodynamic stability and accuracy.

Rifling is described by its twist

rate, which indicates the distance the bullet must travel to complete one

full revolution, such as "1 turn in 10 inches" (1:10 inches), or "1 turn

in 30 cm" (1:30 cm). A shorter distance indicates a "faster" twist, meaning

that for a given velocity the projectile will be rotating at a higher spin

rate.

The length of a projectile determines

the twist rate needed to stabilize it - barrels intended for short, large-diameter

projectiles like spherical lead balls require a very low twist rate, such

as 1 turn in 48 inches (122 cm). Barrels intended for long, small-diameter

bullets, such as the ultra-low-drag, 80-grain 0.224 inch bullets (5.2 g,

5.56 mm), use twist rates of 1 turn in 8 inches (20 cm) or faster.

In some cases, rifling will have

twist rates that increases down the length of the barrel, called a gain

twist; a twist rate that decreases from breech to muzzle is undesirable,

as it cannot reliably stabilize the bullet as it travels down the bore.

Extremely long projectiles such as flechettes may require impractically

high twist rates; these projectiles must be inherently stable, and are

often fired from a smoothbore barrel.

Rifling of a Canon de 75 modèle 1897 |

Rifling in a .35 Remington microgroove rifled barrel |

Manufacture

| Most rifling is created by either:

* cutting one

groove at a time with a machine tool (cut rifling or single point cut rifling);

* cutting all

grooves in one pass with a special progressive broaching bit (broached

rifling);

* pressing all

grooves at once with a tool called a "button" that is pushed or pulled

down the barrel

(button rifling);

* forging the

barrel over a mandrel containing a reverse image of the rifling, and often

the chamber as well (hammer forging);

* flow forming

the barrel preform over a mandrel containing a reverse image of the rifling

(rifling by flow forming) |

Rifling in a French 19th century

cannon |

The grooves are the spaces that are

cut out, and the resulting ridges are called "lands". These lands and grooves

can vary in number, depth, shape, direction of twist ("right" or "left"),

and "twist rate" (turns per unit of barrel length). The spin imparted by

rifling significantly improves the stability of the projectile, improving

both range and accuracy. Typically rifling is a constant rate down the

barrel, usually measured by the length of travel required to produce a

single turn. Occasionally firearms are encountered with a gain twist, where

the rate of spin increases from chamber to muzzle. While intentional gain

twists are rare, due to manufacturing variance, a slight gain twist is

in fact fairly common. Since a reduction in twist rate is very detrimental

to accuracy, gunsmiths who are machining a new barrel from a rifled blank

will often measure the twist carefully so they may put the faster rate,

no matter how minute the difference is, at the muzzle end (see internal

ballistics for more information on accuracy and bore characteristics).

Construction and operation.

| A barrel of circular cross-section

is not capable of imparting a spin to a projectile, so a rifled barrel

has a non-circular cross-section. Typically the rifled barrel contains

one or more grooves that run down its length, giving it a cross-section

resembling a gear, though it can also take the shape of a polygon, usually

with rounded corners. Since the barrel is not circular in cross-section,

it cannot be accurately described with a single diameter. Rifled bores

may be described by the bore diameter (the diameter across the lands or

high points in the rifling), or by groove diameter (the diameter across

the grooves or low points in the rifling.) Differences in naming conventions

for cartridges can cause confusion; for example, the .303 British is actually

slightly larger in diameter than the .308 Winchester, because the ".303"

refers to the bore diameter in inches, while the ".308" refers to the groove

diameter in inches (7.70 mm and 7.82 mm, respectively.) |

Conventional rifling (left) and

polygonal rifling (right)

More on Polygonal Rifling to follow

this article |

Despite differences in form, the common

goal of rifling is to deliver the projectile accurately to the target.

In addition to imparting the spin to the bullet, the barrel must hold the

projectile securely and concentrically as it travels down the barrel. This

requires that the rifling meet a number of tasks:[4]

1. It must be sized

so that the projectile will swage or obturate upon firing to fill the bore.

2. The diameter should

be consistent, and must not increase towards the muzzle.

3. The rifling should

be consistent down the length of the bore, without changes in cross-section,

such as variations in groove width or spacing.

4. It should be smooth,

with no scratches lying perpendicular to the bore, so it does not abrade

material from the projectile.

5. The chamber and

crown must smoothly transition the projectile into and out of the rifling.

When the projectile is swaged into

the rifling, it takes on a mirror image of the rifing, as the lands push

into the projectile in a process called engraving. Engraving takes on not

only the major features of the bore, such as the lands and grooves, but

also minor features, like scratches and tool marks. The relationship between

the bore characteristics and the engraving on the projectile are often

used in forensic ballistics.

Fitting the projectile to the bore

The original firearms were loaded

from the muzzle by forcing a ball from the muzzle to the breech. Whether

using a rifled or smooth bore, a good fit was needed to seal the bore and

provide the best possible accuracy from the gun. To ease the force required

to load the projectile, these early guns used an undersized ball, and a

patch made of cloth, paper, or leather to fill the windage (the gap between

the ball and the walls of the bore.) The patch provided some degree of

sealing, kept the ball seated on the charge of black powder, and kept the

ball concentric to the bore. In rifled barrels, the patch also provided

a means to transfer the spin from the rifling to the bullet, as the patch

is engraved rather than the ball. Until the advent of the hollow-base Minié

ball, which obturates upon firing to seal the bore and engage the rifling,

the patch provided the best means of getting the projectile to engage the

rifling.

In breech-loading firearms, the

task of seating the projectile into the rifling is handled by the throat

of the chamber. Next is the freebore, which is the portion of the throat

down which the projectile travels before the rifling starts. The last section

of the throat is the throat angle, where the throat transitions into the

rifled barrel.

The throat is usually sized slightly

larger than the projectile, so the loaded cartridge can be inserted and

removed easily, but the throat should be as close as practical to the groove

diameter of the barrel. Upon firing, the projectile expands under the pressure

from the chamber, and obturates to fit the throat. The bullet then travels

down the throat and engages the rifling, where it is engraved, and begins

to spin. Engraving the projectile requires a significant amount of force,

and in some firearms there is a significant amount of freebore, which helps

keep chamber pressures low by allowing the propellant gases to expand before

being required to engrave the projectile. Best accuracy, however, is typically

provided with a minimum of freebore, maximizing the changes that the projectile

will enter the rifling without distortion.

Twist rate

For best performance, the barrel

should have a twist rate sufficient to stabilize any bullet that it would

reasonably be expected to fire, but not significantly more. Large diameter

bullets provide more stability, as the larger radius provides more gyroscopic

inertia, while long bullets are harder to stabilize, as they tend to be

very backheavy and the aerodynamic pressures have a longer "lever" to act

on. The slowest twist rates are found in muzzleloading firearms meant to

fire a round ball; these will have twist rates as low as 1 in 60 inches

(1,500 mm), or slightly longer, although for a typical multi-purpose muzzleloader

rifle, a twist rate of 1 in 48 inches (1,200 mm) is very common. The M16A2

rifle, which is designed to fire the SS109 bullet, has a 1 in 7-inch (180

mm) twist. Civilian AR-15 rifles are commonly found with 1 in 12 inches

(300 mm) for older rifles and 1 in 9 inches (230 mm) for most newer rifles,

although some are made with 1 in 7 inches (180 mm) twist rates, the same

as used for the M16. Rifles, which generally fire longer, smaller diameter

bullets, will in general have higher twist rates than handguns, which fire

shorter, larger diameter bullets.

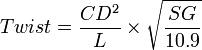

George Greenhill, a mathematician

at Emmanuel College, Cambridge, UK, developed a rule of thumb for use in

calculating twist rates for a given lead-core bullet. The formula, named

the Greenhill Formula in his honour, is:

where:

* C = 150 (use 180 for muzzle velocities

higher than 2,800 f/s)

* D = bullet's diameter in inches

* L = bullet's length in inches

* SG = bullet's specific gravity (10.9

for lead-core bullets, which cancels out the second half of the equation)

The original value of C was 150, which yields a twist

rate in inches per turn, when given the diameter D and the length L of

the bullet in inches. This works to velocities of about 840 m/s (2800 ft/s);

above those velocities, a C of 180 should be used. For instance, with a

velocity of 600 m/s (2000 ft/s), a diameter of 0.5 inches (13 mm) and a

length of 1.5 inches (38 mm), the Greenhill formula would give a value

of 30, which means 1 turn in 30 inches (760 mm).

| If an insufficient twist rate is used, the bullet will

begin to yaw and then tumble; this is usually seen as "keyholing", where

bullets leave elongated holes in the target as they strike at an angle.

Once the bullet starts to yaw, any hope of accuracy is lost, as the bullet

will begin to veer off in random directions as it precesses.

Conversely, too-high a rate of twist can also cause problems.

The excessive twist can cause accelerated barrel wear, and also induce

a very high spin rate which can cause high-velocity projectiles to disintegrate

in flight. A higher twist than needed can also cause more subtle problems

with accuracy: Any inconsistency within the bullet, such as a void that

causes an unequal distribution of mass, may be magnified by the spin. Undersized

bullets also have problems, as they may not enter the rifling exactly concentric

and coaxial to the bore, and excess twist will exacerbate the accuracy

problems this causes. Lastly, excessive spinning causes a reduction in

the lateral kinetic energy of a projectile, thereby reducing its destructive

power (the energy instead becomes rotational kinetic energy). |

A Parrott rifle, used by both Confederate and Union forces

in the American Civil War |

Recent developments

The grooves most commonly used in modern rifling have

fairly sharp edges. More recently, polygonal rifling, a throwback to the

earliest types of rifling, has become popular, especially in handguns.

Polygonal barrels tend to have longer service lives because the reduction

of the sharp edges of the land reduces erosion of the barrel. Supporters

of polygonal rifling also claim higher velocities and greater accuracy.

Polygonal rifling is currently seen on pistols from Heckler & Koch,

Glock and Kahr Arms, as well as the Desert Eagle.

For tanks and artillery pieces, the extended range, full

bore concept developed by Gerald Bull for the GC-45 howitzer reverses the

normal rifling idea by using a shell with small fins that ride in the grooves,

as opposed to using a slightly oversized projectile which is forced into

the grooves. Such guns have achieved significant increases in muzzle velocity

and range. Examples include the South African G5 and the German PzH 2000.

|

| Polygonal rifling from Wikipedia

Polygonal rifling is a type of rifling

wherein the traditional lands and grooves are replaced by "hills and valleys"

in a rounded polygonal pattern, usually a hexagon.

Conventional eight groove rifling on the left, and octagonal

polygonal rifling on the right |

History

While polygonal rifling has been

around since the earliest days of rifled barrels, it had faded out of use

by the time of the early cordite cartridges. The last common rifle to use

polygonal rifling was the Lee-Metford rifle, named after the Metford rifling,

a 7 sided polygonal type rifling. The switch to cordite from black powder

proved too much for the shallow rifling in the relatively soft barrels

of the time, and the Lee-Metford became the Lee-Enfield when the Metford

rifling was dropped. Heckler & Koch was the first manufacturer to begin

using polygonal rifling in modern arms. Companies that utilize this method

today include Heckler & Koch, Glock, Magnum Research, Noveske Rifleworks

and Kahr Arms. Polygonal rifling is usually only found in pistol barrels,

and is less common in rifles, However some extremely high end rifles like

the PSG-1 use polygonal bores.

The term "polygonal rifling" is

fairly general, and different manufacturers employ varying polygonal rifling

profiles.

Advantages

A number of advantages are claimed

by the supporters of polygonal rifling. These include:

* Higher velocities

due to reduced friction of the bullet in the barrel, as the polygonal rifling

has less surface area than the lands and grooves of a traditionally rifled

barrel

* Less bullet

deformation, resulting in reduced drag on the bullet which helps to increase

range and accuracy

* Increased

barrel life and reduced buildup of copper or lead within the barrel

However, precision target pistols

such as those used in bullseye and IHMSA almost universally use traditional

rifling, as do target rifles. The debate among target shooters is almost

always one of cut vs. button rifled barrels, as traditional rifling is

dominant. Polygonal rifled barrels are used competitively in pistol action

shooting, such as IDPA and IPSC competitions.

Part of the difference may be that

most polygonal rifling is produced by hammer forging the barrel around

a mandrel containing a reverse impression of the rifling. Hammer forging

machines are tremendously expensive, far out of the reach of custom gunsmiths

(unless they buy pre-rifled blanks), and so are generally only used for

production barrels by large companies. The main advantage of a hammer forging

process is that it can rifle, chamber, and contour a bored barrel blank

in one step. First applied to gun barrel rifling in Germany in 1939, hammer

forging has remained popular in Europe, but was only later used by gunmakers

in the United States. The hammer forging process produces large amounts

of stress in the barrel that must be relieved by careful heat treatment,

a process that is less necessary in a traditionally cut or button rifled

barrel. Due to the potential for residual stress causing accuracy problems,

precision shooters tend to avoid hammer forged barrels, and this limits

them in the type of available rifling.

Lead bullets and polygonal rifling

The manufacturer Glock advises against

using lead bullets (meaning bullets not covered by a copper jacket) in

their polygonally rifled barrels, which has led to a widespread belief

that polygonal rifling is not compatible with lead bullets. Noted firearms

expert and barrel maker, the late Gale McMillan, has also commented that

lead bullets and polygonal rifling are not a good mix. However, since neither

H&K nor Kahr recommend against lead bullets in their polygonal rifled

barrels, it is probable that there is an additional factor involved in

Glock's warning. One explanation is that Glock barrels have a fairly sharp

transition between the chamber and the rifling, and this area is prone

to lead buildup if lead bullets are used. This buildup may result in failures

to fully return to battery, allowing the gun to fire with the case not

fully supported by the chamber, leading to a potentially dangerous case

failure. The other explanation is that Glock's barrels may be more prone

than normal to leading, which is the buildup of lead in the bore that happens

in nearly all firearms firing high velocity lead bullets. This lead buildup

must be cleaned out regularly, or the barrel can become constricted and

result in higher than normal pressures.

|