| Reloading Blackpowder Shotshells with Antique Tooling – No 3

by Red Sun SASS#635

Welcome back to this series of articles. This month we'll

cover some historical tidbits, priming the hull, and the components that

will be loaded. Well close with a series of photos showing the tools we'll

use for the loading process. Now let's get started with some of the priming

tools that were around back then and the one that will be used for priming.

Last month, we showed a few priming tools (cappers and

decappers) that were considered “bench top” styles. Below are some of the

more rudimentary “clamp” configurations.

The tools pictured are (L-R) BGI (Bridgeport Gun Implement

Company) Berdan primer tool, unmarked clamshell priming tool, and 2 BGI

priming tools. Below is a detail of the 2 BGI tools and their differing

priming post diameters.

As you can see, the differences are significant. We will

use the larger black handled tool for seating the 209 primer of our shotshell

hull. This larger post will safely support the base of the modern battery

cup design for our purposes. The process is shown below.

Now that we have the primer installed with this tool,

let's take a look at some of tools that will be used to measure and dispense

the powder and shot. Shown below are a few types from that vintage era.

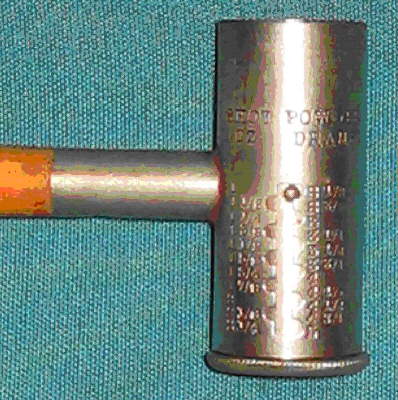

Most of these powder and shot “dippers” as they were sometimes

referred to were dual purpose since the standard rule of thumb with black

powder was equal volumes of powder to shot. Below is a close-up of the

graduations on one of them. Most of these tools had markings for both powder

and shot. Powder indicated in Drams and Shot in ounces (oz). The one pictured

below shows the graduations. These were simply adjusted by the “Cup Base”

where one would twist the marker out of the indentation and slide the internal

cup in or out.

|

Shot and Powder Graduations

Adjustment Marker

Cup Base

|

We plan to use this with the settings at 1 oz of shot

and 2 ½ Drams of powder. The powder weight equivalent is approximately

60-65 grains by weight.

Next we have the tools used to support the hull and pack

the components once they're dispensed. You've probably seen some of these

so-called plunger and funnel tools and thought about how they were utilized.

The actual name for these tools as a group is called the “Barclay Loader”.

Below is a set offered by BGI that we'll be using.

The tool set is comprised of the Plunger unit that can

also be reconfigured as a primer de-capper. The post is simply twisted

out and reversed on the handle. This is shown below.

If you're wondering what that hockey puck was for, it

used to support the base of the hull during the decapping process. The

photo to the right shows a vintage hull and a primer that would be supported

by this tool. Notice the size of the hole and the primer itself compared

to the conventional 209 primer of today. Also, you'll see how much smaller

the decapping pin is in the post. These were intended for the earlier vintage

primers that were quite a bit smaller than the conventional battery cup

configuration used today.

In preparing for the component loading, we'll insert the

hull into the funnel and place it on the base.

Now we'll gather the components that we'll use and the

sequence to how they will be installed. Below is the whole ensemble of

the items. The shot cup is the remaining cup portion of a Winchester 1

oz wad with the spring base and gas seal cut off. We also have a punched

milk carton card and a fiber wad/seal that replaces the spring and gas

seal cut off from the plastic wad. And last, there is the over-shot card

that's need prior to the roll crimping. The powder and shot are shown in

their “dumped” piles for illustration.

So with the hull installed in the funnel, we can start

loading each of these components. Next month we'll have a series of photos

showing the loading of these components and the final roll crimping of

the shotshell.

In the meantime, your comments and suggestions are welcome.

Please forward those to Redsun635@aol.com.

Happy Reloading,

Red Sun

|