THE

PETTENGILL PERCUSSION ARMY REVOLVER

AND IT'S SIBLING

THE

RODGERS AND SPENCER PERCUSSION ARMY REVOLVER

by

David Radcliff |

| A TWO PART

RAMBLING OF TWO REVOLVERS WITH THE SAME FRONT END! |

TOP: THE RODGERS AND

SPENCER .44 CALIBER SINGLE ACTION PERCUSSION ARMY

BOTTOM: THE PETTENGILL

.44 CALIBER DOUBLE ACTION PERCUSSION ARMY REVOLVER (See

Part 1) |

__________________________________________________________________________________________

PART

2

THE

ROGERS & SPENCER

SINGLE

ACTION PERCUSSION ARMY REVOLVER |

In 1864, after producing the ill fated

Pettengill Army and Navy size revolvers, Rogers and Spencer started to

produce a much improved firearm bearing their name. They basically retained

the forward part of the frame, barrel and loading lever assemblies of the

Pettengill Percussion Army Revolver probably utilizing the same machinery

to manufacture both. On November 29, 1864, Rogers, Spencer & Company

received a War Department contract for 5,000 of their revolvers at a cost

of $12.00 each. The contract called for 500 to be delivered in January

of 1865 and 500 more per each month thereafter until all of the arms were

delivered. They met the contract terms delivering the last 500 in September

of 1865 approximately 4 months after the cessation of hostilities. The

particular weapon pictured here, serial number 2879, was probably delivered

in June of 1865. Despite the Rodgers & Spencer being among the

best of the percussion military revolvers ever produced none of them were

issued for field service during or after the war. All 5,000 of them were

kept in storage in New York until 1901. At that time the entire lot of

them were sold at auction at a cost to the bidder of around $ .50 each.

Due to this, today we find many of these revolvers in new or nearly new

condition. However, some are also found that show hard usage indicating

that some people found them useful after all. The total number of Rogers

and Spencer arms produced, based on existing serial numbers, was approximately

5,800 indicating that some were likely sold on the commercial market.

RIGHT &

LEFT SIDE VIEWS OF THE ROGERS AND SPENCER .44 CALIBER SINGLE ACTION

PERCUSSION ARMY REVOLVER |

__________________________________________________________________________________________

LEFT SIDE VIEW OF

THE SPENCER & ROGERS ARMY REVOLVER WITH THE COMBINATION LOADING LEVER

/ CYLINDER ARBOR MECHANISM, LEFT AND RIGHT SET SCREWS AND CYLINDER

REMOVED |

This single action, six-shot arm is .44

caliber and weighs 3 pounds. Measured diagonally from the tip of the butt

to the muzzle face it is 14-1/4" overall. The 7-1/2" barrel is rifled with

5 grooves. The barrel is marked on the top strap "ROGERS & SPENCER

/ UTICA N.Y" in two lines. A government inspectors mark of a "B" is stamped

on both the left and right barrel flats near the frame housing. Centered

on the bottom of the barrel is the serial number, "2879". An "0" is stamped

to the rear of the loading lever catch located 1-1/2" on center from the

muzzle. The inspector's "B" stampings are also on both the left and right

sides of the upper forward frame, on the left frame below the hammer, and

at the bottom of the frame to the rear of the trigger guard screw. It is

also stamped on the left side of the hammer and the left side of the combination

loading lever and cylinder arbor near the frame as well as towards the

rear of the cylinder between two of the beveled, semi-circular nipple wells,

and in front of the mis-stamped serial number on the cylinder. That stamping

consists of an upside down "3" followed by "879". The correct serial number

stamping of "2879" is also on the left frame under the cylinder opening,

on the bottom of the grip strap, on the top of the combination loading

lever and cylinder arbor assembly (twice) and inside both grips. On the

bottom of the frame in front of the trigger guard screw is the stamping

of a small shield. The cartouche of the inspector's initials is stamped

in the left grip of the two-piece, oil-finished walnut grips. Although

quite faint they are "RPB" for Robert P. Barry, Captain U.S.A., 1860-1865.

"ROGERS & SPENCER

/ UTICA N.Y" STAMPING -TOP OF FRAME

(ALSO NOTE SIGHTING

GROOVE) |

"B"

INSPECTOR'S MARKINGS LEFT AND RIGHT SIDE BARREL FLATS & FRAME, LEFT

SIDE

LOADING

LEVER, HAMMER AND TRIGGER GUARD PLUS SHIELD STAMPING |

__________________________________________________________________________________________

"B" ON CYLINDER BETWEEN

NIPPLE WELLS |

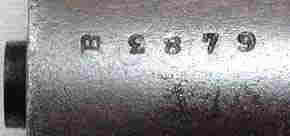

SERIAL NUMBER "2879"

STAMPING CYLINDER* AND LEFT FRAME (* MIS-STAMPED) |

NUMBER "0" AND SERIAL

NUMBER "2879"ON BOTTOM BARREL FLAT |

CLOSE UP OF MIS-STAMPED

SERIAL NUMBER (UPSIDE DOWN "3" PLUS "879") |

ERIAL NUMBER "2879"

ON BUTT STRAP |

SERIAL NUMBER "2879"

ON RAM ROD / CYLINDER ARBOR PIN |

SERIAL NUMBER "2879"INSIDE

GRIPS |

LEFT GRIP CARTOUCHE

(FAINT)

("RPB" for Robert

P. Barry, Captain U.S.A., 1860-1865) |

__________________________________________________________________________________________

There is a high German silver cone

front sight set 3/8", on center, from the muzzle face. The rear sight is

formed by a pinched "V" groove formed into the top strap. The blued, solid

frame is marked as described above. At the front of the cylinder the frame

drops vertically enclosing the barrel threads. There is a cone shaped loading

groove at the lower right of the frame. A somewhat flat recoil shield behind

the cylinder is cast integral to the frame. A semi-circular capping groove

is present in the right side recoil shield. The hammer was originally case-hardened.

The blued six chamber 2 inch long cylinder has rectangular shaped stop

slots. The nipples are recessed in beveled, semi-circular wells. The one

piece grip straps and trigger guard are blue finished as is the trigger.

The two screws at the rear of the frame serve to properly position the

grip straps. The case-hardened loading lever has a plunger type latch that

is held by a catch mortised into the bottom of the barrel 1-1/2" from the

muzzle. The loading lever/cylinder arbor assembly is held in place by set

screws which enter the frame from each side just forward of the cylinder.

These set screws must be removed to free the cylinder. The black walnut

two piece grips flare out quite noticeably at the butt giving this arm

a unique appearance.

If I have one criticism of this arm,

it is the set screws. It is always easier to load the cylinder when it

is out of the gun. The user would need a screw driver to remove these set

screws if he wished to take the cylinder out each time he loaded the weapon.

A prospect fraught with problems when in the field.

FRONT CONE SIGHT |

SET SCREWS FOR RELEASING

LOADING LEVER / CYLINDER ARBOR |

|

|

| LEFT & RIGHT SIDE

VIEWS - BARREL, LOADING LEVER & FRONT OF FRAME |

FRONT CYLINDER VIEW |

REAR CYLINDER VIEW |

TOP & BOTTOM OVERALL

VIEWS |

__________________________________________________________________________________________

Reference material for this posting

came from "U.S. Military Small Arms 1816-1865" by Robert M. Reilly, "Civil

War Small Arms", an American Rifleman Reprint - Articles "Civil War Revolvers

Part 1 & 2 of 2" by C. Meade Patterson & Cuddy De Marco, Jr. and

Norm Flayderman's "Flayderman's Guide To Antique American Firearms... And

Their Values".

The photographs are all originals of

mine as are any assumptions or errors in this posting. The ace webmaster

is Reed Radcliffe, my son, who puts this all together for your viewing.

GOD BLESS AMERICA!!

Dave Radcliffe

==============================================

Permission to reprint this article

given by

Antique and Collectable Firearms

and Militaria Headquarters

http://OldGuns.net

sponsors of http://ArmsCollectors.com

where many similar stories are located, as well as the Springfield Research

Service site to look up documented history of U.S. miltiary small arms

based on serial numbers. |

| Getting a Grip by Cliff Hanger

At so many matches I see shooters at the firing line wiping

their hands off before they start. It's not those that wipe their hands

once but those that keep doing it over and over before saying they're ready.

Most of this is most likely nerves. And with this nervousness comes sweaty

hands.

What I would like to share at this time with those of

us that have this problem at times is a simple little trick I learned in

a jr high science class. Along with all the other science stuff, the teacher

explained the reasons we get sweat hands and how to control it. His example

was, "What to do when you go for your job interview!" You do not want to

shake hands with anyone when you have sweaty hands. All us kids thought

this was silly. As the lesson went on he said no one would go to an interview

without first taking a bath and putting on clean clothes. As the time gets

closer to the interview everyone tends to get nervous. The first signs

are your palms getting damp. His little secret to controlling this was

simple. As you get dress, take the same deodorant you use and put it on

your palms. This will stop the perspiration on your hands.

Now using this little trick in our sport you will now

have better gun control. You will have to learn to grip your guns correctly

before using them. This is because your hands will no longer slip. To change

your grip if it should need adjusting, you will actually have to release

your grip. Reposition the gun and regrip it.

Another suggestion is to use an unscented spray on. This

stops the funny looks you will no doubt get from the perfumed hand you

will have if you do not use an unscented product. |

| Ahoy, Brass Shot Shells by

Engineer BILL

I had a nice chat with Beartrap Bandit and he shared with

me the following info for publication regarding brass shot shells. I bought

a box of 25 for $13.99

Magtech brass

Inexpensive brass shells. Use lg pistol primers ,11ga

overpowder and cushion wads & 10 ga overshot card. Can be roll crimped

to feed easier.

Available from Midway Supply.

Rocky Mountain Cartridge Co. www.rockymountaincartridge.com

307-587-9693

Expensive but almost indestructible shells. Use 209 primers

and all wads are 12ga. Are heavy and slide out easily. Also make a handy

reloading kit for about $35. Website has useful reloading instructions.

RCBS

www.rcbs.com

800-533-5000

Makes a 12 gauge shell holder. It’s not listed in parts

book but you can call to order.

Track of the Wolf

www.trackofthewolf.com

763-633-6785

Good source for CircleFly wads.

Dixie Gun Works

www.dixiegunworks.com

800-238-6785

Another source for wads and other stuff.

DUCO cement

Available at Ace Hardware, Home Depo, Walmart, Etc.

Works well for glueing in overshot card. Comes in a Green

tube.

Midway USA

www.midwayusa.com

800-243-3220

Good source for Magtech brass and reloading tools/supplies

CircleFly wads

www.circlefly,com

717-862-3600

Very good quality wads. Site also has useful info on

reloading.

Lee Improved Powder Measure Kit

Available from Midway

Best $7 investment you’ll make!

C-H Tool & Die Co.

www.ch4d.com

740-397-7214

Make both a sizing/depriming & roll crimp die for

magtech brass. BIG dies and you must remove the adapter nut in a Rockchucker

to use (11/2“ wrench).

Make sure to use plenty of case lube! Expensive but work

great and may pay off if you shoot a lot of brass.

Ebay

www.ebay.com

Good source for reloading tools. Try searches for “antique

reloading”, “vintage reloading”. “old reloading”’ etc. Be a nice guy and

don’t try to outbid me though!

Hammer Double Shells

www.hammerdouble.com

800-543-5988

Make “crown series” brass shells using what appears to

be magtech brass but come with 209 primers already installed and in a nice

plastic box. Somewhat

pricey though!

|

All articles submitted to the "Brimstone

Gazette" are the property of the author, used with their expressed permission.

The Brimstone Pistoleros are not

responsible for any accidents which may occur from use of loading

data, firearms information, or recommendations published on the Brimstone

Pistoleros web site. |

|