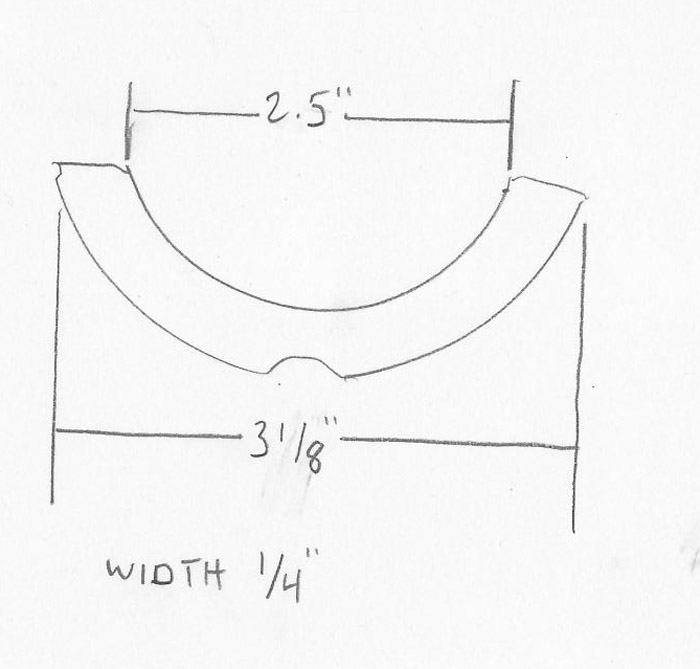

| Frames for a Blueback.

Drawing received from Farlan.

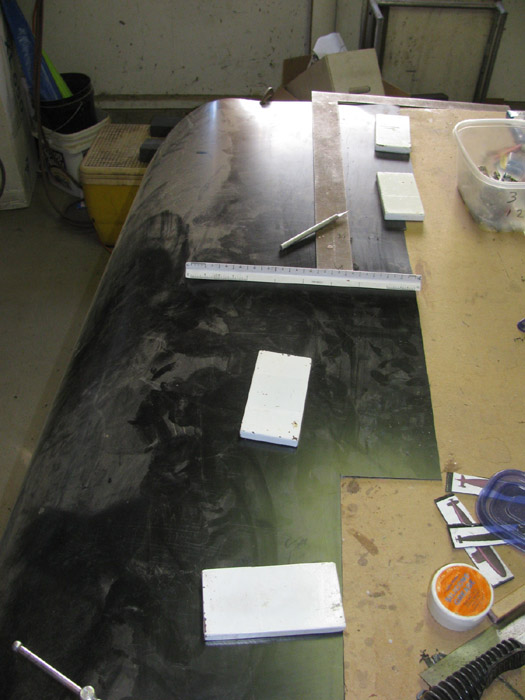

Ready to mark and cut sheet plastic.

Using the back side of the exacto knife, I drag the line next to the

steel ruler.

I make 5 or 6 drags across the plastic.

After scribing the plastic, I can bend it back and forth and it will

break on the line cleanly.

I scribe a line to the length I want the pieces to be.

I then use scissors to cut the pieces.

I could have made several passes with the exacto knife but the scissors

are faster for short cuts.

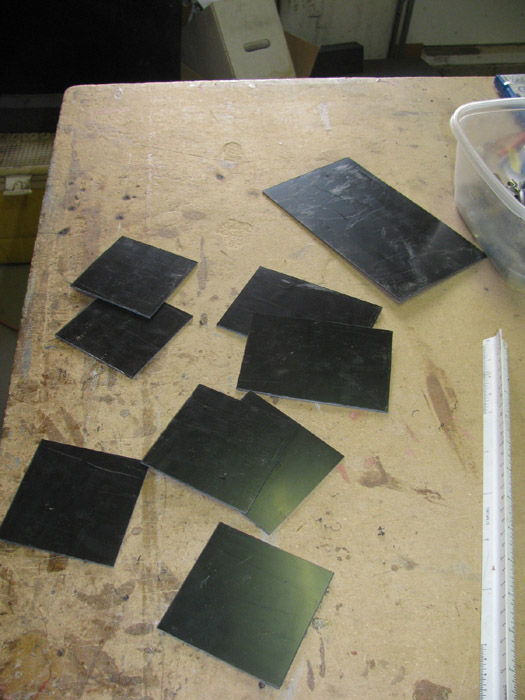

Using my steel ruler and exacto knife, I make center X marks by setting

the ruler across the center of the piece corner to corner.

Make two lines marking the center.

Then I use a sharp pointed tool (my 1/8" round file) to make a small

punch hole.

Using this small hole to hold the pointed end of my calipers, I make

2 circles on each piece.

The inside diameter and the outside diameter f the frame.

Before I can turn the pieces, I cut close to the outside diameter line,

making rough circles.

Time to get the bonding cement out.

I do not need to put glue in the centers as they will be cut out.

Using the inside diameter line, I put the glue all around the piece

up to and past the inside line.

I put 2 disks together and move on to 2 more disks.

I temporarily clamp them to the bench to keep them flat and tight together.

Once I have 4 disks made up of 2 disk, I can glue 2 to 2 make a 4 layer

disk. (1/4" thick)

Clamp it to the bench with a block.

Done the last 2 and clamp them to the bench.

The blocks happen to be my ballast blocks for the ALMA schooner and

are made of 1/2" thick steel plate.

Will let these cure over night.

======================

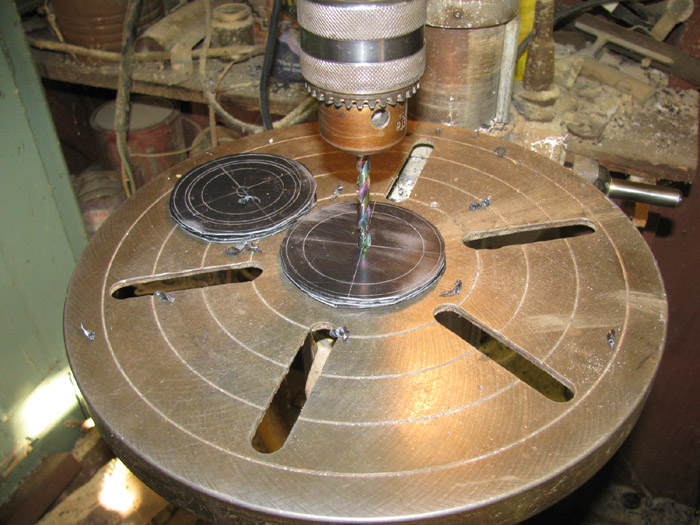

I will drill a small hole in the center using my center punch mark.

I will put the 2 disks on a long bolt and tighten up a couple of nuts

so they do not slip.

I will chuck them in to my drill press and using my home made cutting

tool, I will turn these pieces down to 3 1/8".

Starting the rough cut to make the disks round.

Cutting away, down tot he 3 1/8" line.

Once the 3 1/8" outside diameter is reached, I will use my exacto knife

and a tool made from a file cut out the indise to the 2 1/2" line.

Being cafe to not cut all the way through the first disk (4 layers)

all the way.

I haave cut the two disks.

I have sanded the inside diameter to the 2 1/2" mark.

I have sanded the knothces for the water and air passage.

I now have two completed circle frames 3 1/8" by 2 1/2".

Sides sanded and edges beveled.

|