The plan is to use the end caps as the housing

for the 0-ring seals and cup seal.

How do I plan to do this?

I need to make a cutter that will cut a hole with a flat bottom in the

PVC plastic that the end caps are made of.

I also need it on a 1/8" shaft so I can first drill the End Caps to

accept a 1/8" ID brass tube as a control rod bearing guide.

After a few attempts, I final have a simple design that works.

So, here we go.

I need a 1/8" shaft to put the cutter on. 1/8" brass rod will do nicely.

I need a piece of steel to make the cutter out of.

Tried hardened bolt but that did go well.

I abandoned that project.

Next I used a piece of flat bar steel., 5/8" square.

I drilled a hole in the center.

Started grinding on the piece to get it sort of round so I could put

it in the drill press to finish turning it in to a disk.

Again this did not go well.

There was a couple of other ideas that did even get started after thinking

through the work needed to accomplish the task.

Basically there was too much material to work down to get what I needed.

Today, I had a thought and went out to the shop and started in on it.

I took the flat bar and cut a 1/4" piece off.

Then drilled an 1/8" hole in the center of the edge.

With a new 1/8" drill bit, I was able to drill a hole that just barely

allowed the 1/8" brass rod start.

I actually had to tap the rod through the hole with a hammer, making

sure not to bend the rod.

I use no glues or soldiers on this tool.It's just a press fit.

That was not part of the plan but it just worked out that way.

Next I place the rod and blank cutter in the drill press.

I measured each end because I could see that I had not gotten the hole

in the center.

So, I ground down one end until it was close to the same length on

both sides of the rod.

I put my flat bar with several different sized holes on the press table

and clamped it down with the correct hole to hold the rod end.

With the drill press running and using my Dremel, I slowly ground the

ends of the metal piece down.

I would stop often to measure the width.

I wanted to stop before I got the cuter too small for the seal.

Well, I was making the large cutter for the cup seal, first but ended

up making it the small cutter because...I did over grind the piece.

With calipers in hand, I continued grinding very slowly until I got

the size I wanted for the O-ring.

My goal was to make the hole small enough to allow the o-ring to be

put

in the hole with slight compression on the outside.

The Dremel is sitting on the press table and held down my hand.

The wheel is big enough that it cut the full end at one time as the

piece was spinning.

Once I got the piece to the correct width, I hand filed the cutter edge.

Just a little back cutting, not much needed.

Look closely and you can see the step at the center where the rod is.

1/8" o-ring for size comparison.

I have a cutter....Time to test it.

First, I drilled an 1/8" hole in the PVC cap as the guide for the cutter

shaft end.

This will be brass on the real caps.

The tubing will be recessed so the cutter only cuts plastic but the

control rods will go through brass guides.

Cutter doing it's job.

Here's the hole the cutter made.

O-ring inserted in the hole.

1/8" brass shaft going through o-ring seal.

On to the larger cutter for the Cup seal.

Here's the cutter and the hole.

The seal has a tappered side.

When the seal is placed in the hole the sides will be compressed until

it is almost as small as the small end of the cup seal.

Seal is sitting there as well.

Notice I put both cutters on the same shaft.

Why, because it's harder to loose larger tools in the shop.

1/8" brass rod going through the cup seal.

I now have a tool to cut holes for the seals I use in PVC.

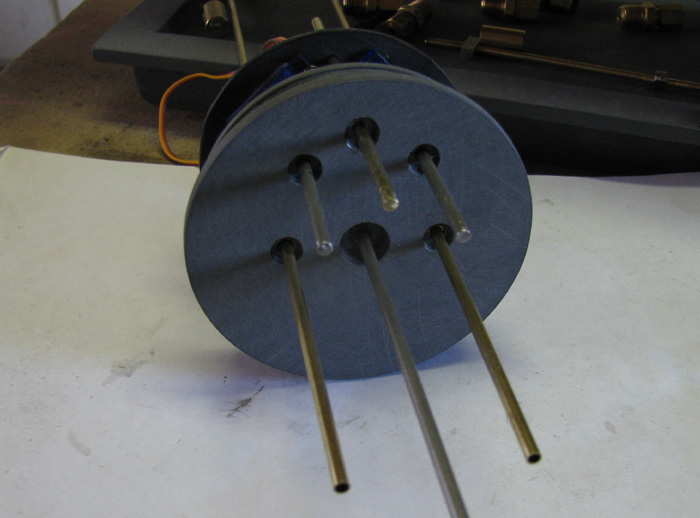

End cap with (less cup seal and o-rings)

propeller shaft

Two mast Gizmo shafts

Rudder and rear planes rods

And Sail plane rod

|

Side view

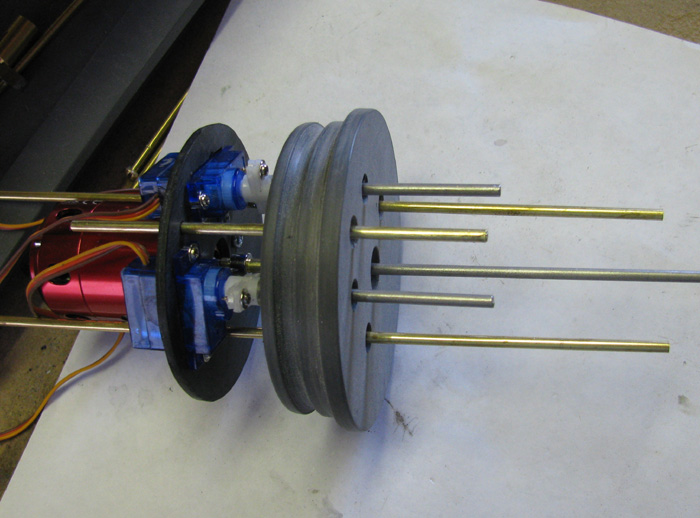

The Mast Gizmo servos in place.

These are continuous rotation either direction. Proportional. |

Control rods and shafts from top down.

Mast Gizmo #1

Real Planes

Sail Planes (this will be top center)

Propeller shaft

Mast Gizmo #2

Rudders |