Now that my Akula II and Skipjack have reached a point that they run

really well and at most need some fine trimming,

I found my self with nothing to.

Well there is the ALMA but that's painting and the weather has now

turned cold. (Did I mention I hate painting)

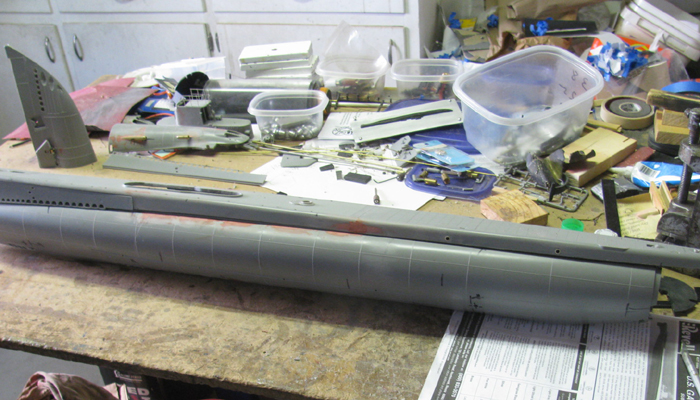

Last Sunday I was going back and forth to the shop where I also do my

laundry.

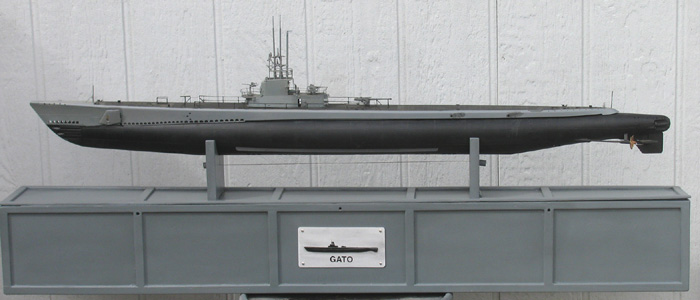

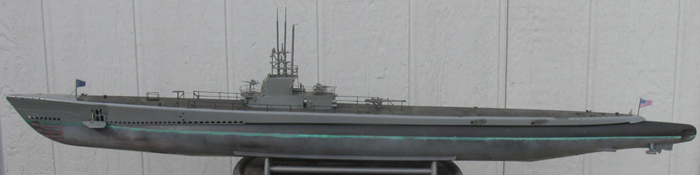

I keep looking at the Type VII and Gato sitting on my back wind porch.

I like the looks of the WWII boats but looked in to the history and

various changes between boats.

I can not tell one from another unless I have photos side by side.

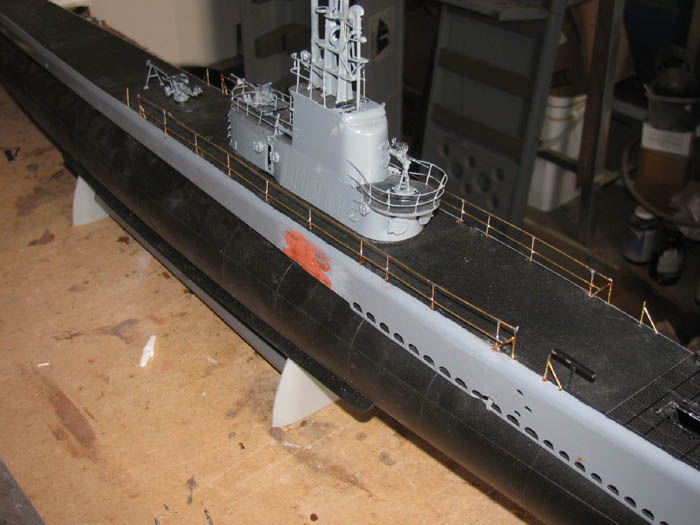

So I decided to drag the Gato out and work on it.

Why? I just bought some wtc tubing to do a complete rebuild of the

George Washington wtc

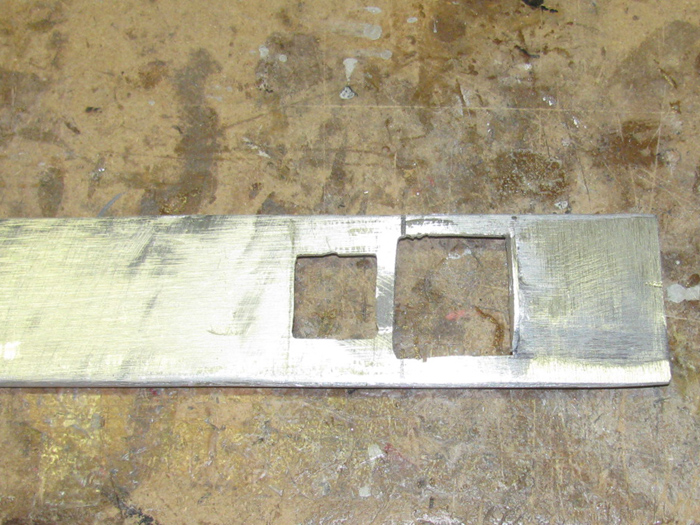

Turns out the tube is 2.5" in diameter and that just happens to be

the diameter for the Gato.

So I got enough to do both.

I do not plan to modify the looks of the kit boat but there are some

thing I will leave off so this can be RC.

There are so many small fragile parts that would not last long going

through the weeds at the pond.

One more thing to point out.

I will probably bounds around from one thing to another.

==========

It starts. - November 20th =================================================

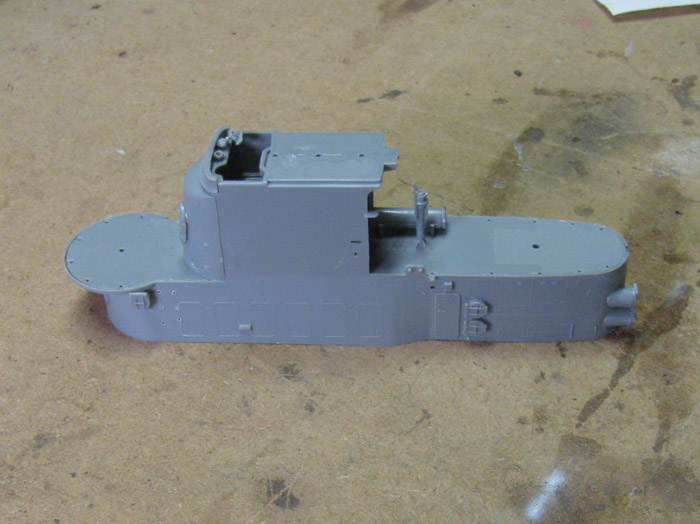

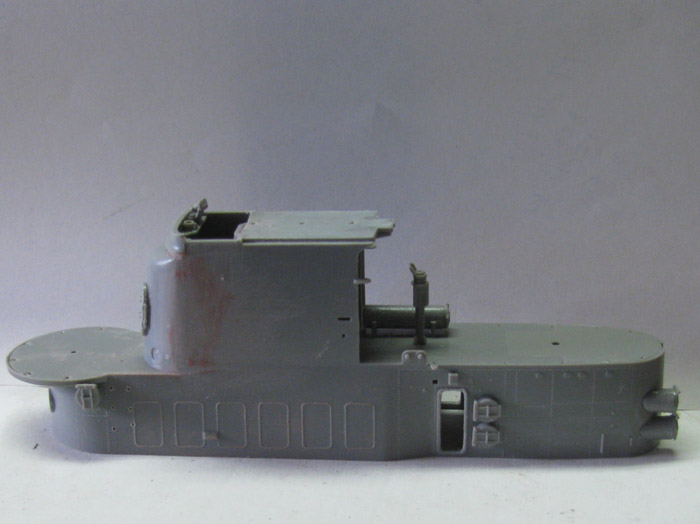

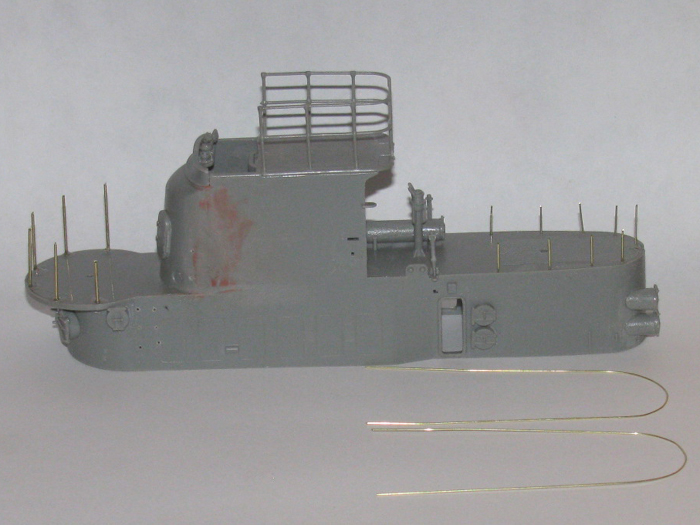

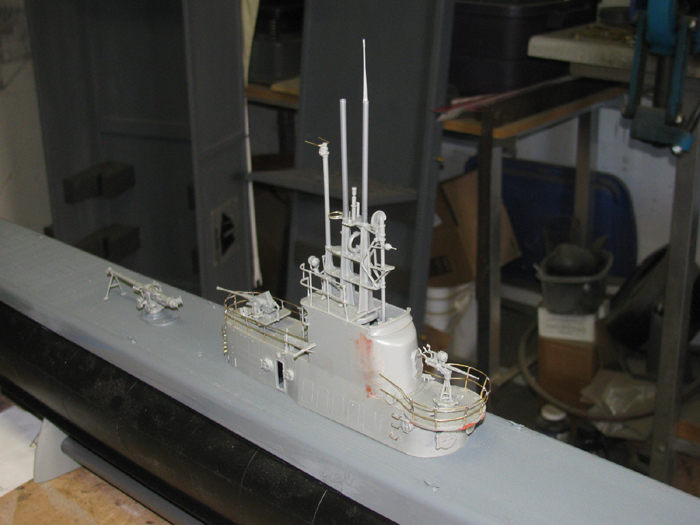

I forgot to take a photo of the conning tower before I assemble the

lower section.

I would have liked to cut the two side doors out but with the conning

tower sided already glued together, I am not sure I want to cut in to it

now.

We will see.

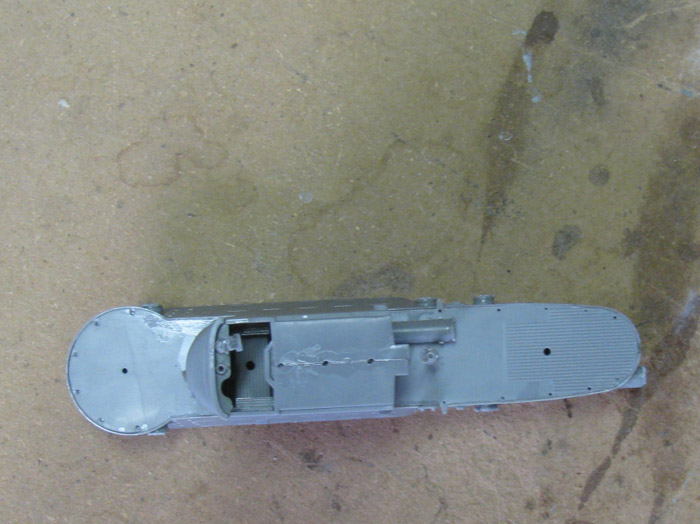

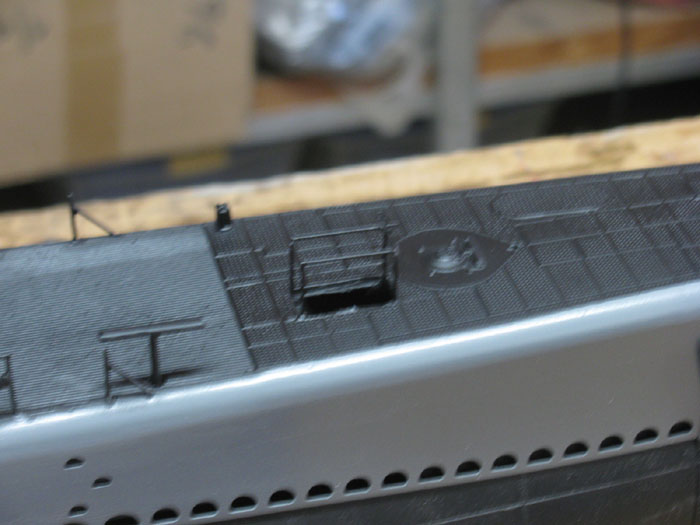

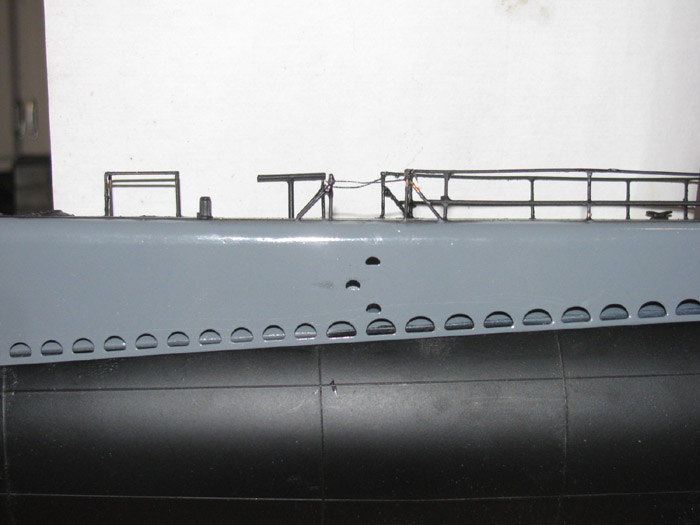

Top of conning tower.

I have drill two 1/4" holes in the floor of the bridge to let air out.

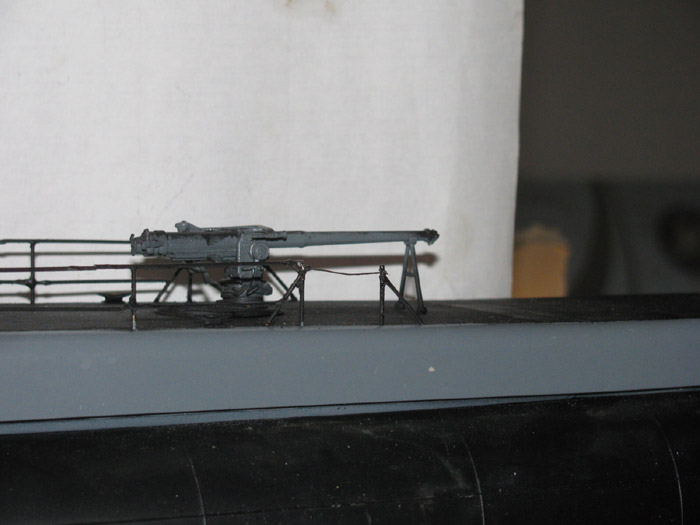

4" gun assembled.

The gun is not installed to the deck mount yet.

November 22th =================================================

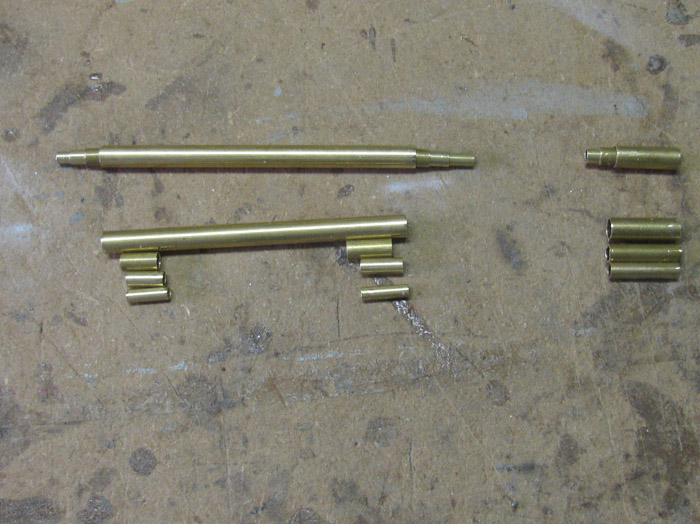

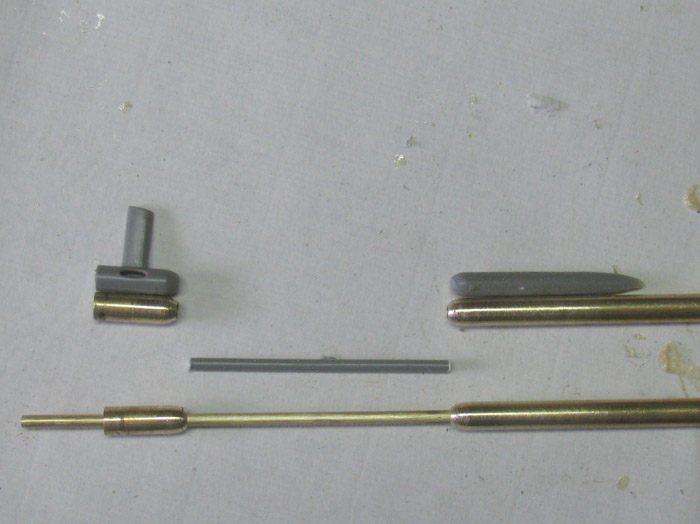

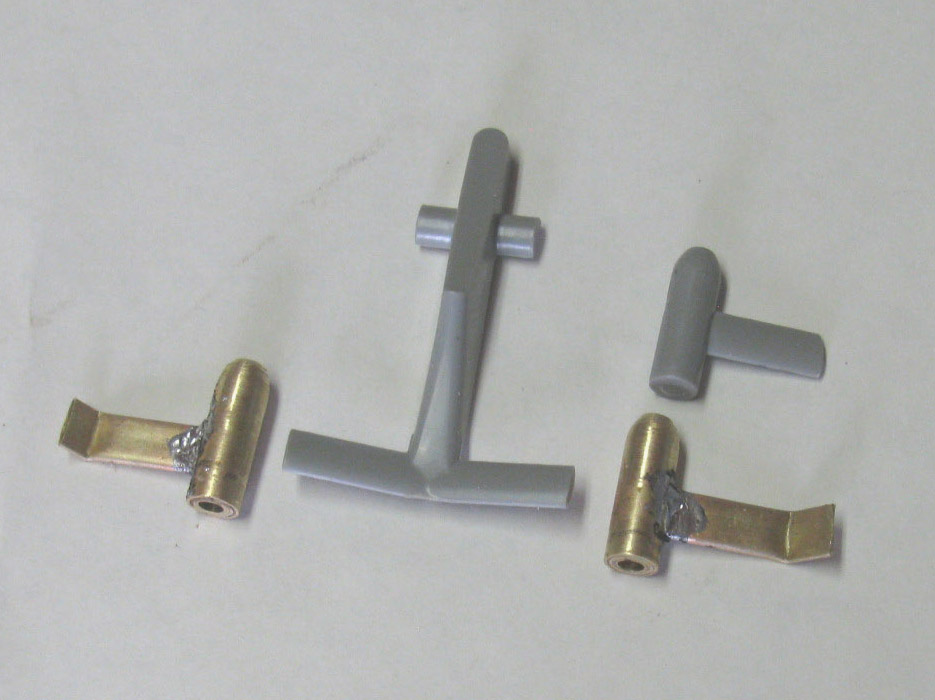

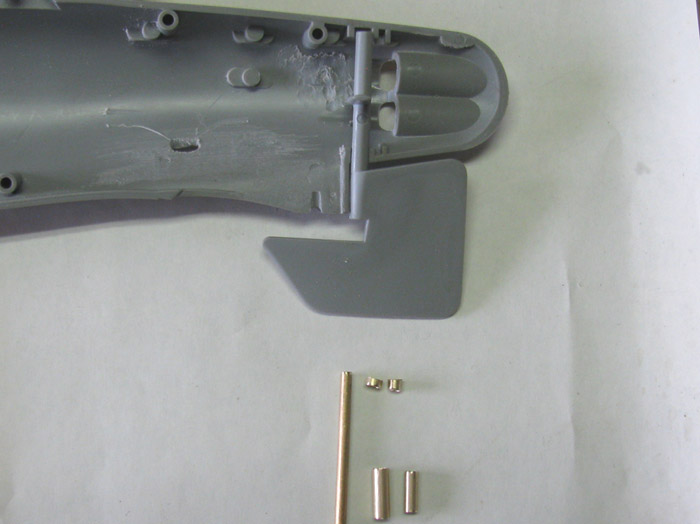

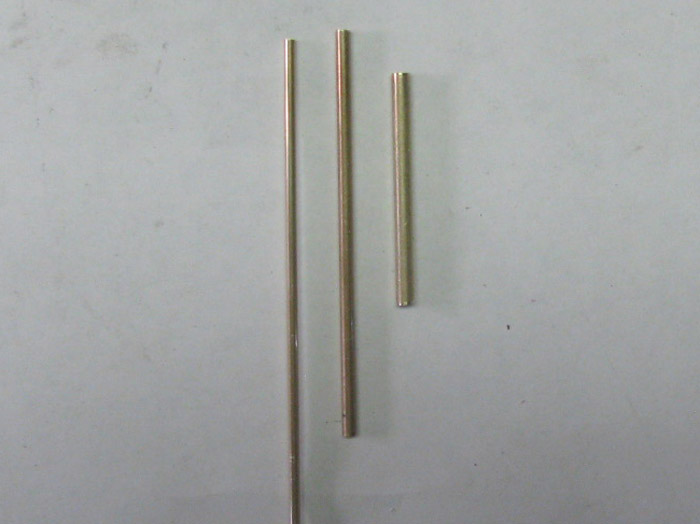

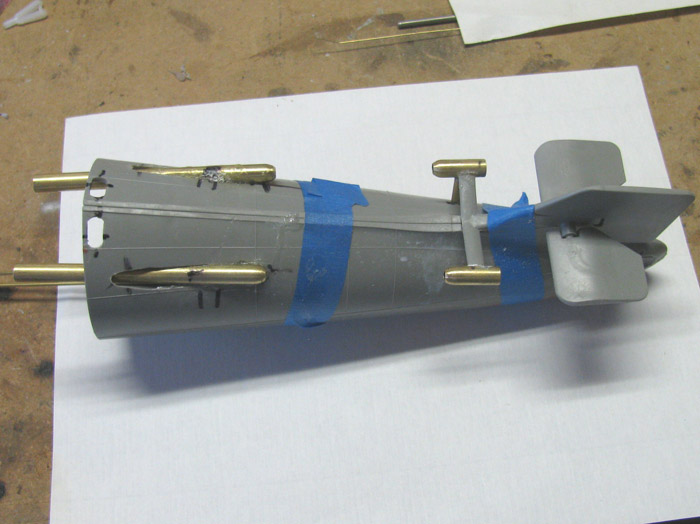

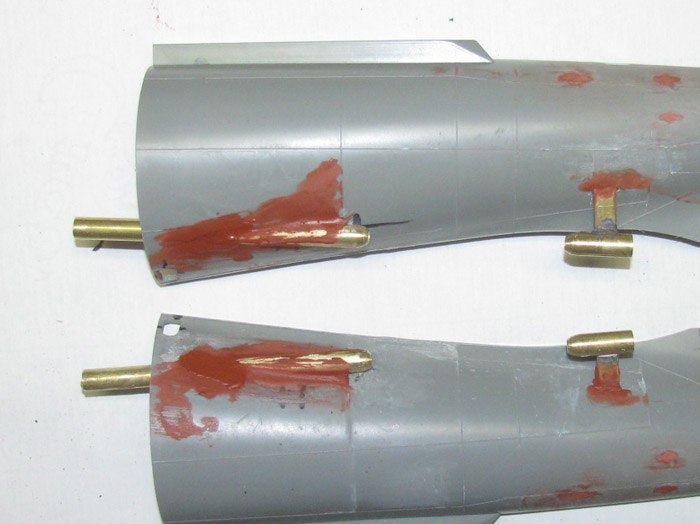

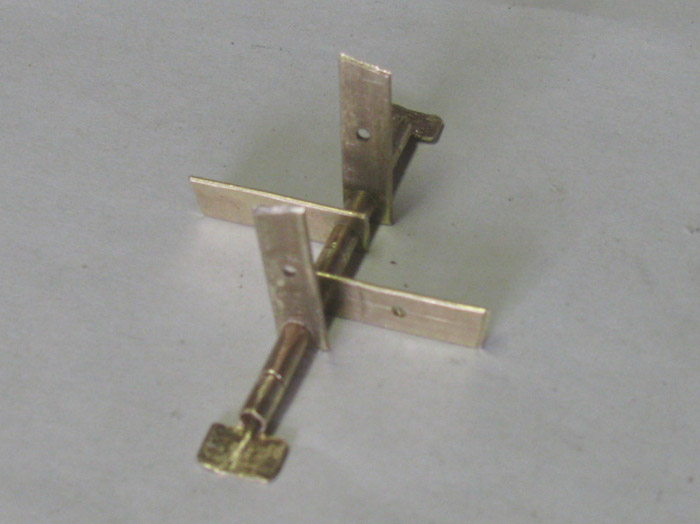

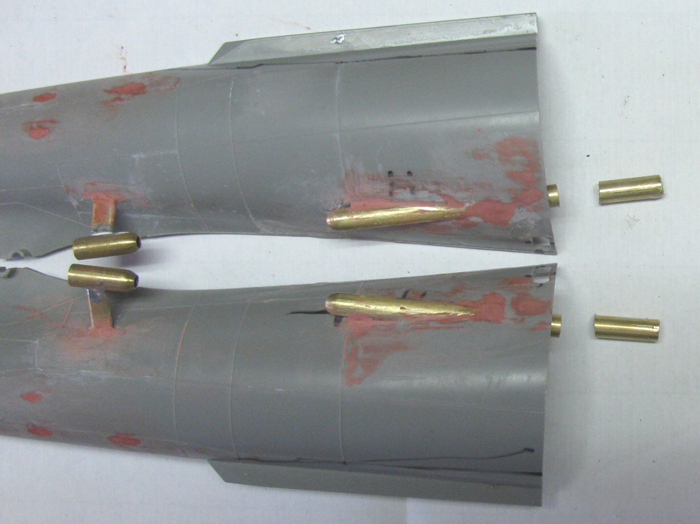

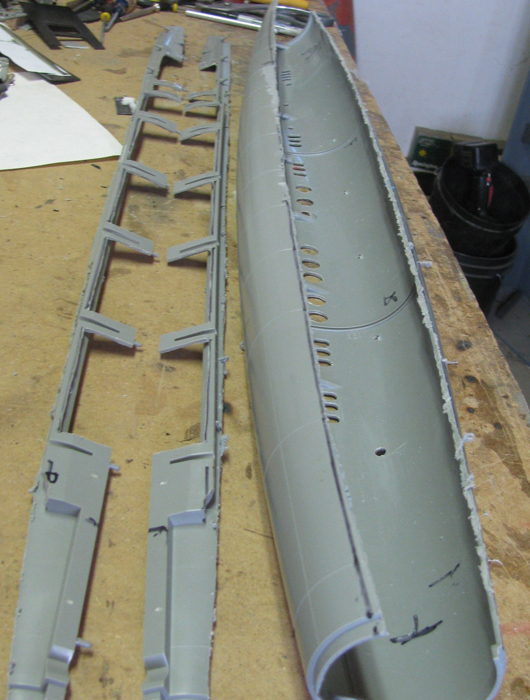

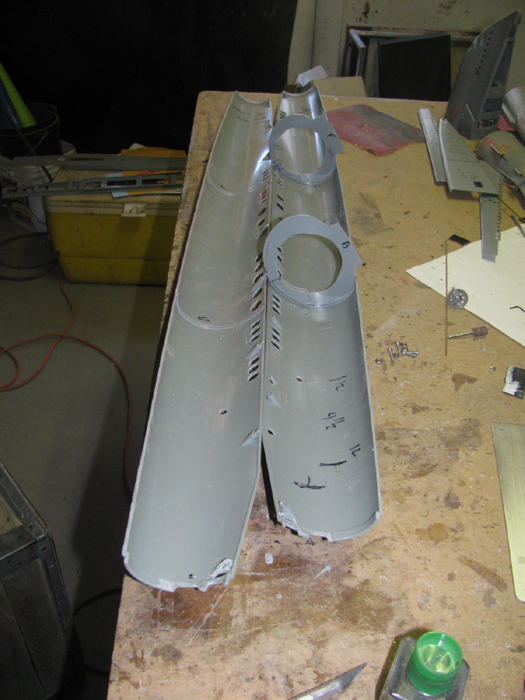

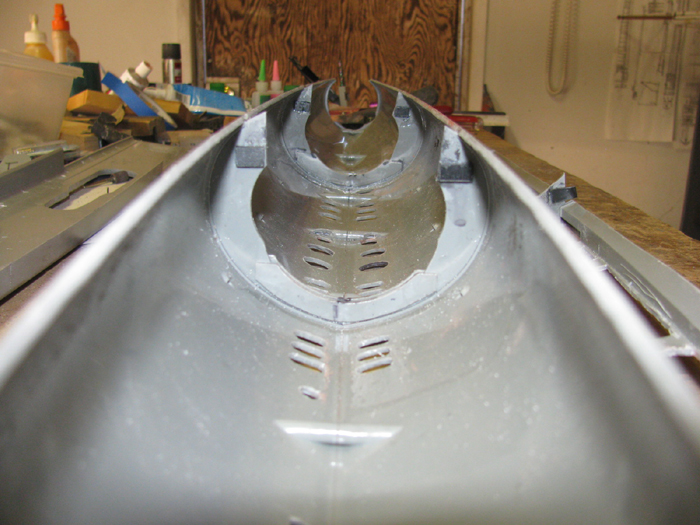

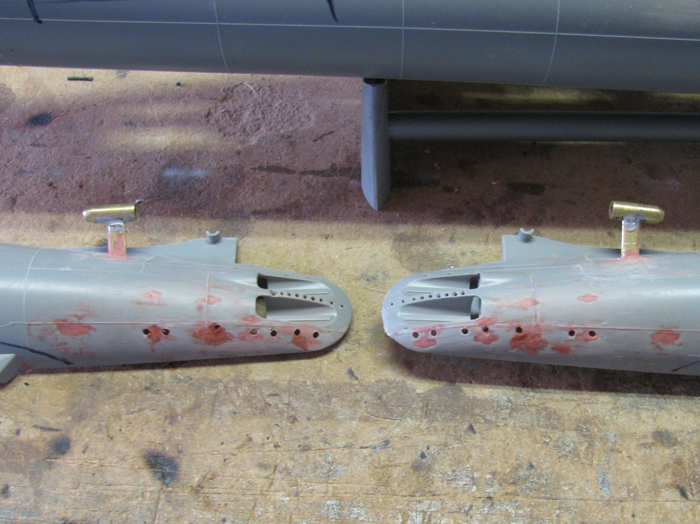

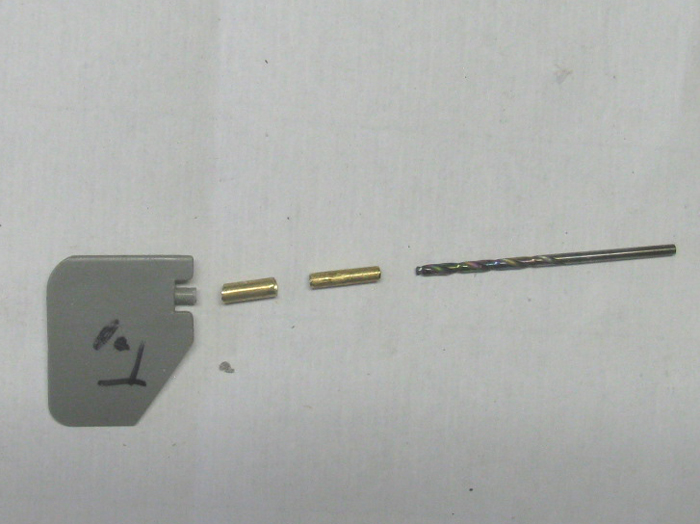

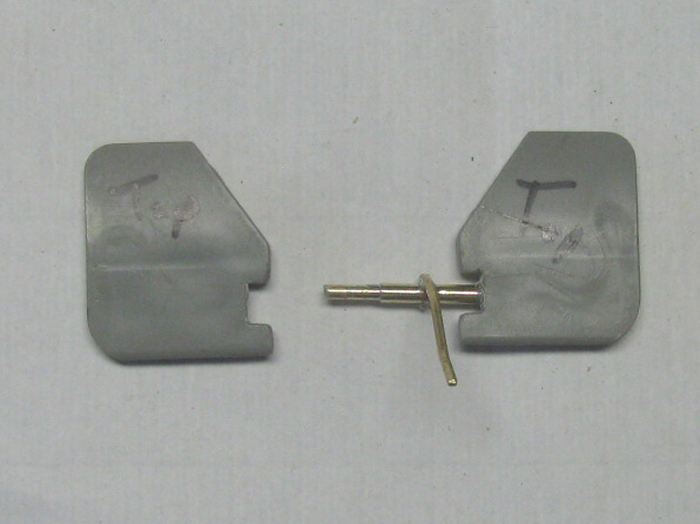

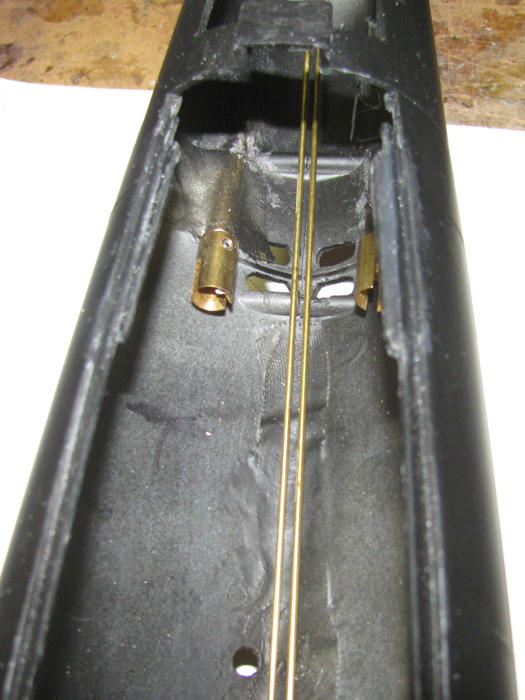

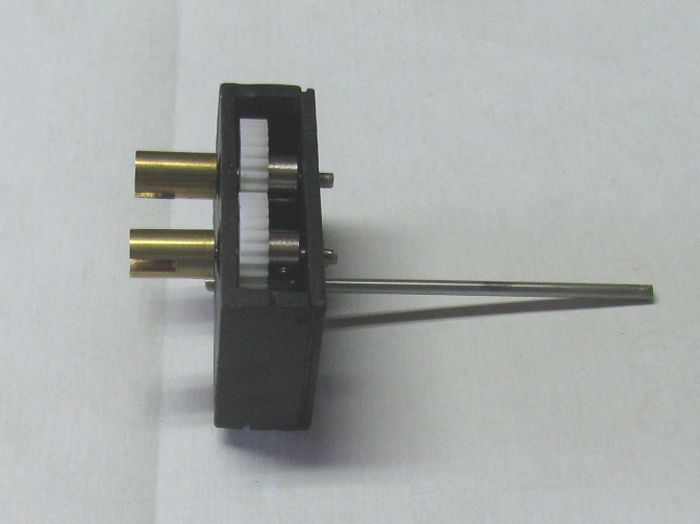

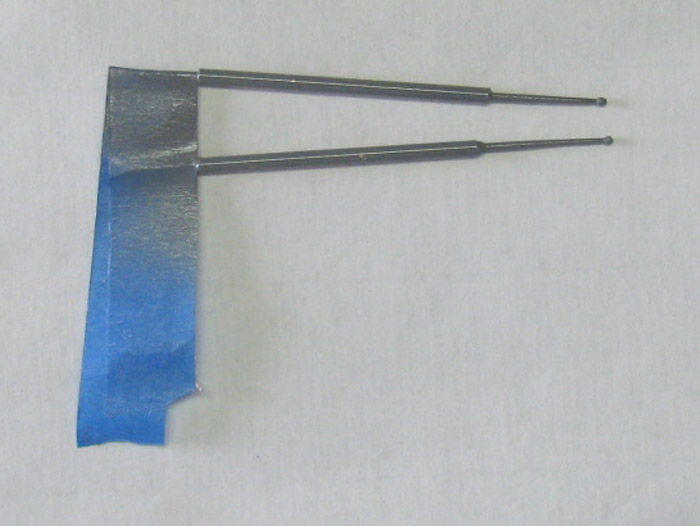

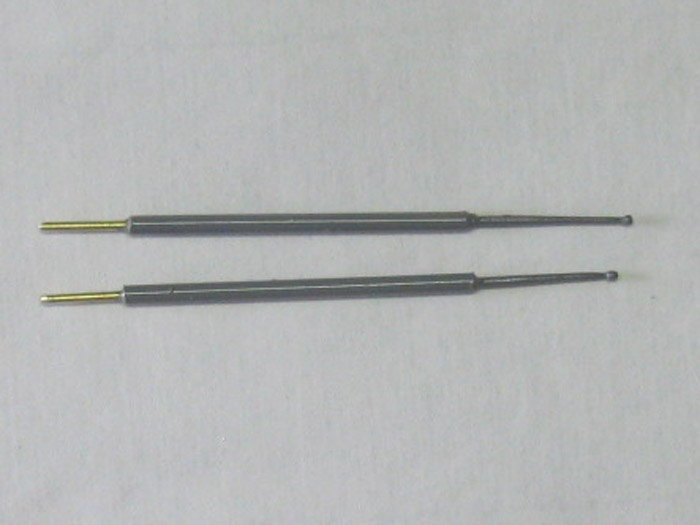

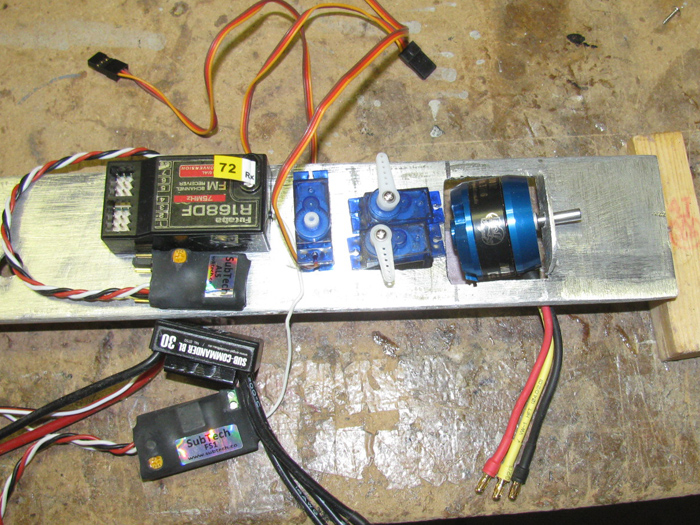

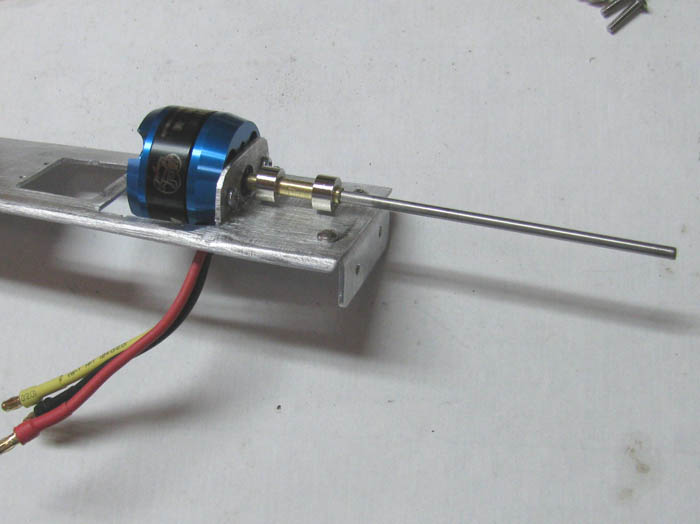

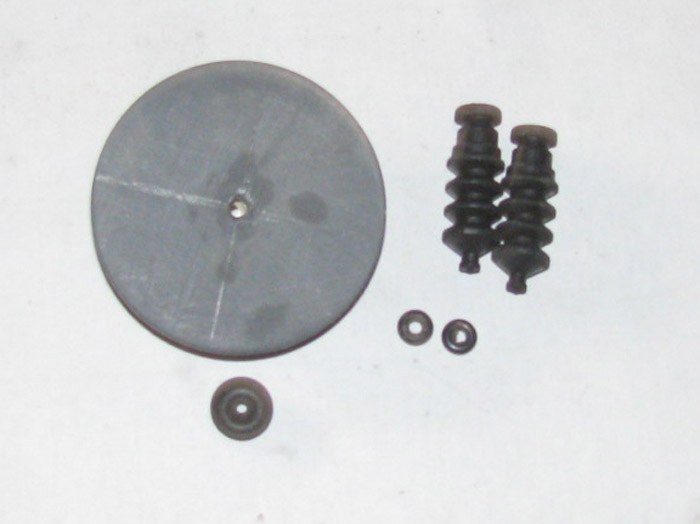

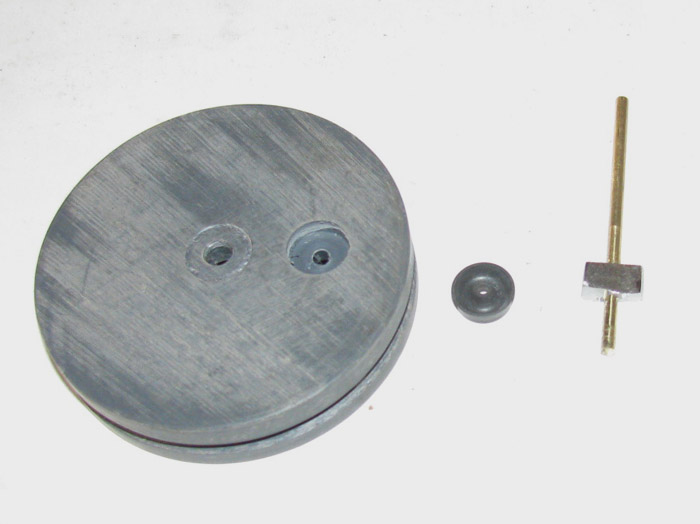

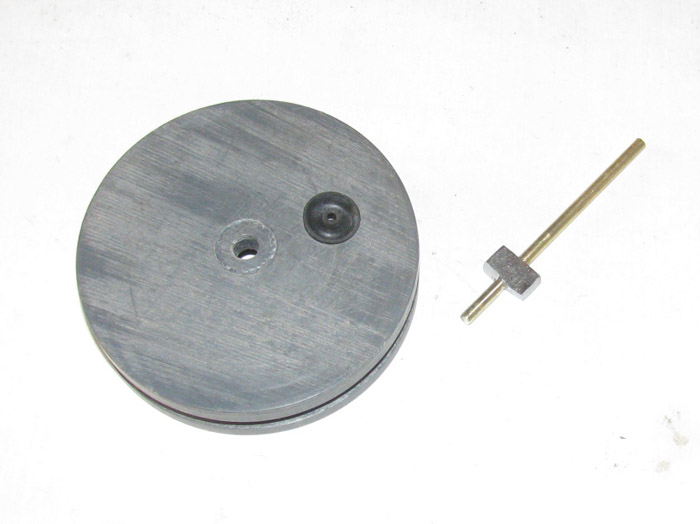

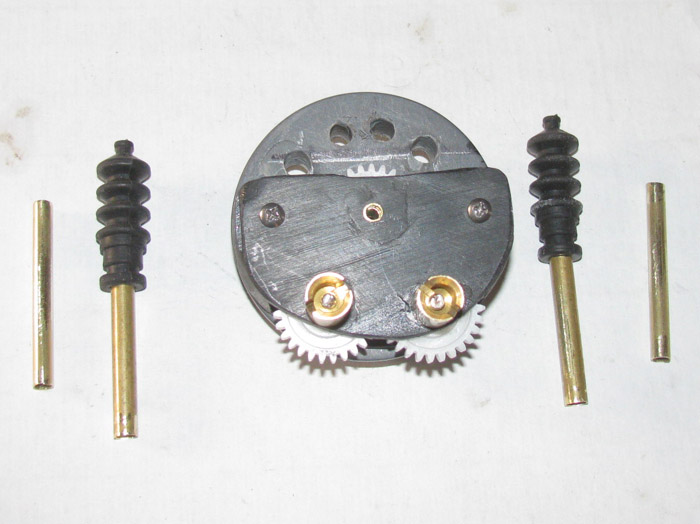

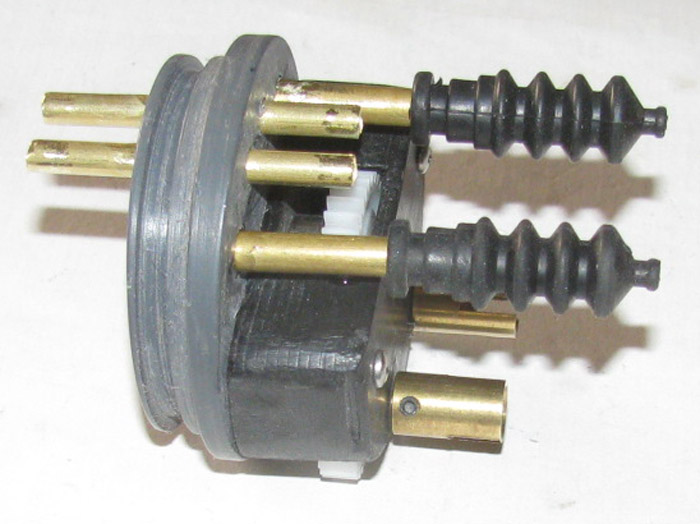

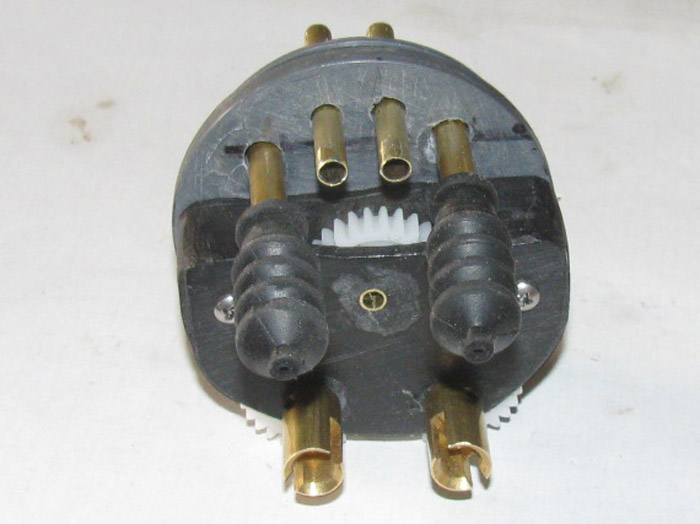

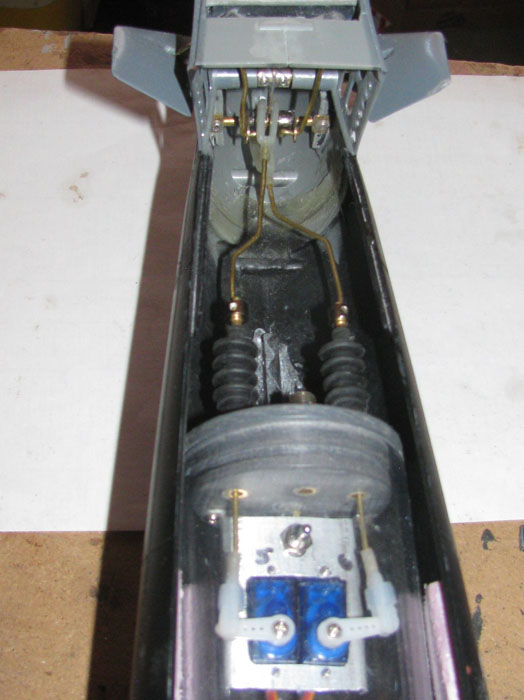

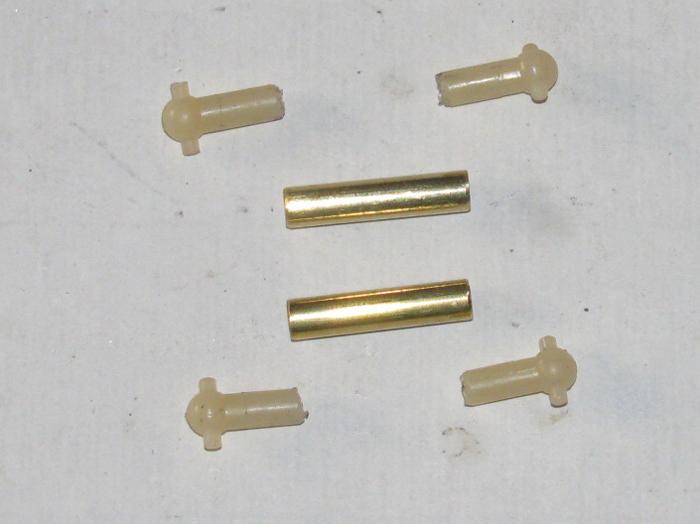

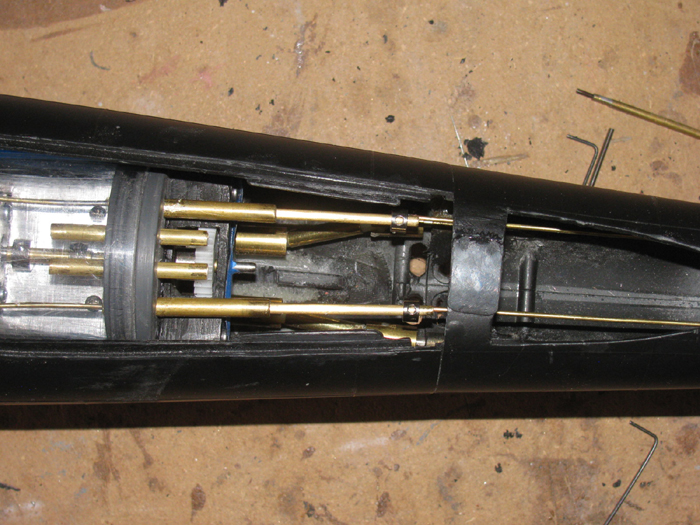

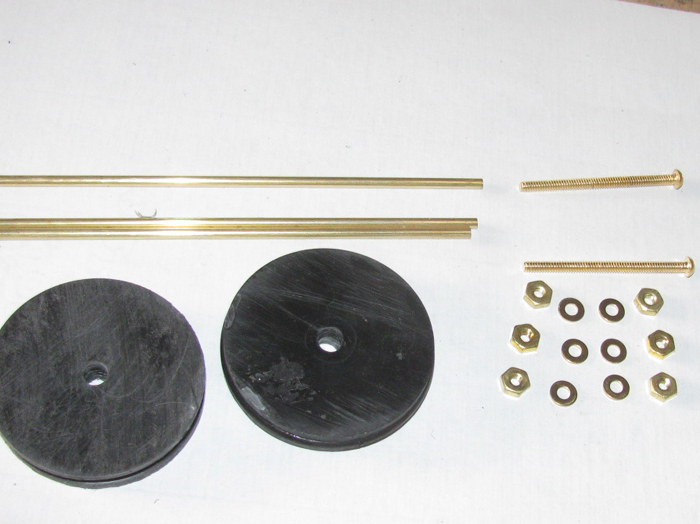

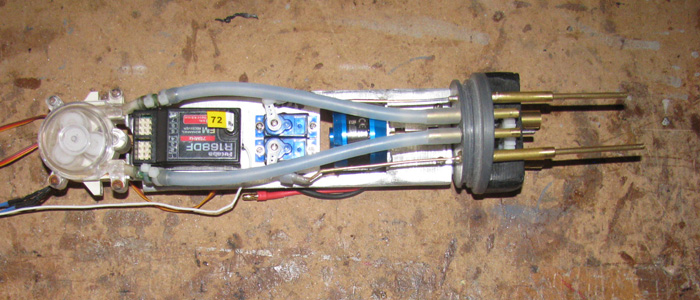

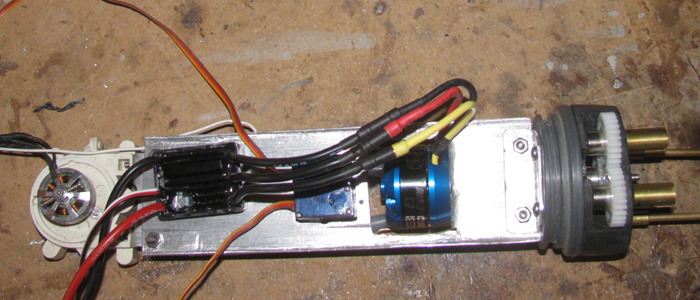

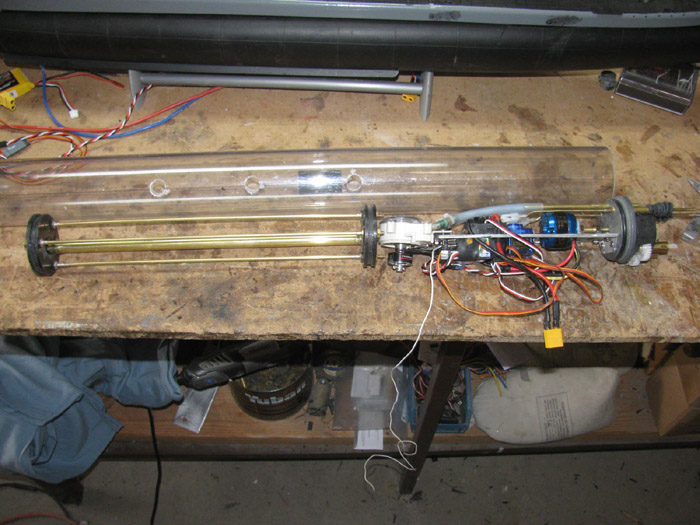

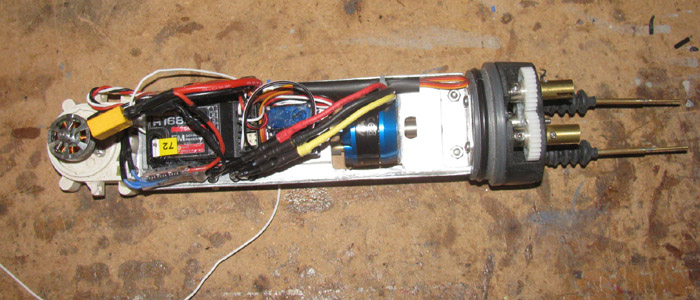

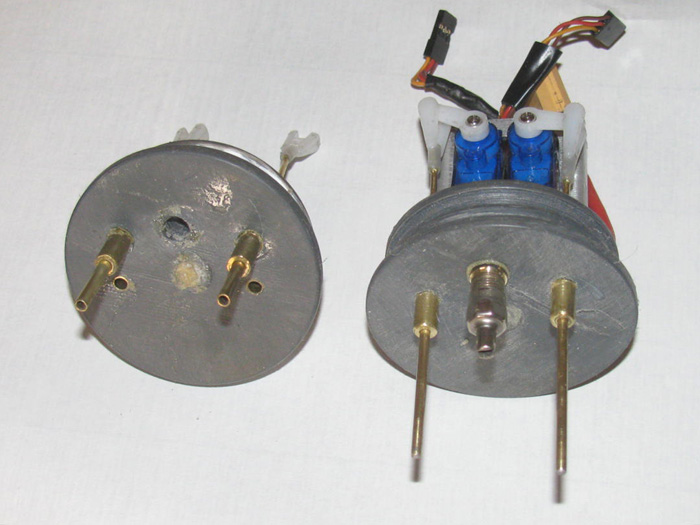

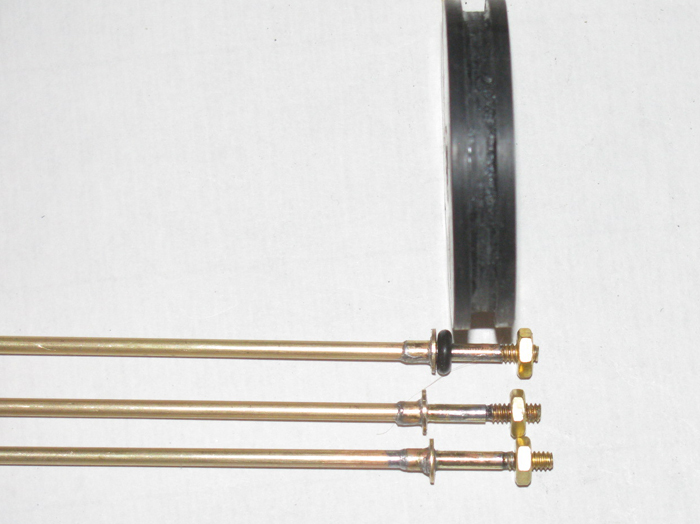

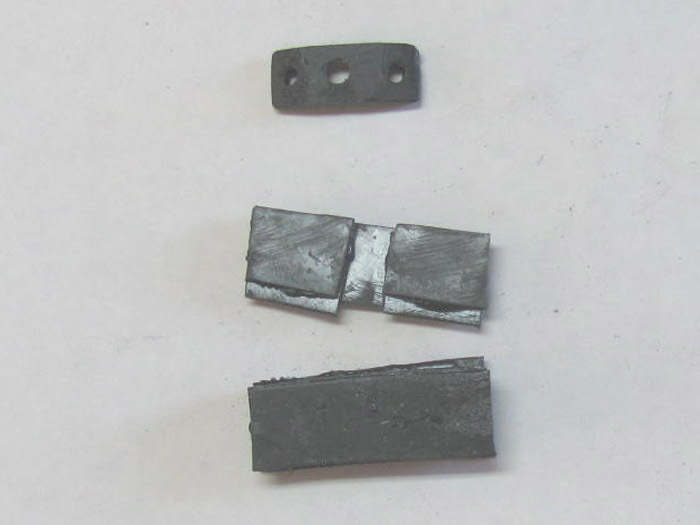

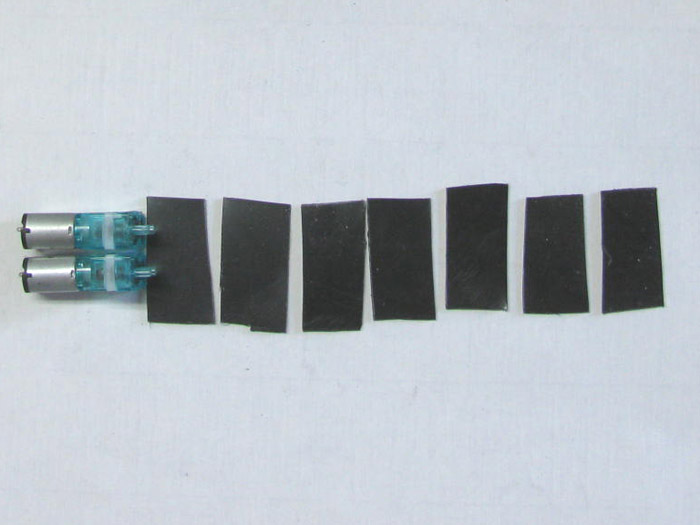

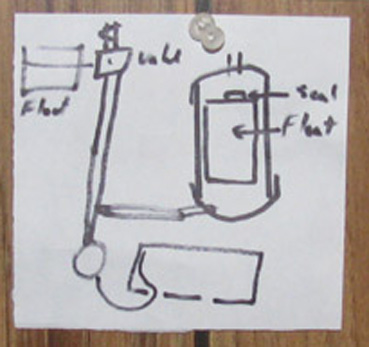

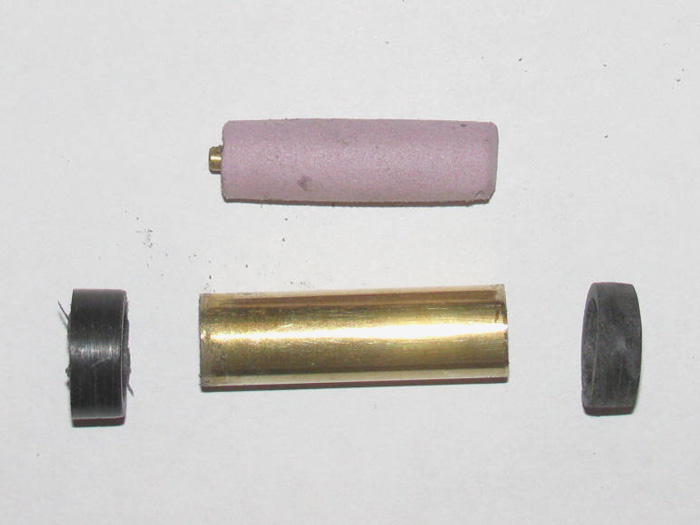

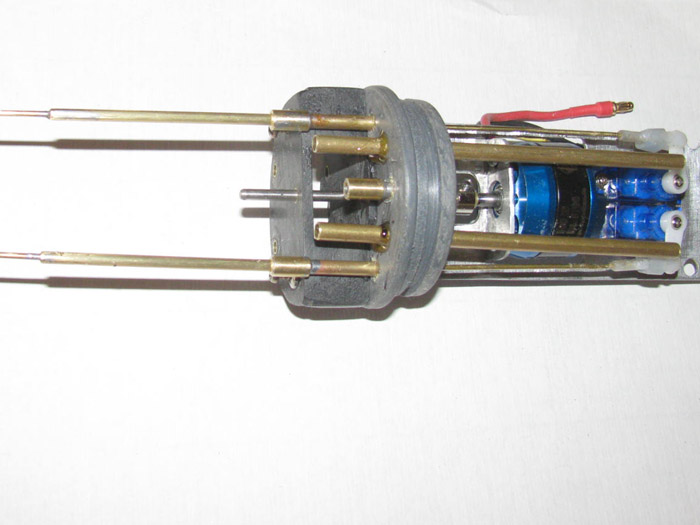

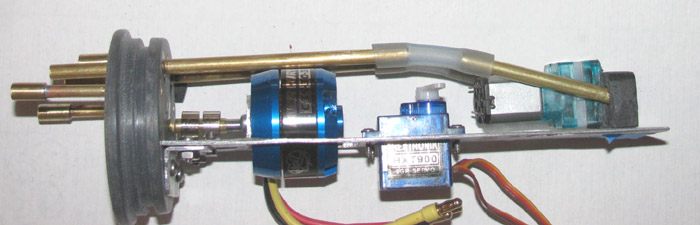

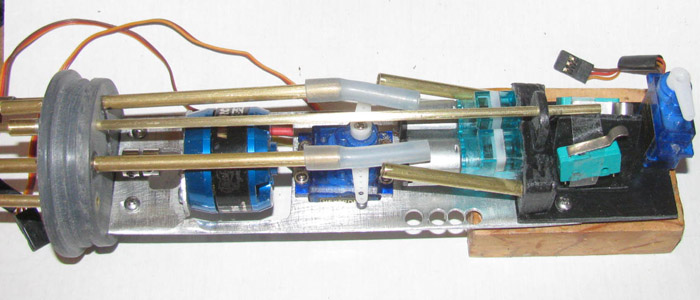

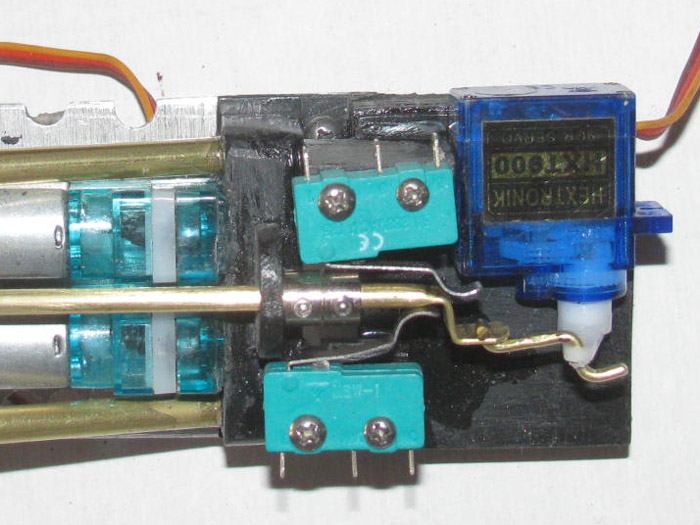

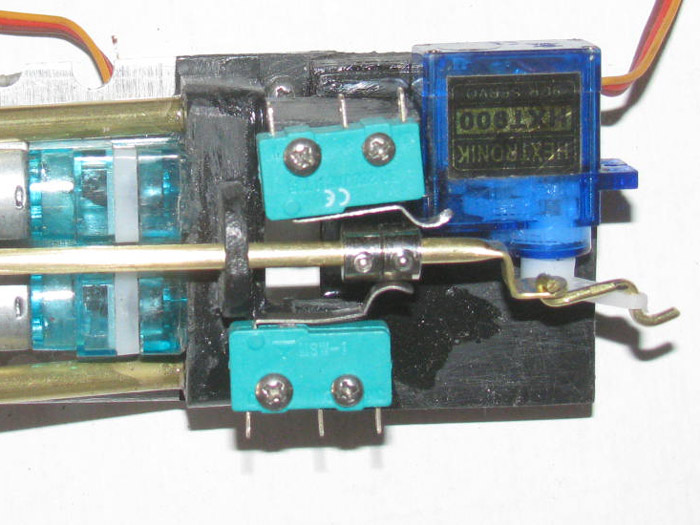

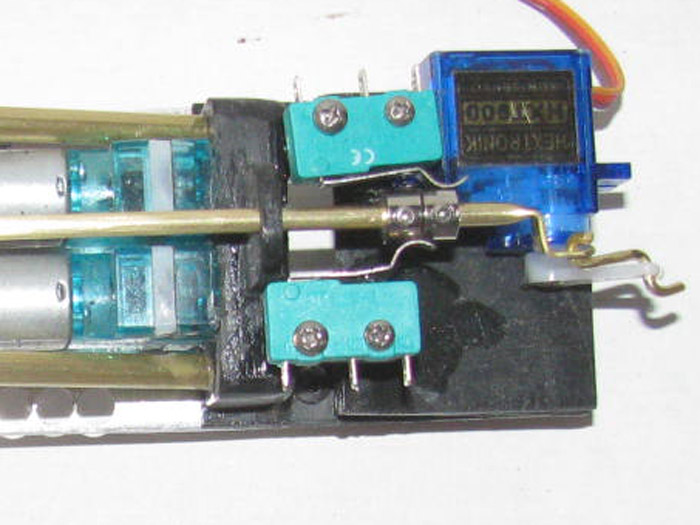

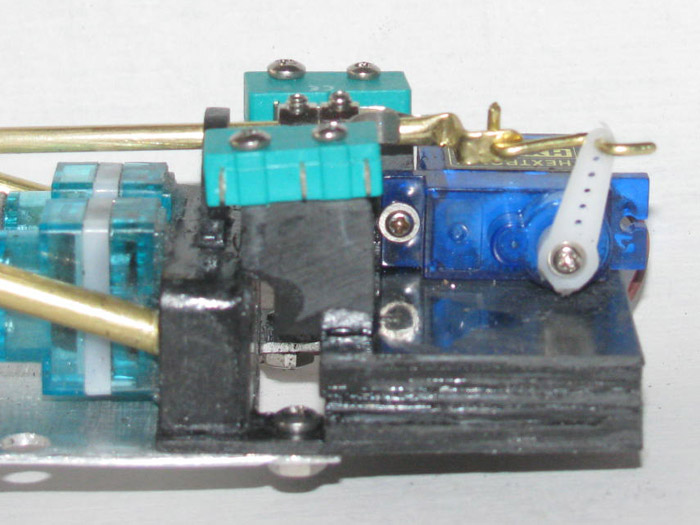

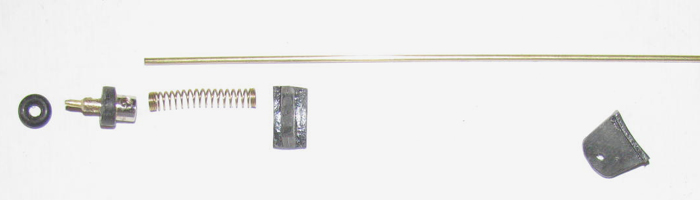

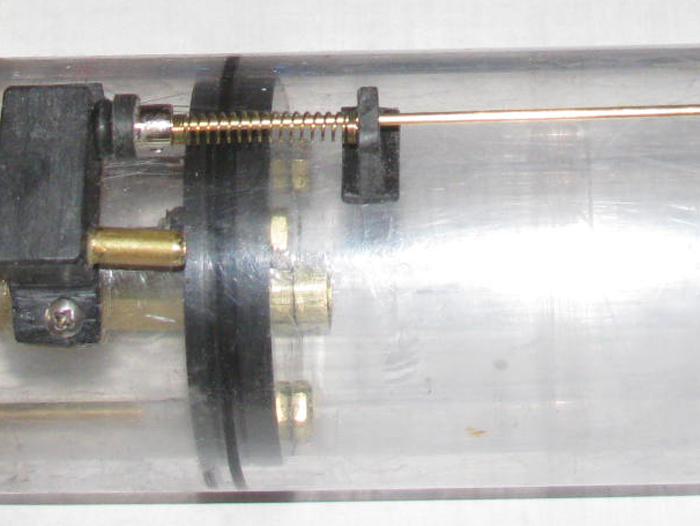

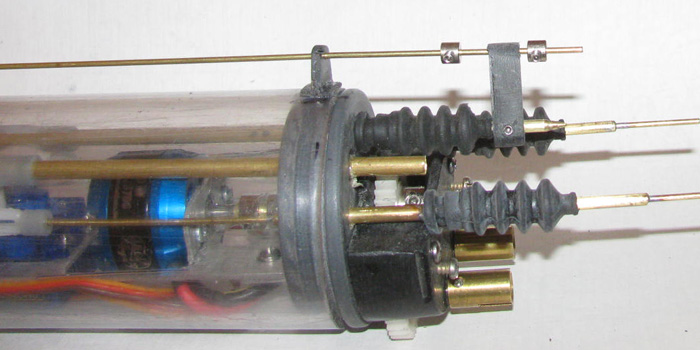

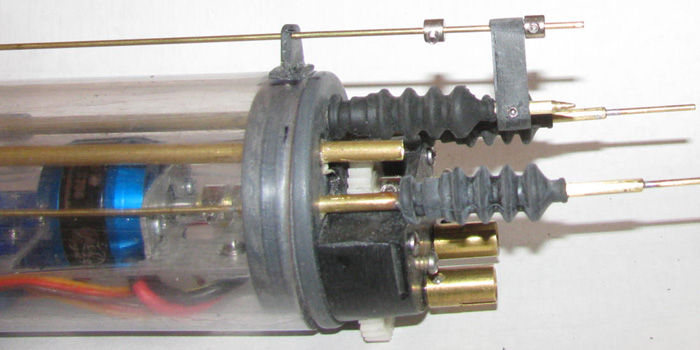

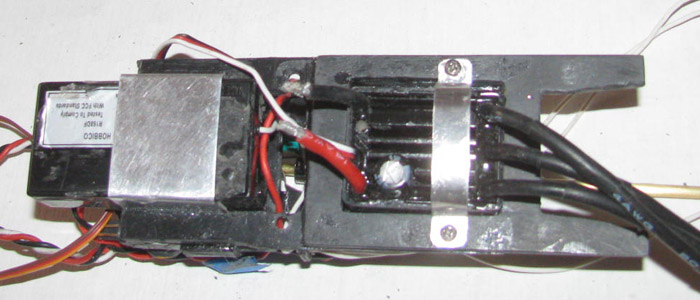

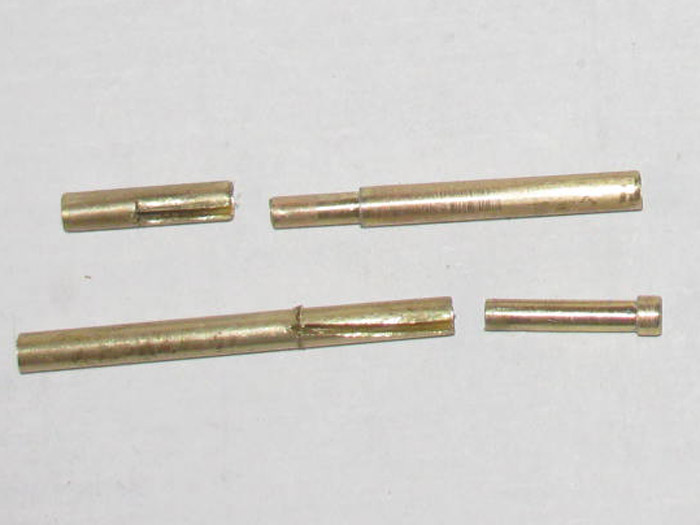

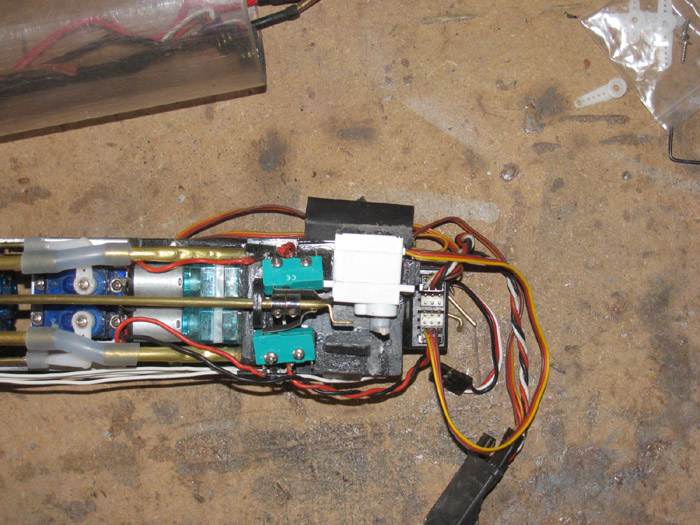

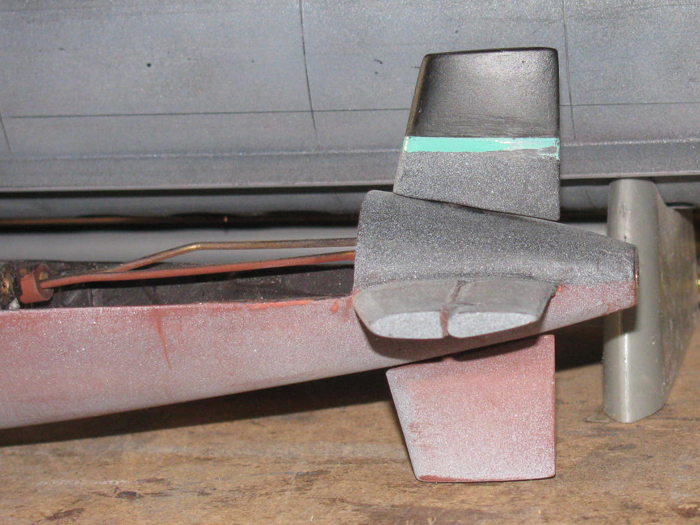

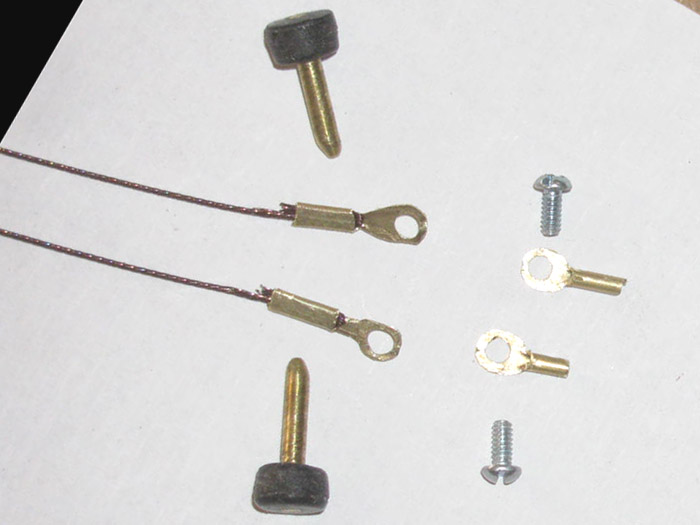

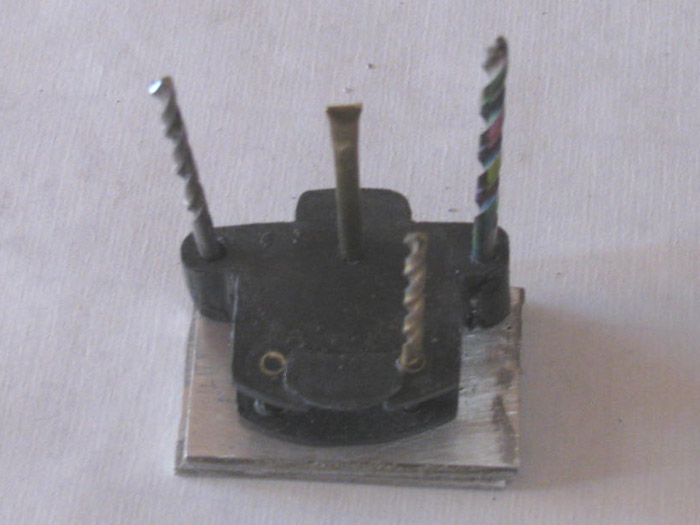

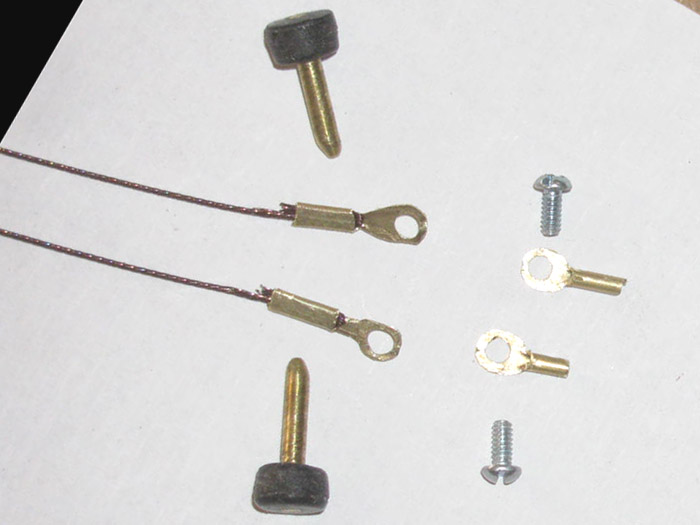

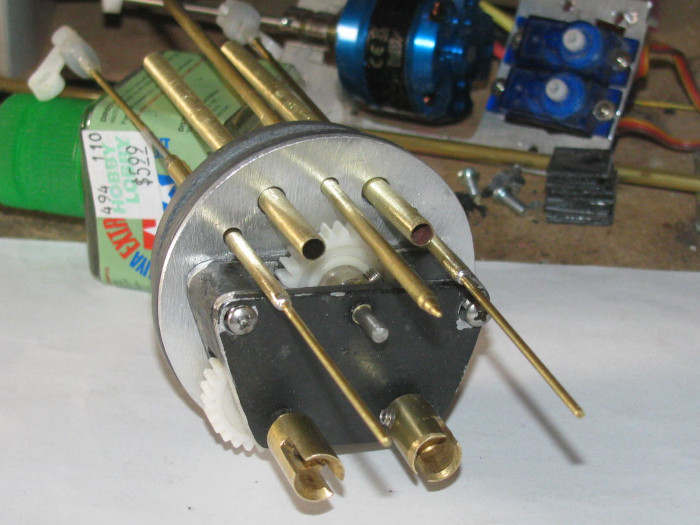

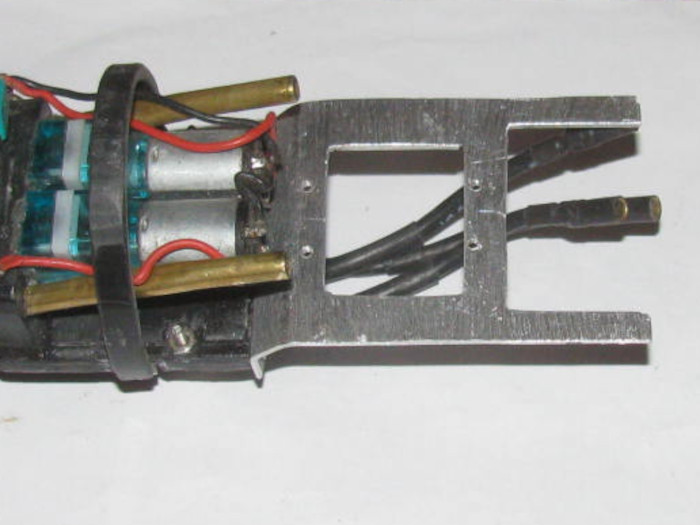

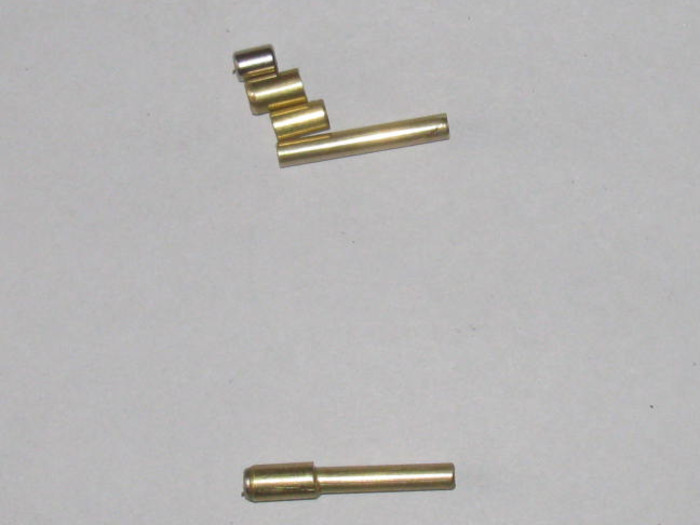

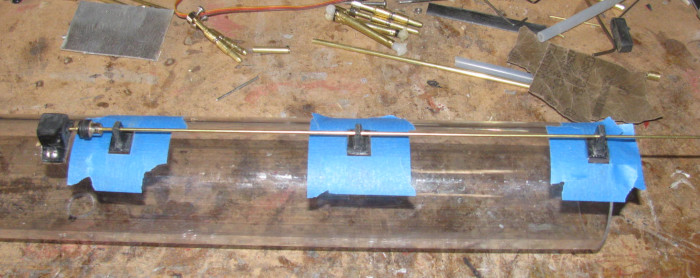

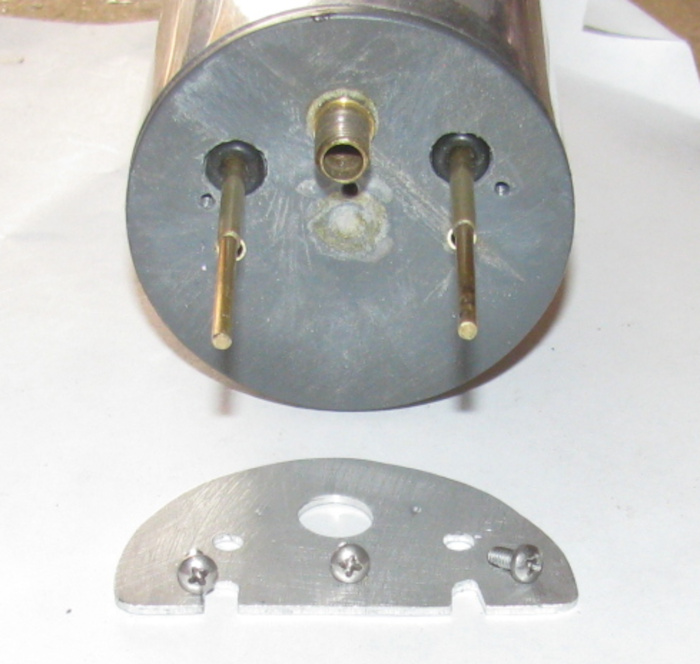

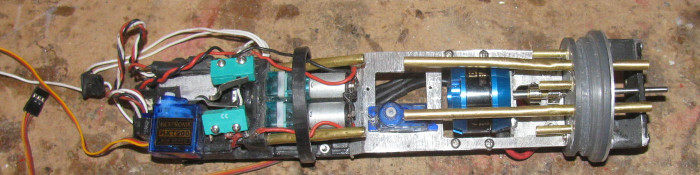

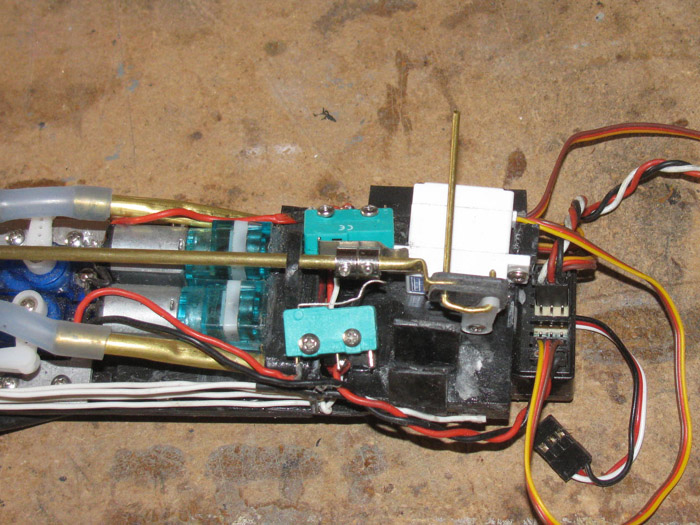

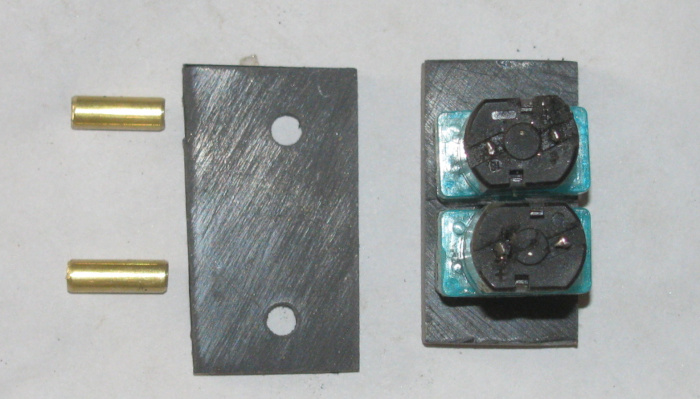

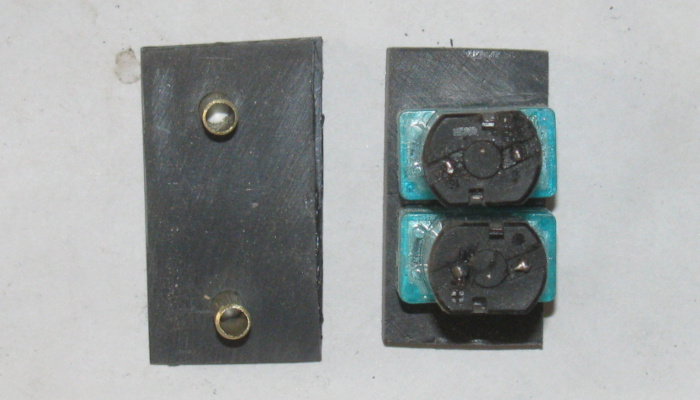

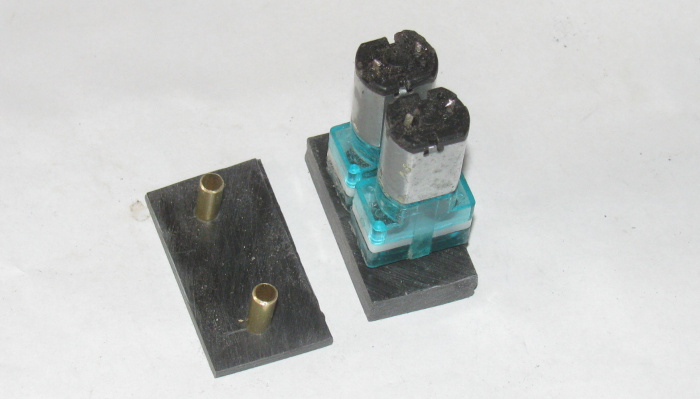

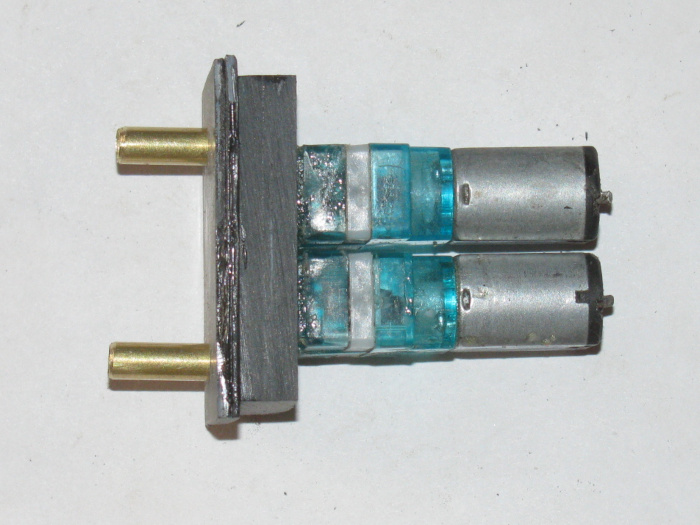

What you are looking at are the parts to make the propeller through

hull tubes and the back support struts.

All those short pieces of brass are to size the outside tubes down

to accept the 1/8" propeller shafts.

On the right is the through hull tube with the short pieces being the

shaft bearings.

I will shorten them so they are the same length before in stalling

in to the long tubes.

I will use a length of propeller shaft to align the bears as they cure.

The parts on the right are the rear support struts.

The will be shorten to match the original plastic parts and one end

will be shaped and the other flat.

Those parts are no assemble yet.

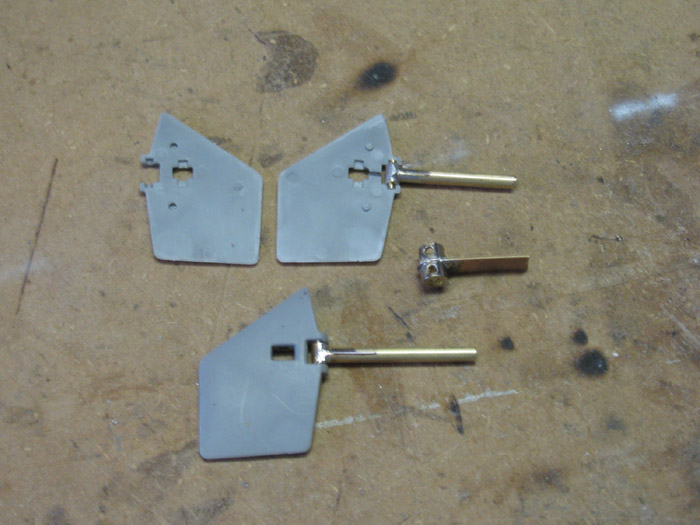

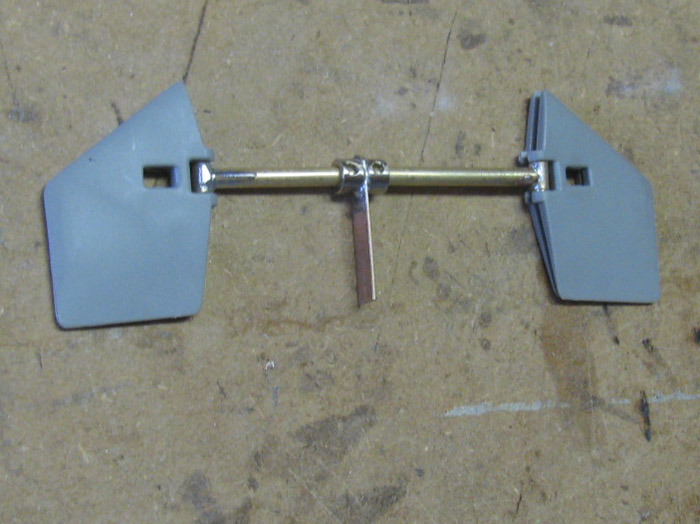

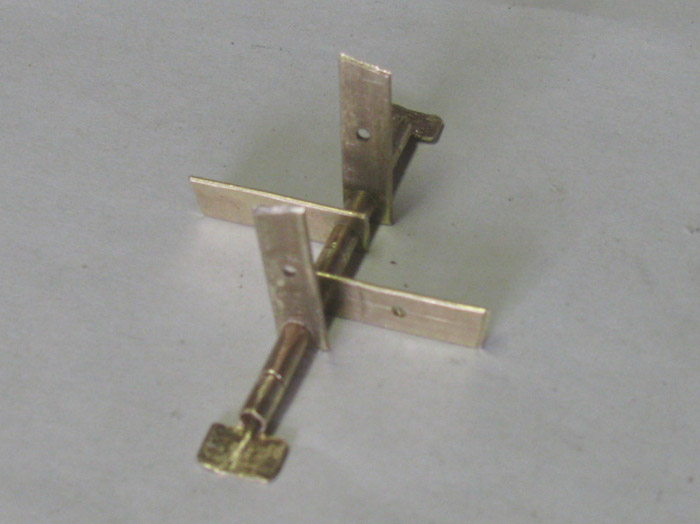

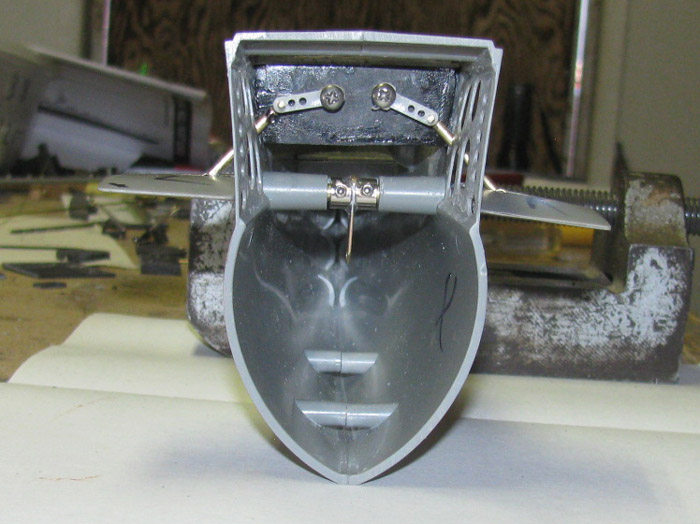

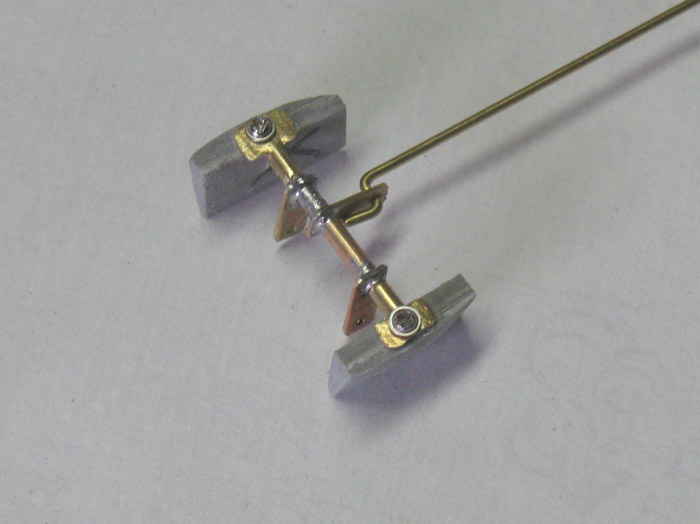

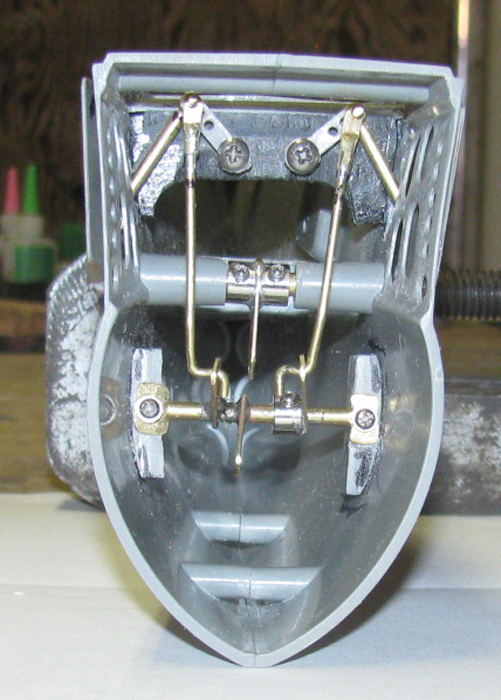

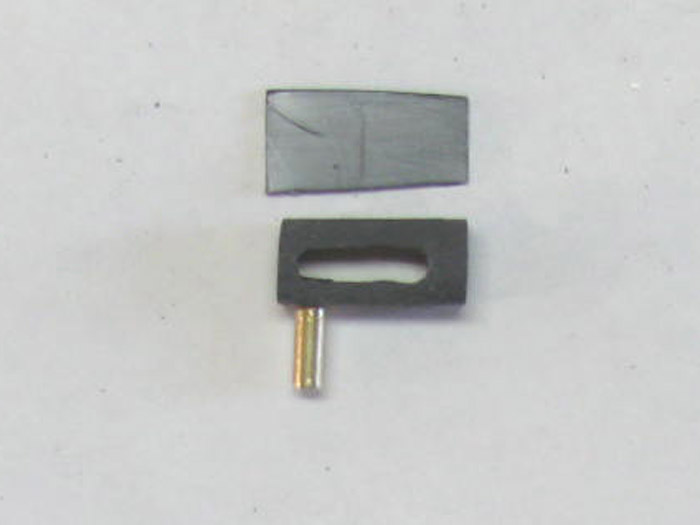

I did not think the plastic bow plane operating parts would hold up.

Build new ones out of brass.

I cut several sizes of brass tubing to match the outside diameter and

the pin size.

I plan to use two wheel collars to make the control horn and connect

the two bow planes shafts together.

I made the brass horn by flattening 3/16" brass tubing.

Then I drilled a 1/8" hole on one end.

I put the wheel collars and the flat brass on a 1/8" shaft.

I soldered the three pieces together so I can get to the allen set

screws when in the boat.

The horn is long so I cut it to fit later.

I then drilled through the collars and brass strap to get the hole

large enough to accept the bow planes shaft.

This shaft is smaller than the hole in the plastic bow pieces.

I made two short brass tubes to act as bushings and pushed them through

the hull with a spot of CA on them.

I had a long shaft going through both hull halves and bushings to keep

every thing straight.

I am working on the rods that lift and lower the planes but I have nothing

worth taking photos of now.

They are long so I have enough to figure out how and where to put the

control horns to make them work.

I made one using a ring that I saw in someone's video.

There was just too much slack, so I need to find a couple of ball links.

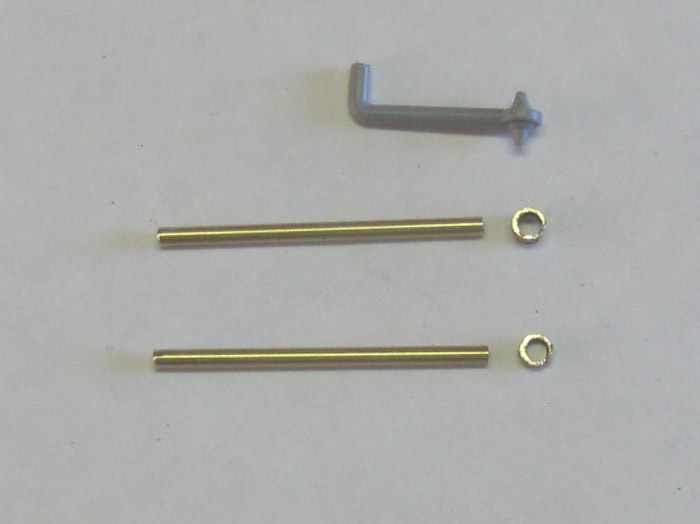

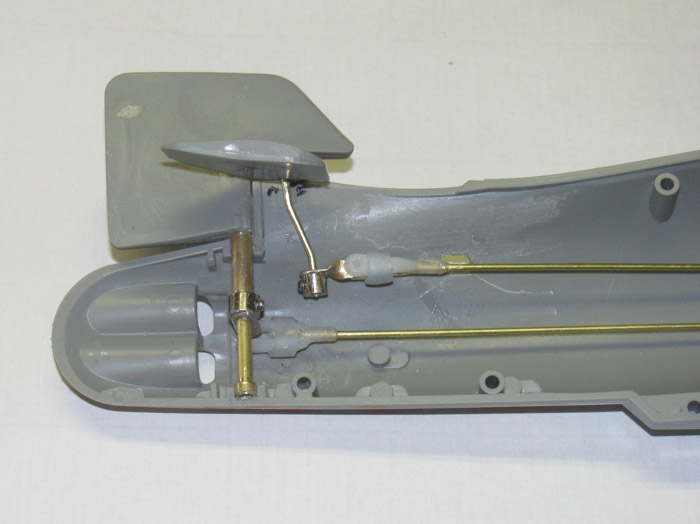

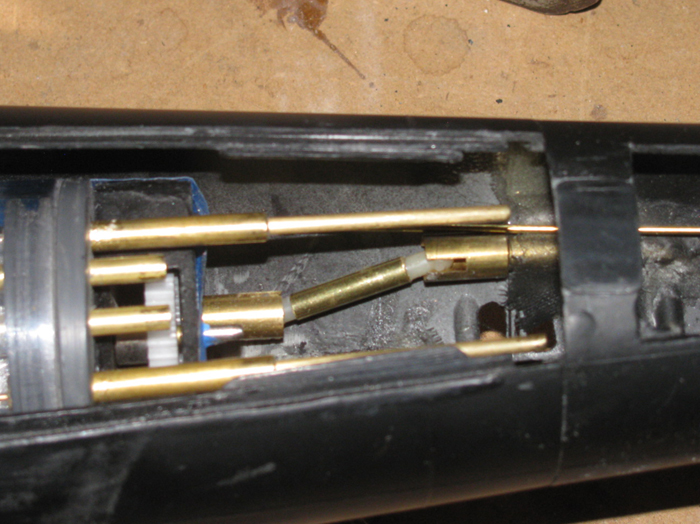

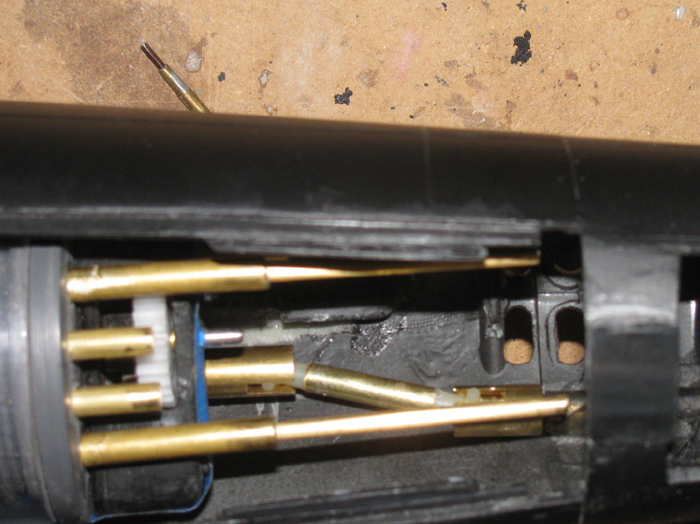

Here the bow planes rotation control rod is in the wheel collar connector.

nothing is permanent yet.

November 24th =================================================

A day has pasted and I had seen.

The doors were cut out and some glazing has been done.

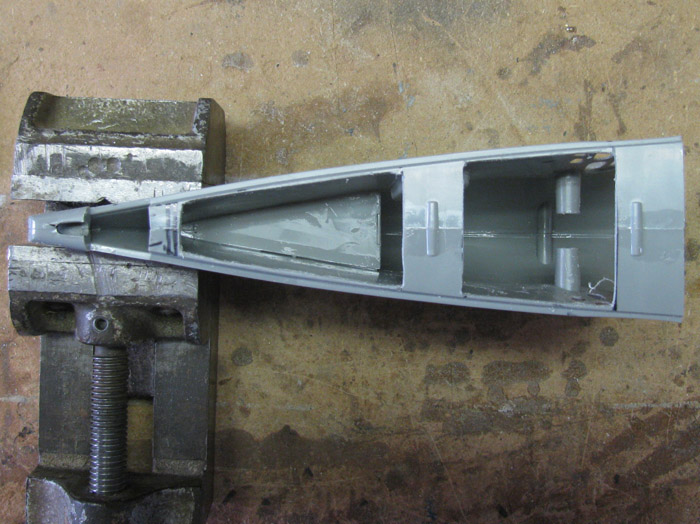

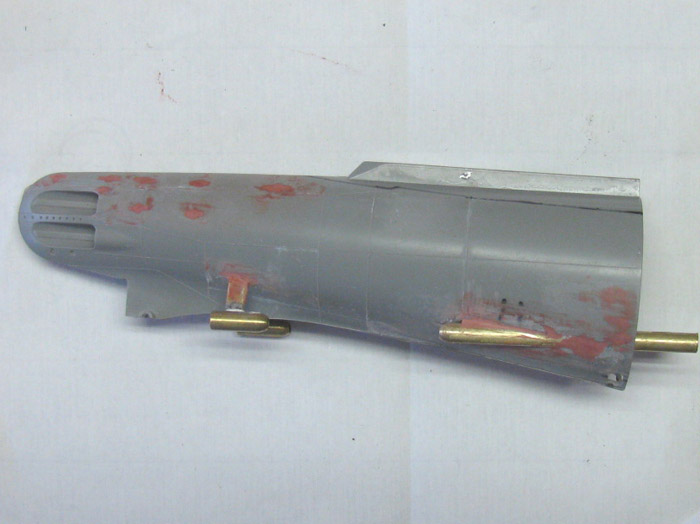

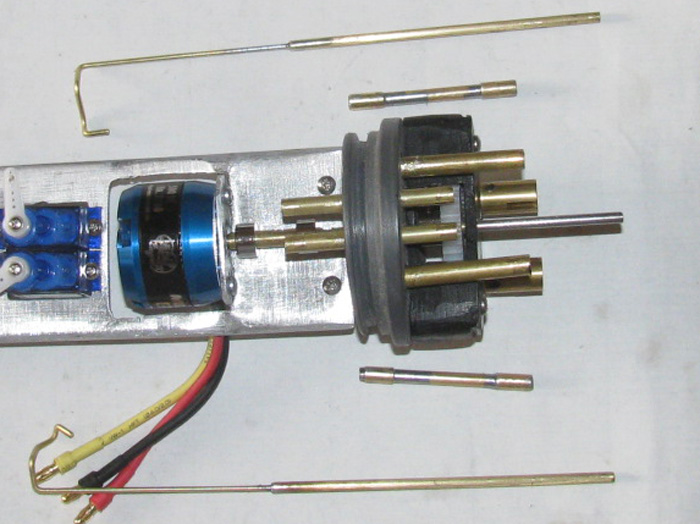

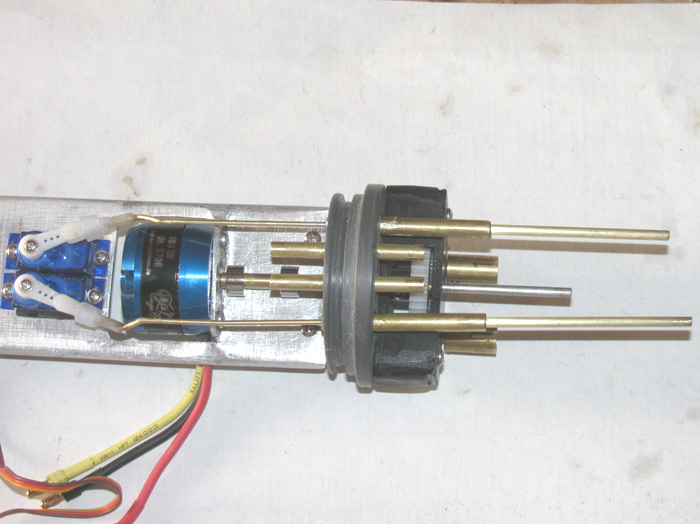

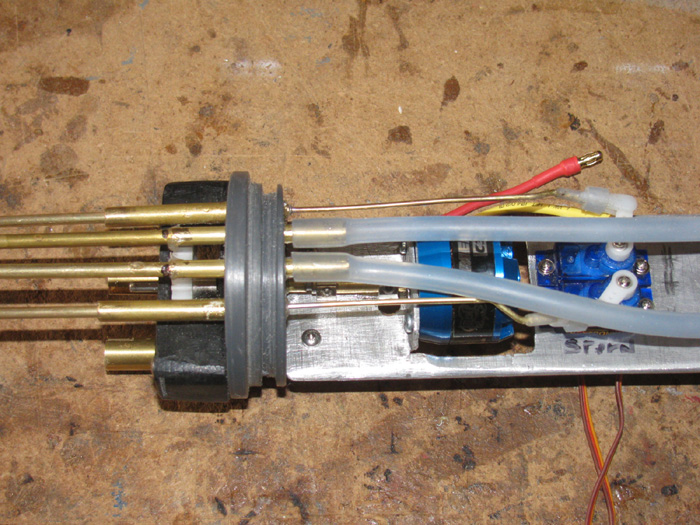

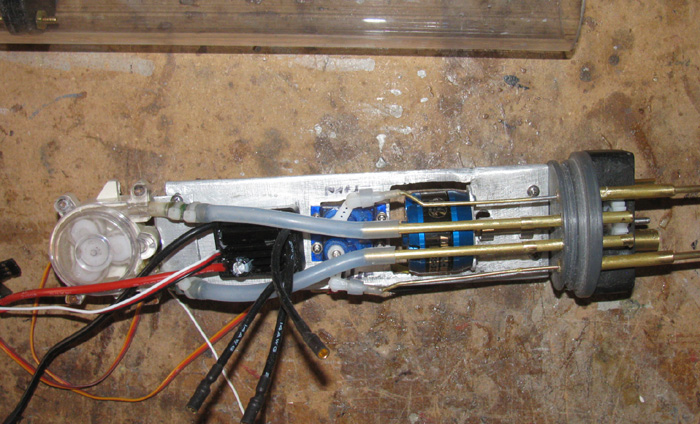

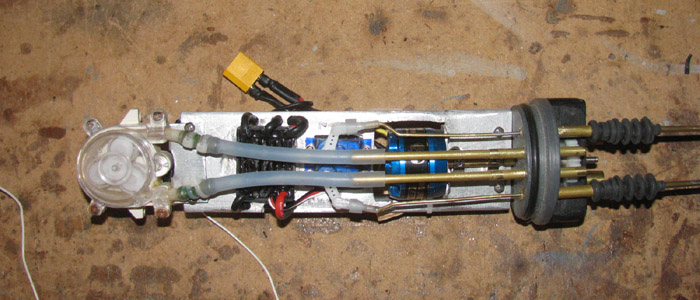

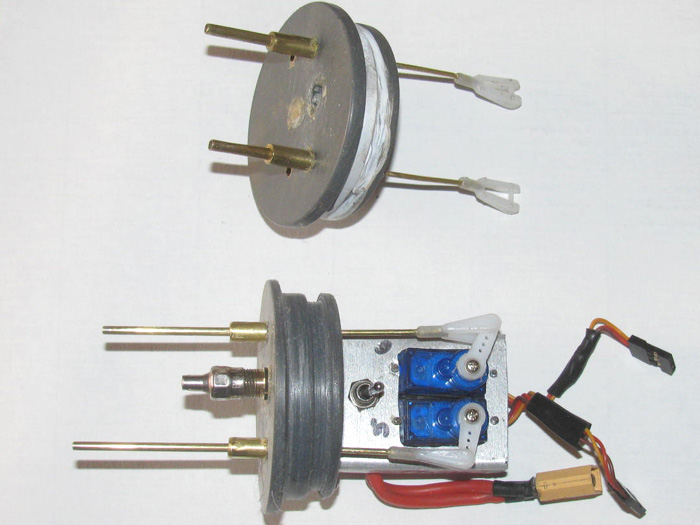

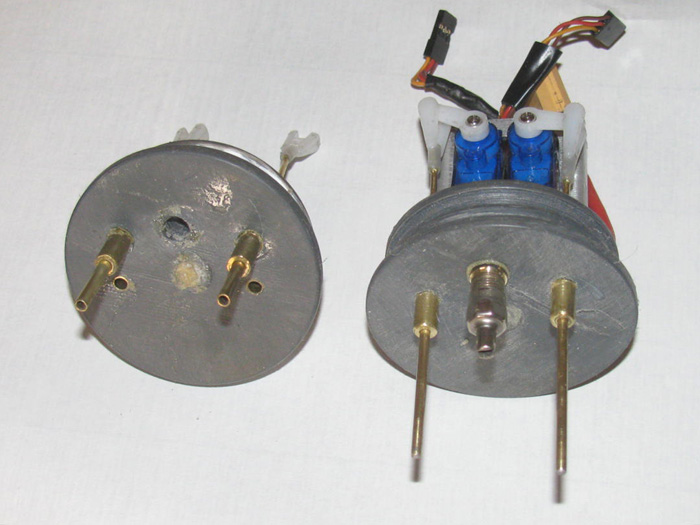

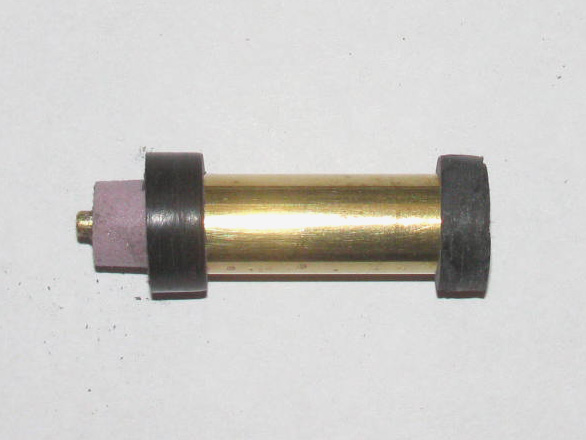

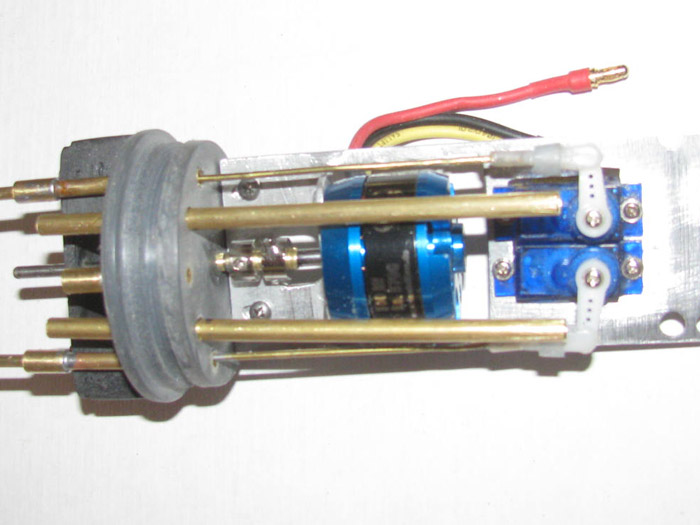

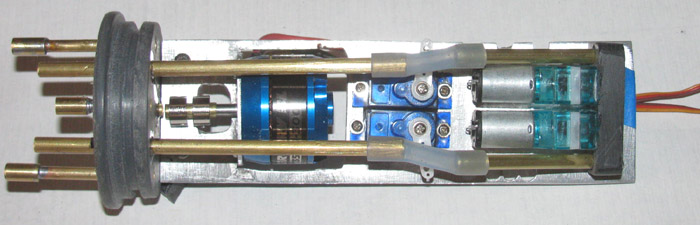

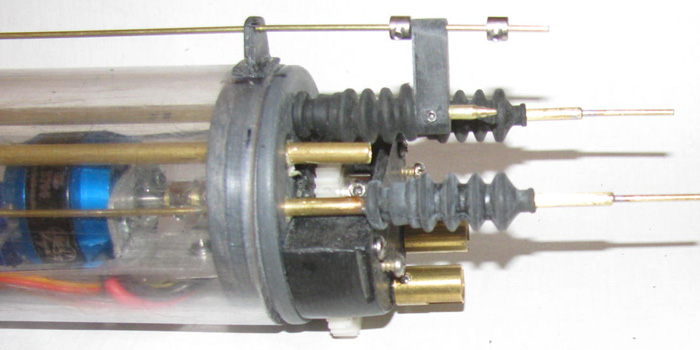

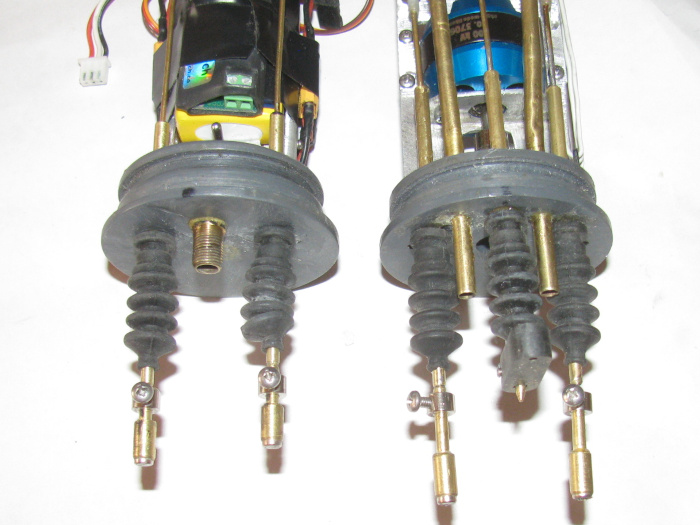

Back to the propeller shaft struts and through hull tube.

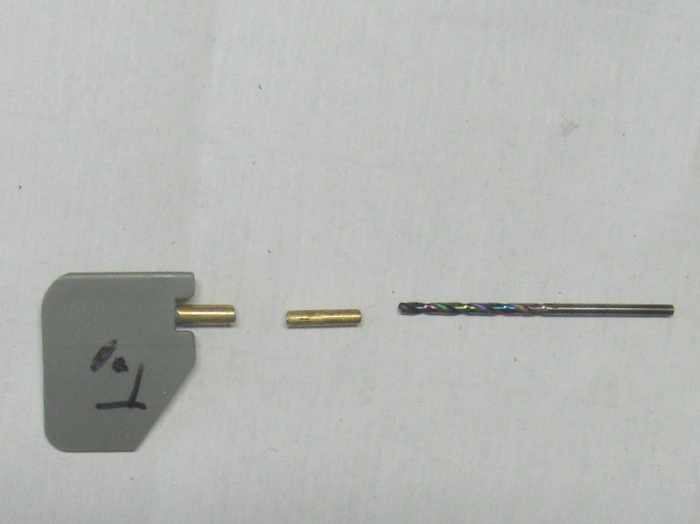

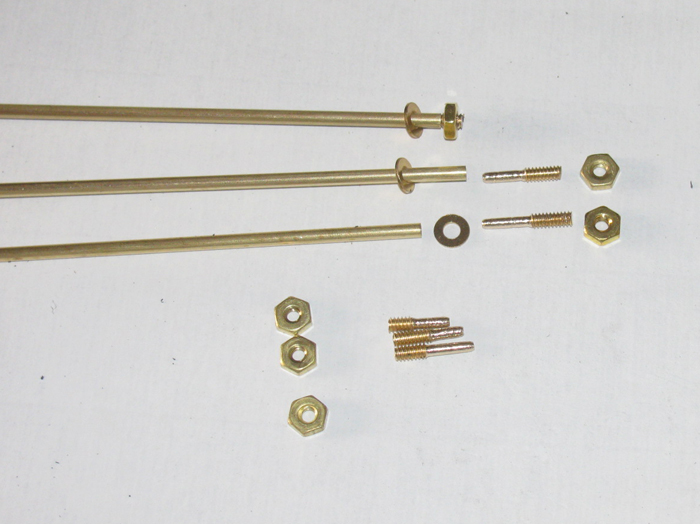

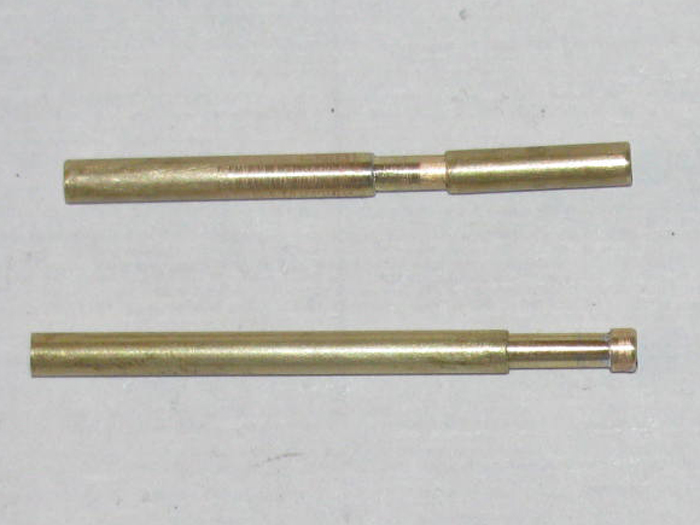

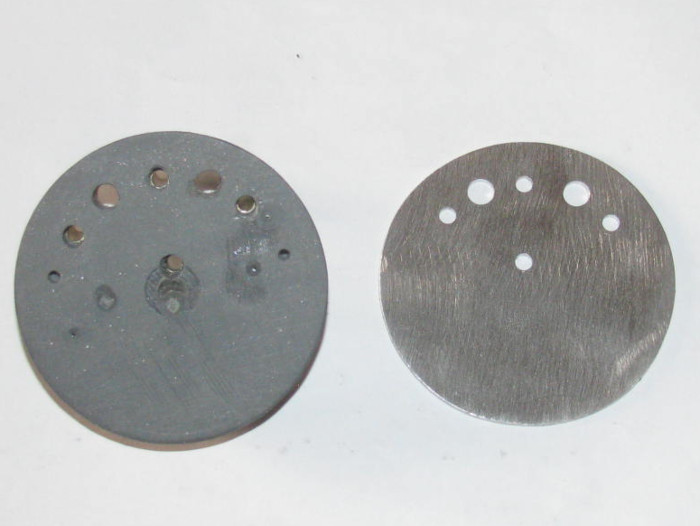

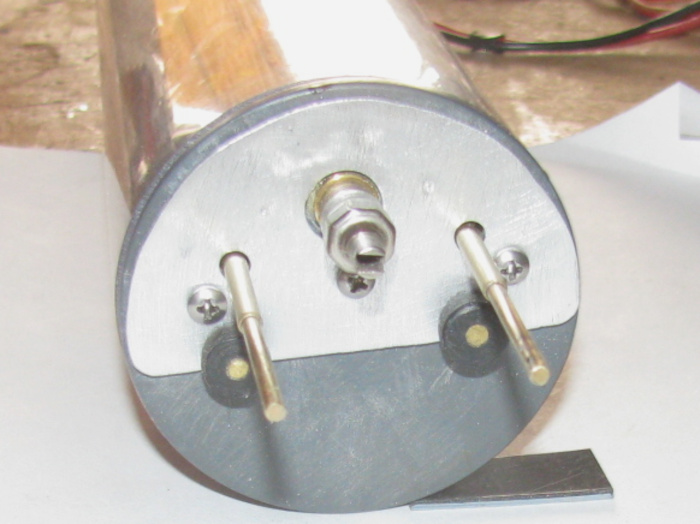

Here are all the parts.

I have shaped the ends of 3 of the strut bearings.

The middle one is still to be shaped.

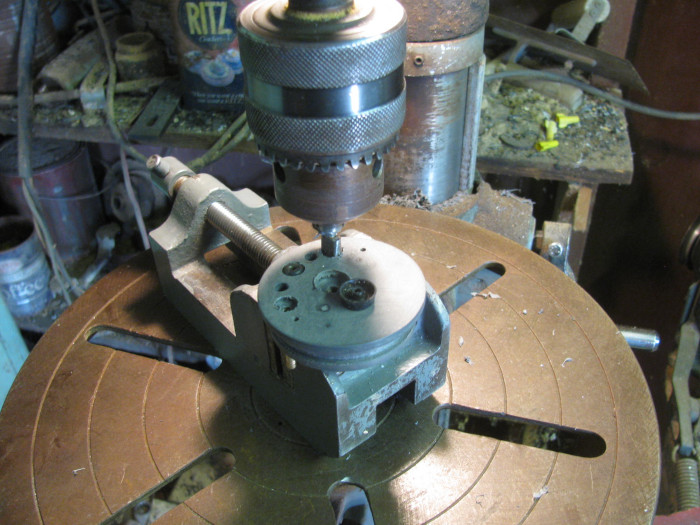

Chucked the tubes in to the drill press and with a fine file I shaped

the ends.

My test propeller shaft is brass.

The shaft will be stainless when I get to the end.

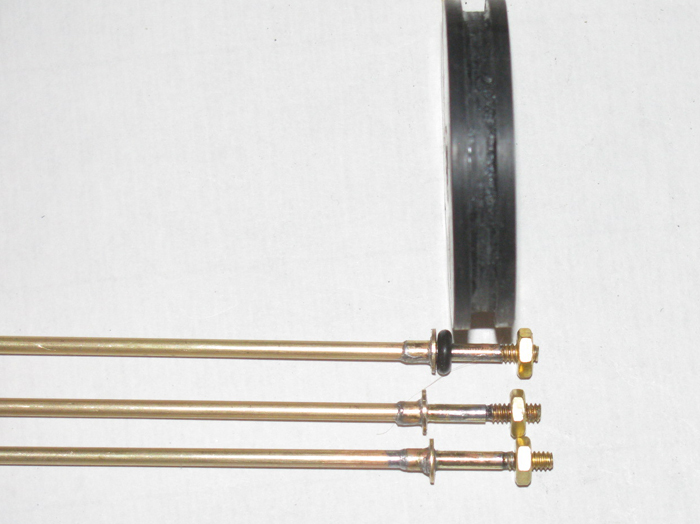

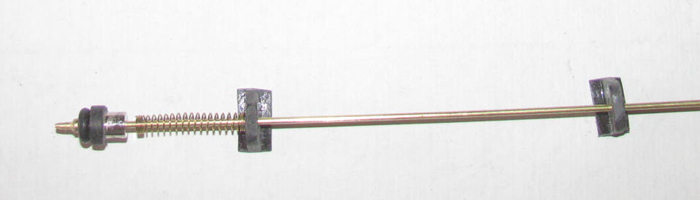

I now have the shaft bearings and through hull tube done.

Except I have not cut the through hull tube to length which I do not

know until I get the rear strut made and mounted.

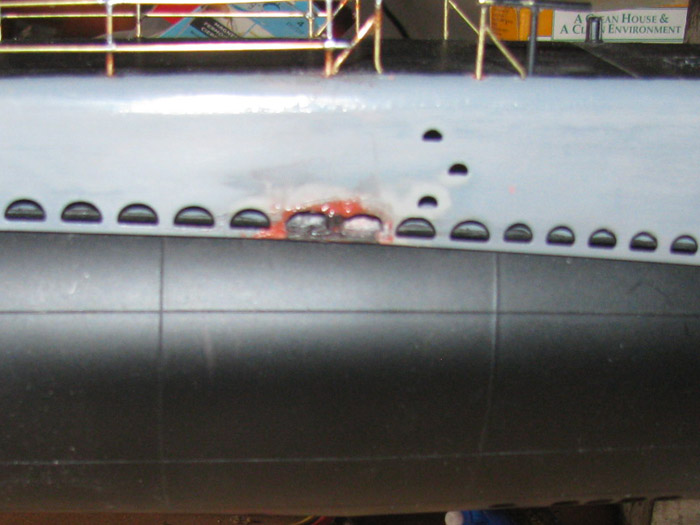

While an making shaft parts, I might as well cut the opening in the

hull for the tube.

Drilled a couple of 1/8" holes in the middle.

Using the dremel, I enlarged the hole by tilting the dremel on it's

side and cutting the plastic away.

When I got close to the guide lines, I went to a small half round file.

The hole is ragged but there will be filler later.

Filed down to the lines and test fitted the through hull tube.

Got the tube to meet the hull at the guide line.

Will do final fit once the rear strut is in and holding the propeller

shaft in the correct line.

November 25th =================================================

Fitted the bow planes.

cut the through control tubes.

Giving about 3/32" of gap to make sure everything turns.

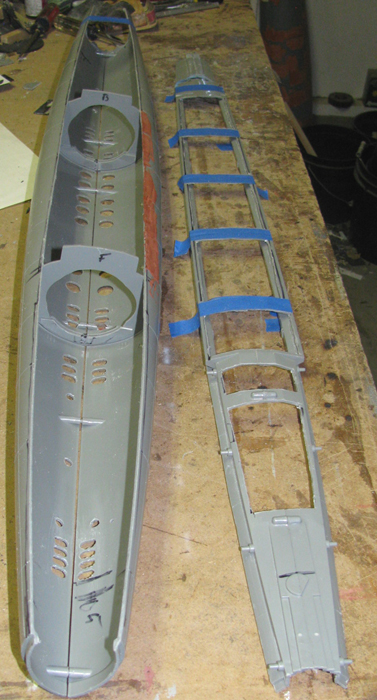

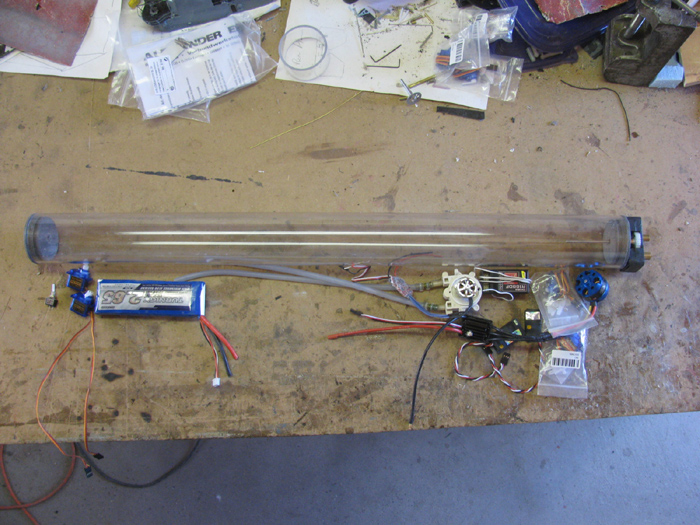

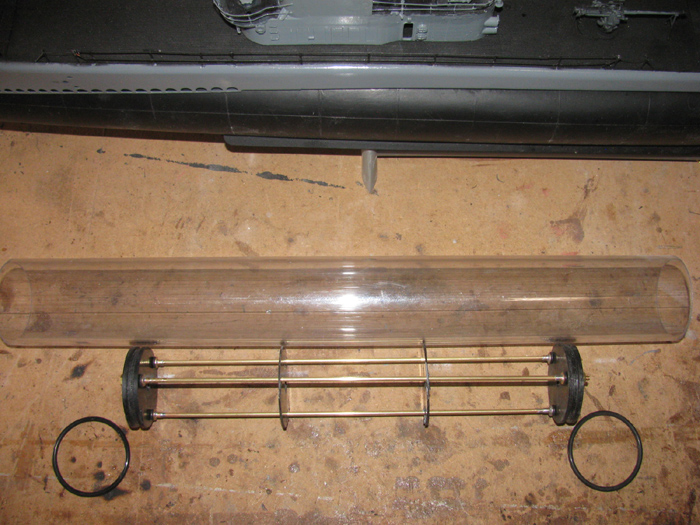

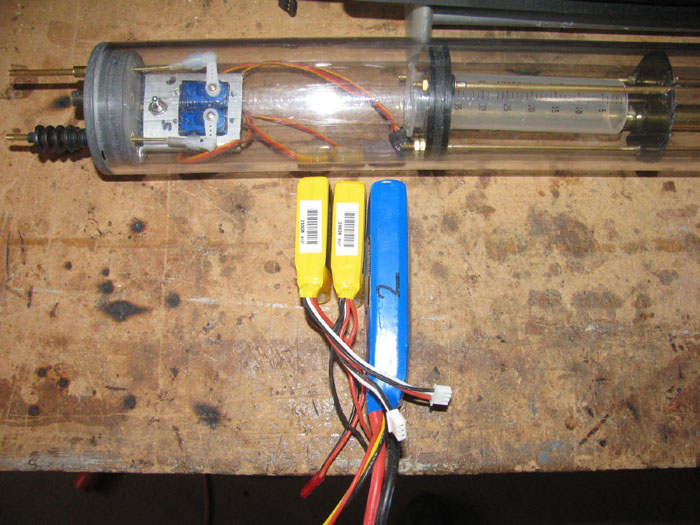

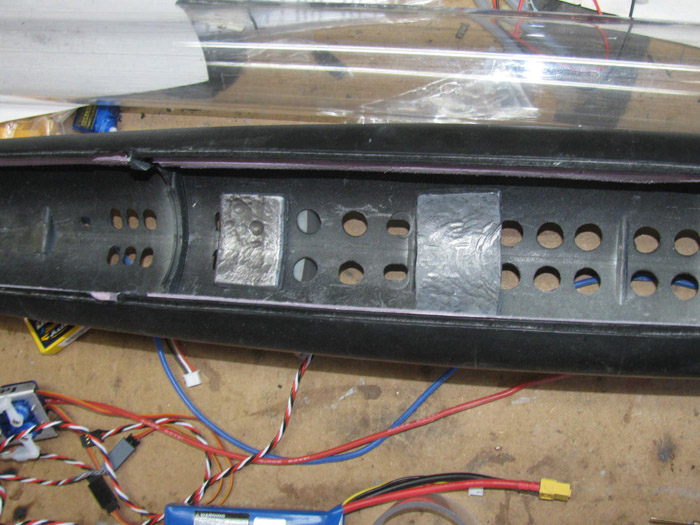

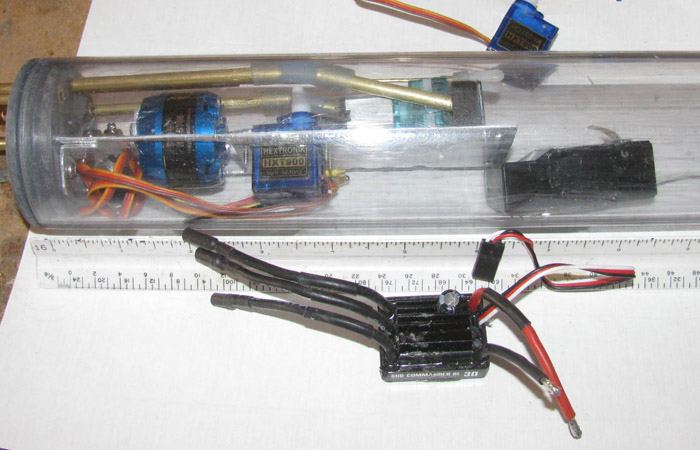

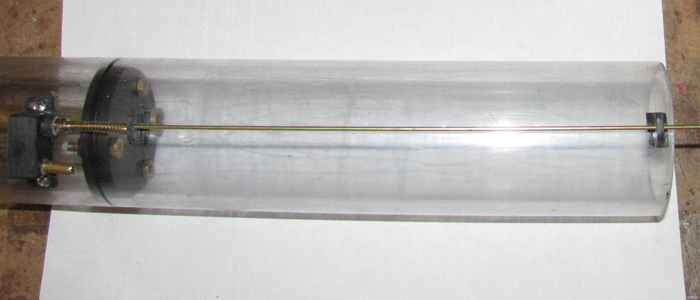

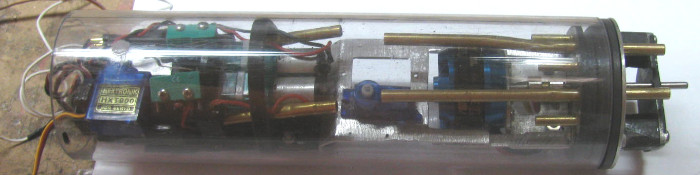

I cut the 2.5" wtc tube at 19" for the GW.

That left me with 29.5" for the Gato.

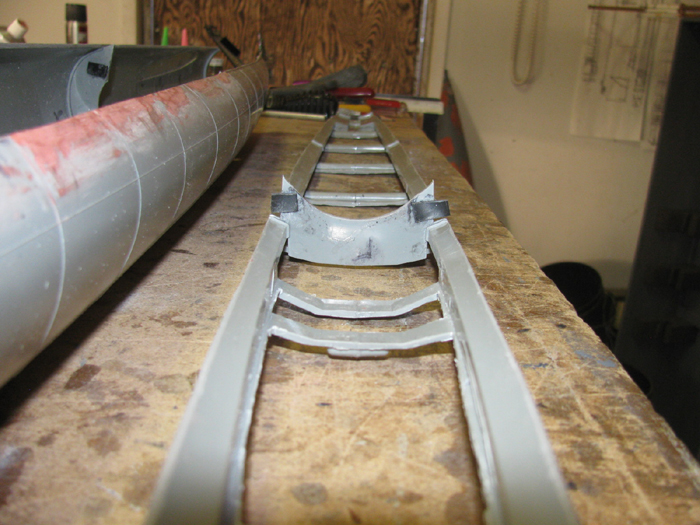

Set the cylinder on the two plastic frames.

Did not require much to get the tube to slide through.

I want the cylinder to sit about 1/8" above the locating pins on the

hull.

This is room for lead weight ballast, later.

Two frames sitting in the hull half.

Wanted to look at the cylinder in the frames for fit.

There is room to move the cylinder forward or backward when I get to

trimming.

I have not decided where I will cut the hull fro access.

Waterline.

Center of the hull.

Inside the deck fairing where it meets the hull.

I will finish the bow planes installation and the stern rudder, planes

and propeller shafts bow section

before I decide.

I originally thought I would cut it at the center o the hull but now

having talked with a couple of other builder, I may cut it under the deck.

They say the 2.5" cylinder will drop through the opening with no problem

but the linkage may be a bit tight to get to.

So if I finish the bow and stern sections before attaching them to

the hull, I may be able to get to make the connection in a place I can

reach. (fat fingers)

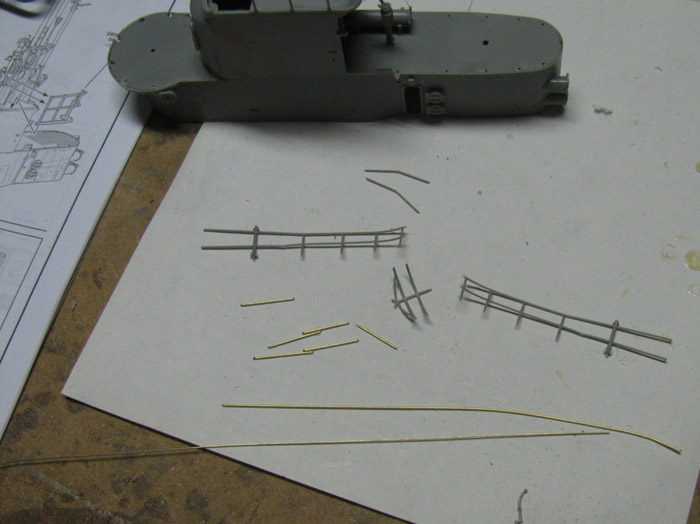

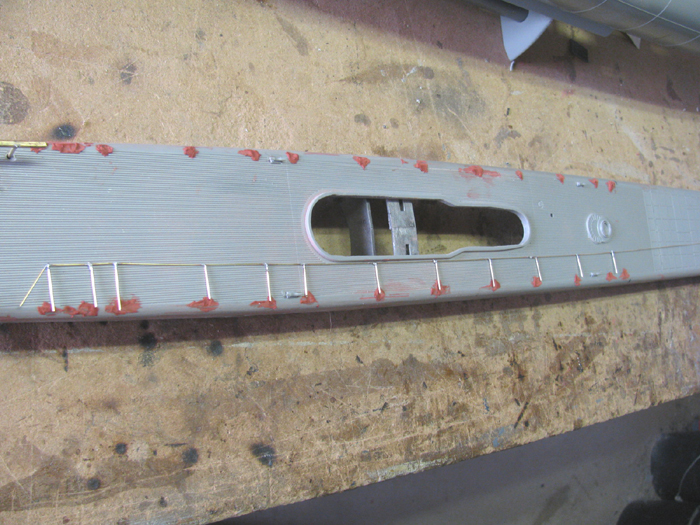

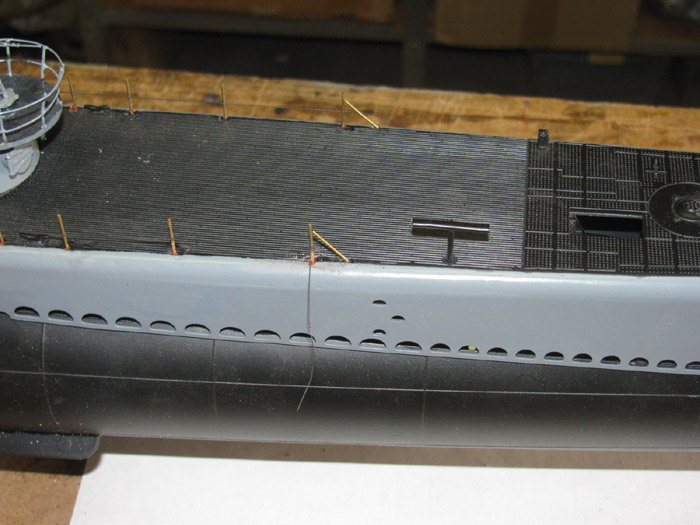

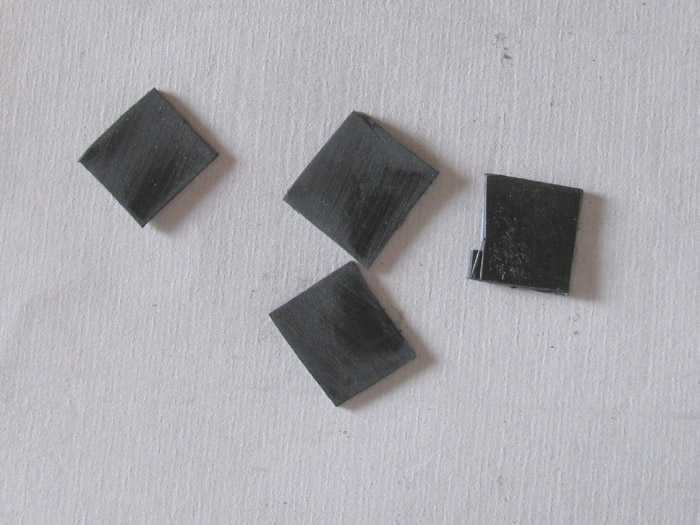

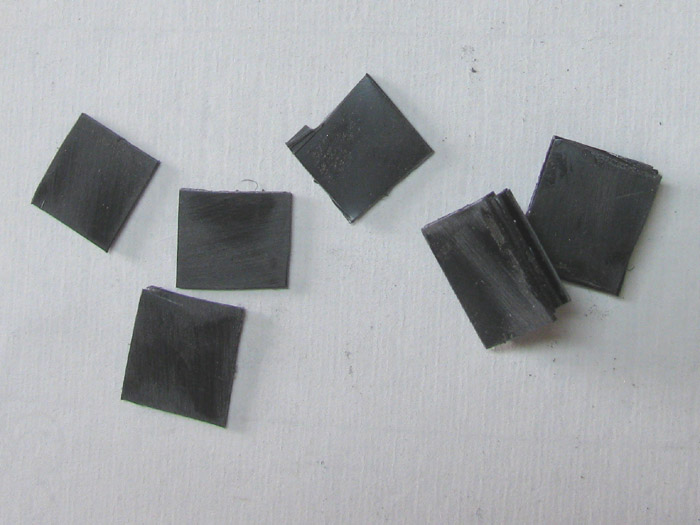

Here I have cut a few parts to start the rear gun deck railing.

I can see I may have to build jig to hold these small parts.

The single part at the bottom is the stanchion.

That is going to be something that needs a jig so I can make 8 of those.

November 26th =================================================

I had a little time this morning.

Out to the shop I went.

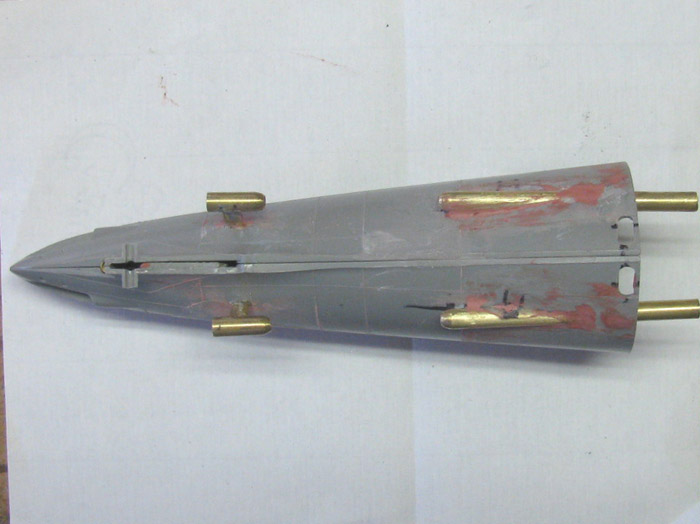

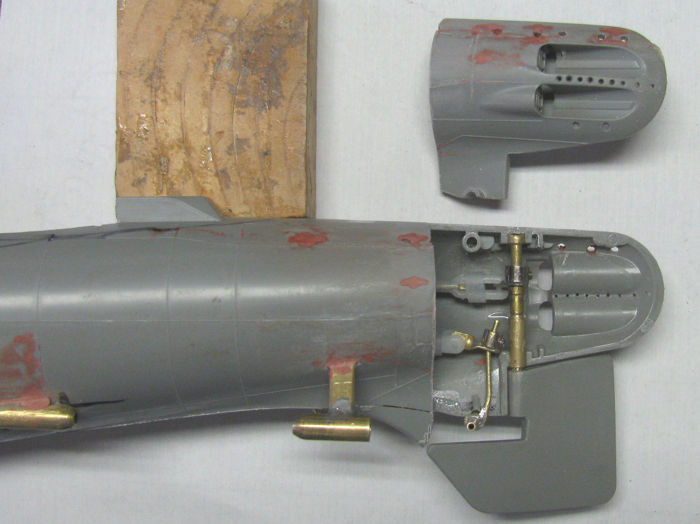

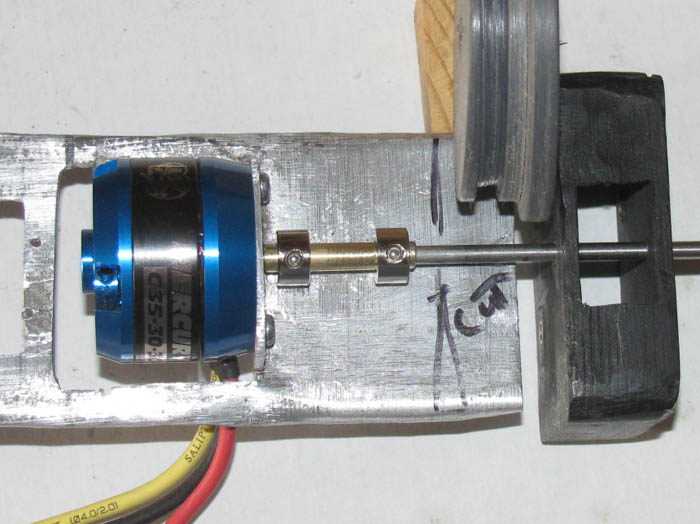

Made two brass rear bearing and strut for the propeller shaft.

Took some brass tubing and flattened tit to make the airfoil strut pieces.

Flattened one end at the strut length and bent the flatten ends.

1 right and 1 left.

Marked the brass bearing housing to locate the strut centers.

Soldered the struts on to the bearing housing.

I drilled a hole in the stern section at the strut location.

Slowly lengthened the hole to accept the brass strut.

Once I get to where I can install the propeller shaft to get the correct

shaft angle, I will then make permanent the rear strut.

The flat bent section of the strut goes through the hull and will be

bent to lay flat on the inside of the hull.

This will get me a bonding surface to take all the load.

Now later in the day after doing real life stuff, I had about 20 minutes

I could spend in the shop.

I went to town and picked up some 3/32" brass tubing while there.

This would be for the bow planes struts.

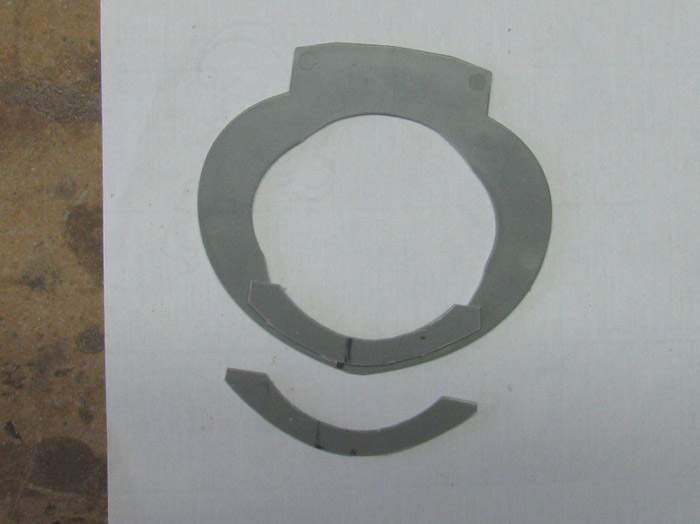

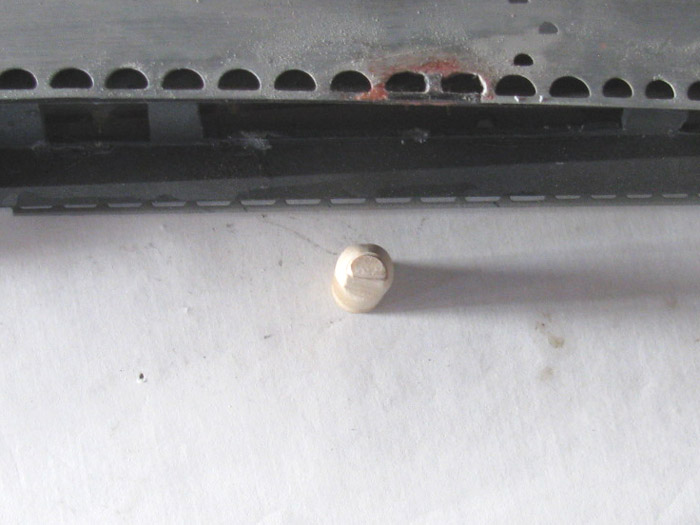

I cut 2 rings and 2 struts.

The rings will be soldered on to the ends of the struts. (done)

I did not like the slop the connecting pin had and would let the bow

planes move up and down about 1/2" before stopping it.

I see others have used small ball connectors to deal with the slop.

Before I can get to a hobby store that might have those, I thought

I would try this.

I filled the ring with good silicone rubber.

Once it cures completely, I will drill a 1/16" hole through the center

for the hinge pin.

The silicone should keep the pin centered in the ring and also allow

the pin to rotate side to side to let the bow planes rotate for dive and

rise.

More to come on this test.

Got to build a bow plane mechanism .

Then I can figure out where to cut the long strut.

November 27th =================================================

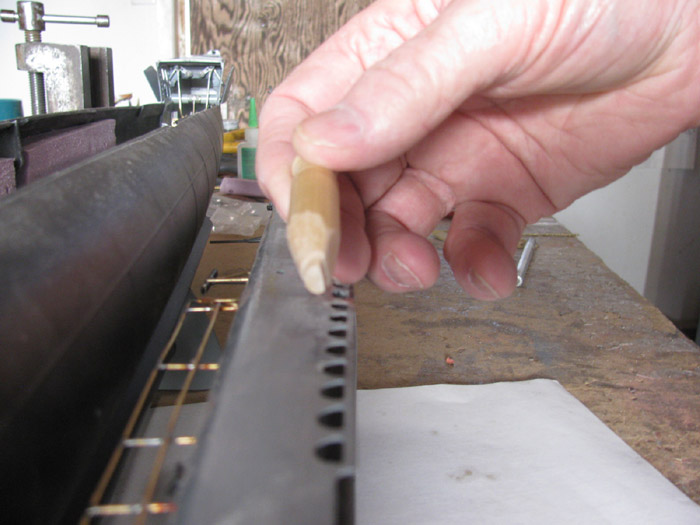

The silicone has cured in the strut rod rings.

Cleaned it up with a knife and file.

Uses a sharpened 1/16" rod to punch a hole through the silicone.

The silicone hole closed up which made it tight on the hinge pin.

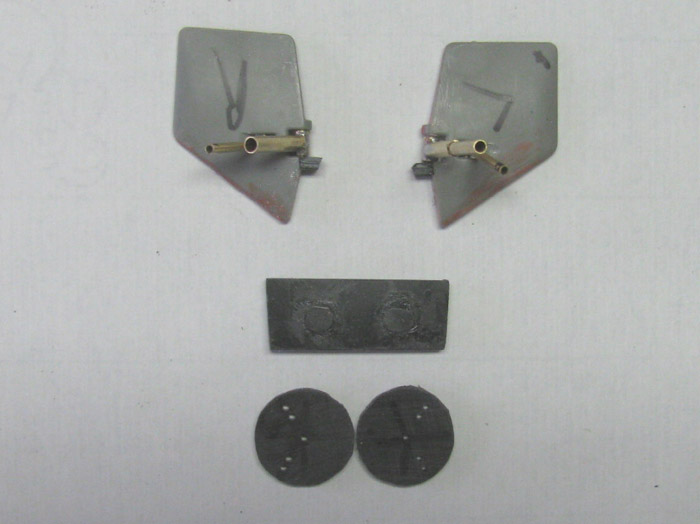

Worked on the bow planes.

Finished the assembly of the bow planes.

I used a 1/16" drill bit to lengthen the hinge pin slots to use a longer

pin.

Dry fit all the parts then assembled the bow planes.

Bond the parts.

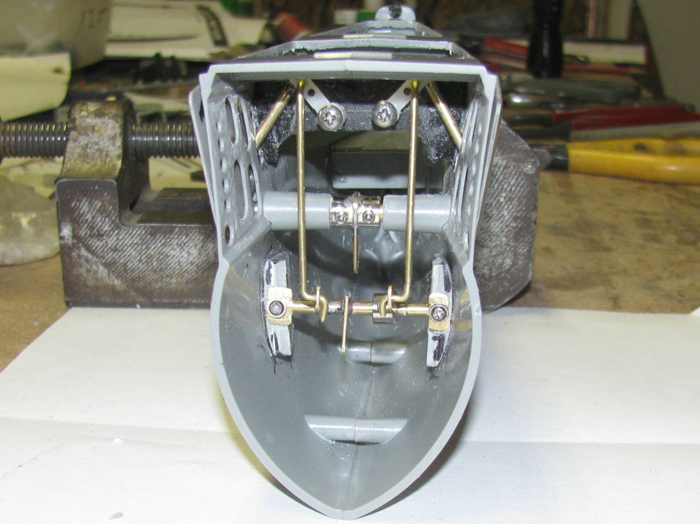

Here are the 2 planes with the struts in place.

1 is set in to the bow half.

The start of the mechanism to lower and raise the planes started.

Look at the planes raised but not fitted. (have to make the raise and

lower mechanism first)

bow planes lowered.

November 28th =================================================

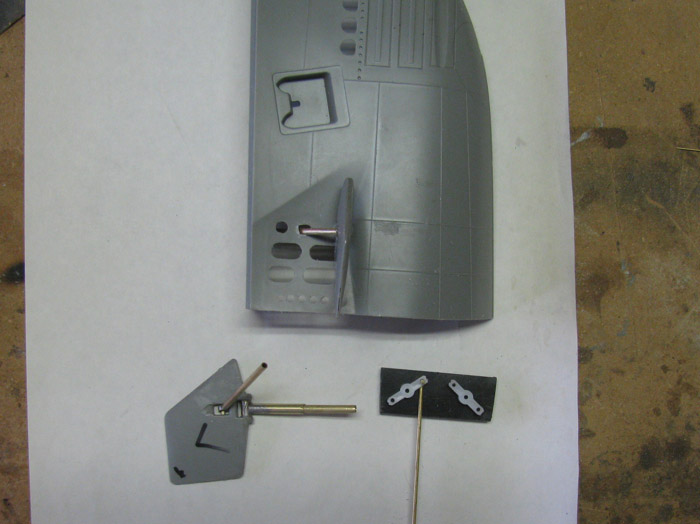

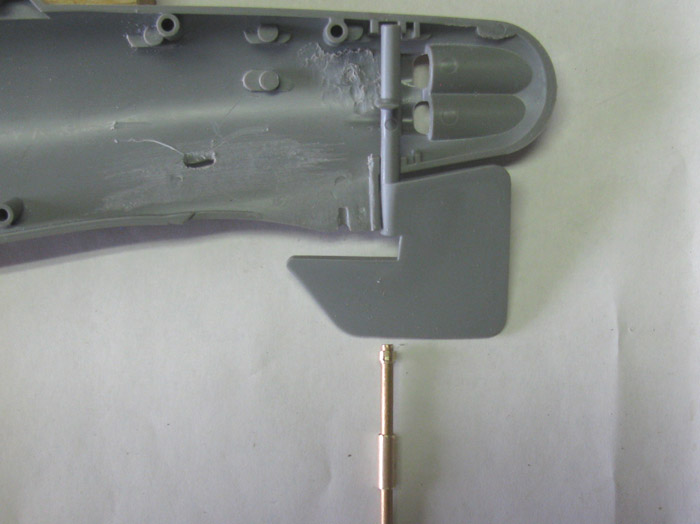

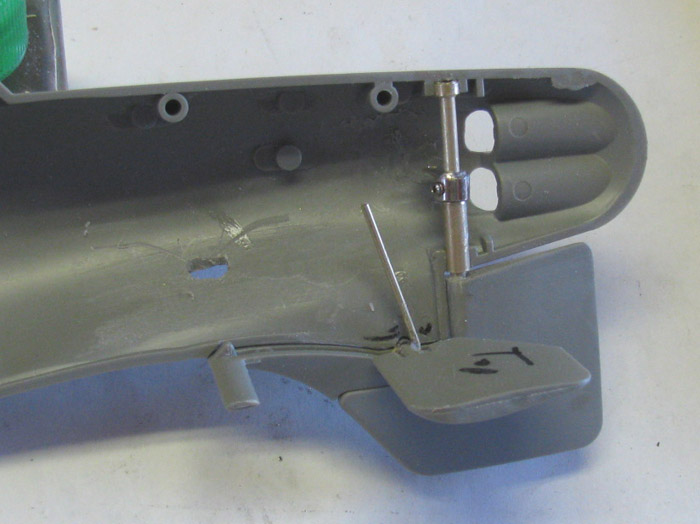

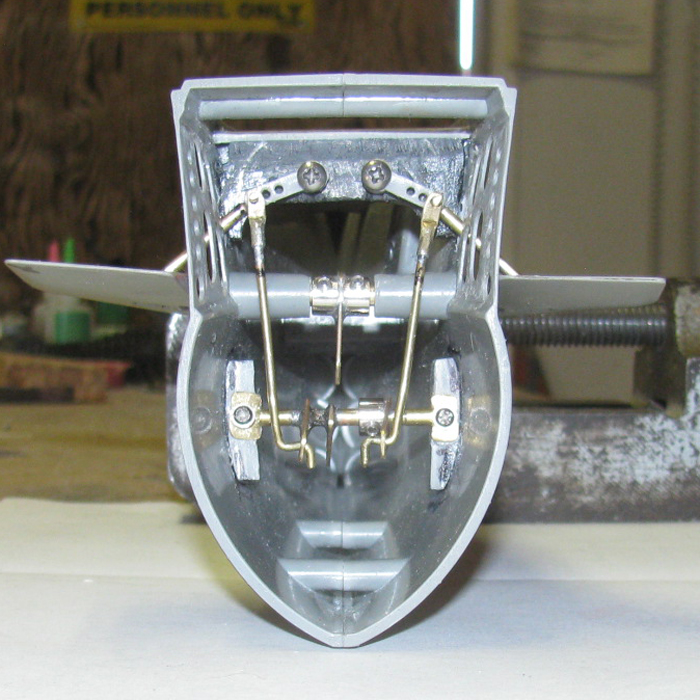

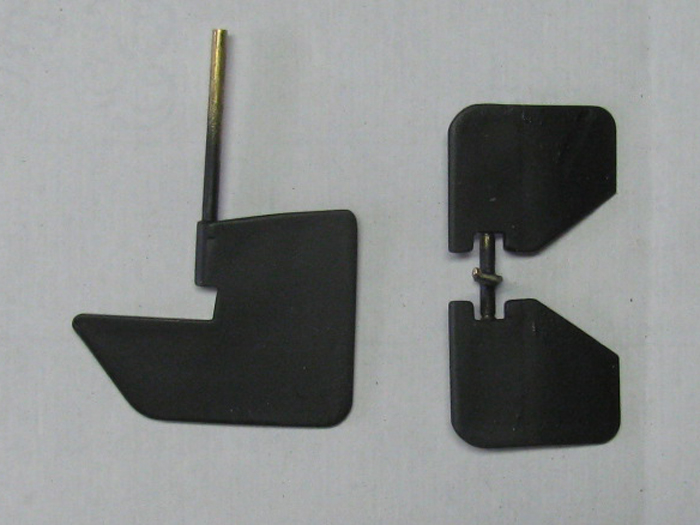

Think I will work on the rudder and the stern planes.

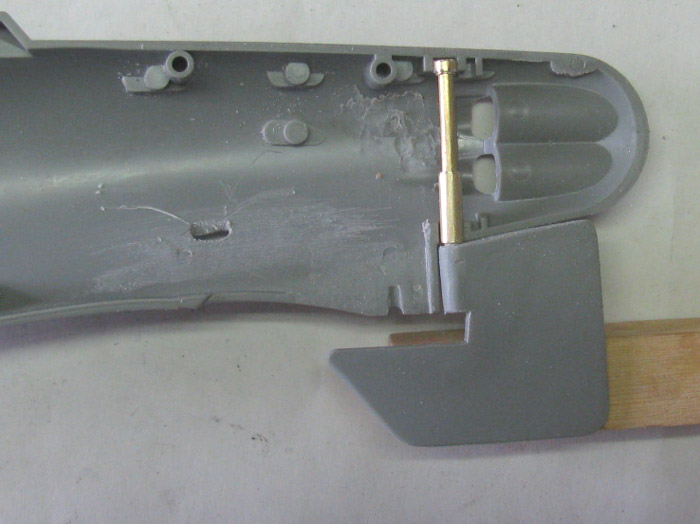

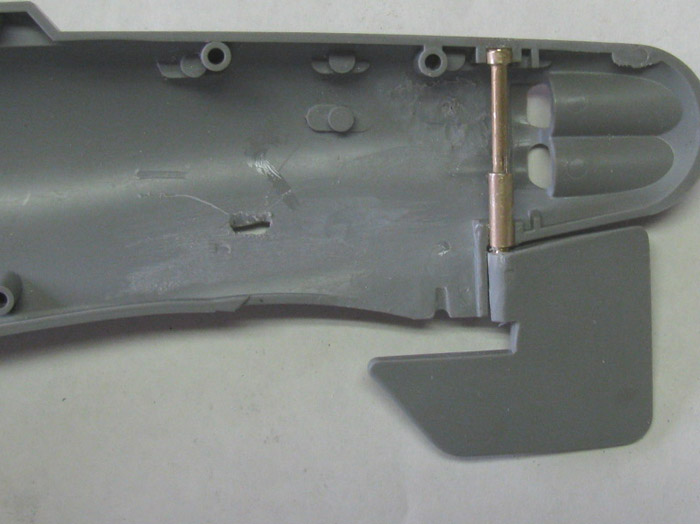

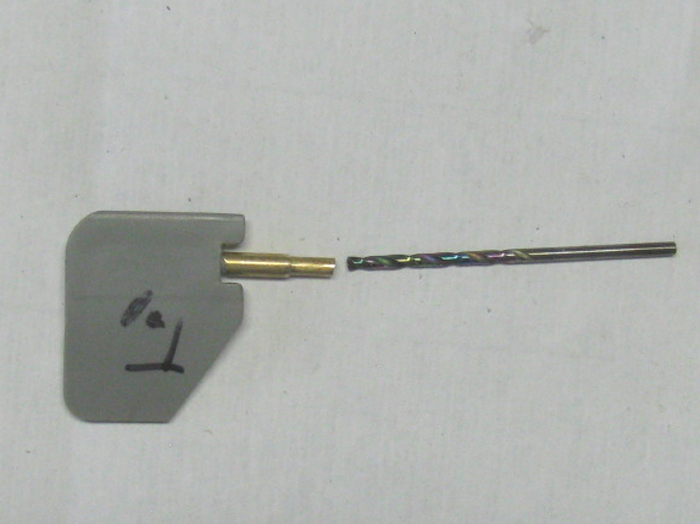

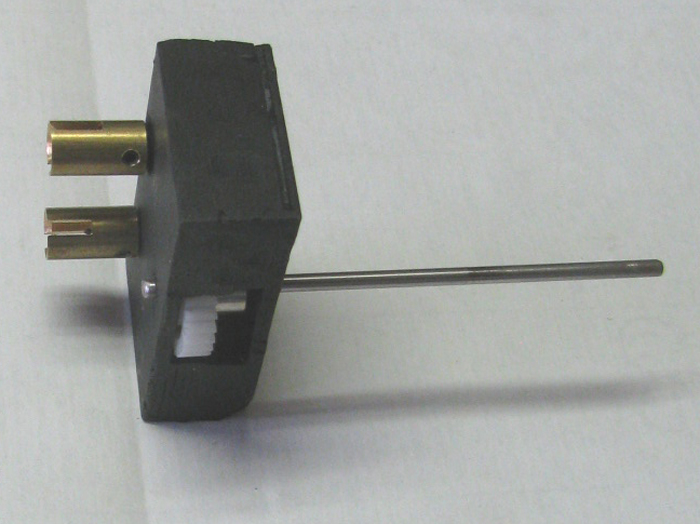

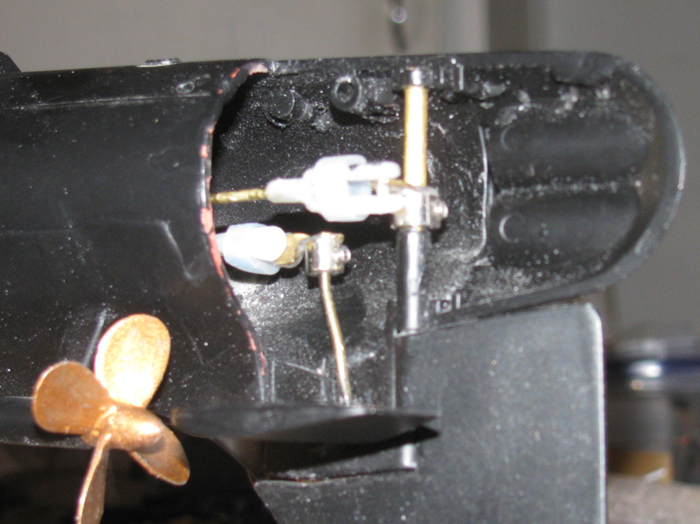

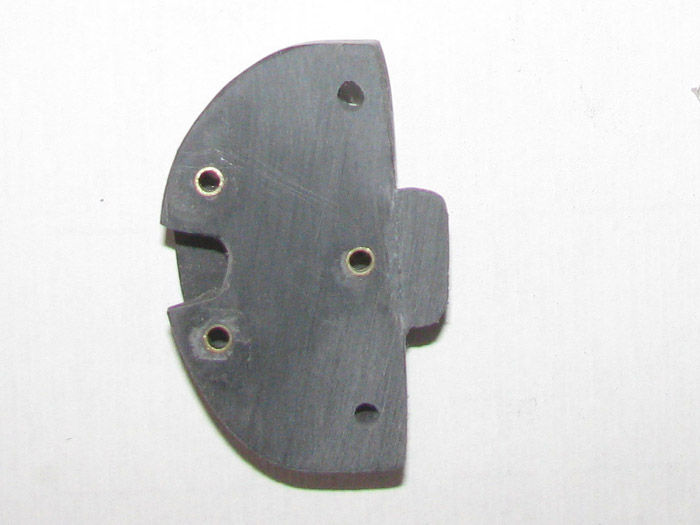

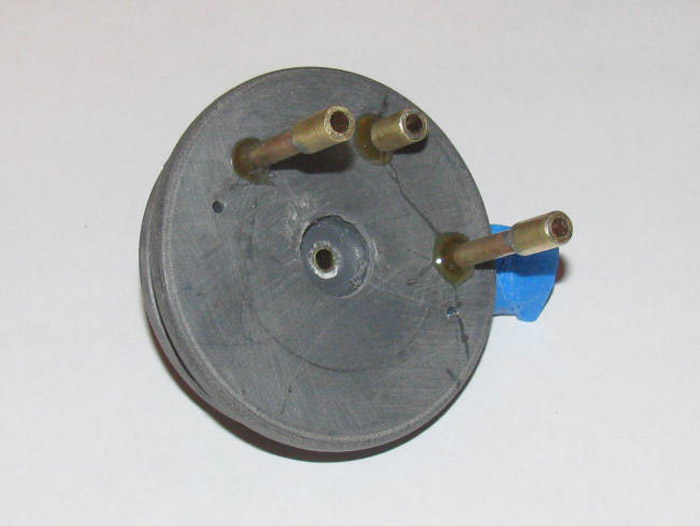

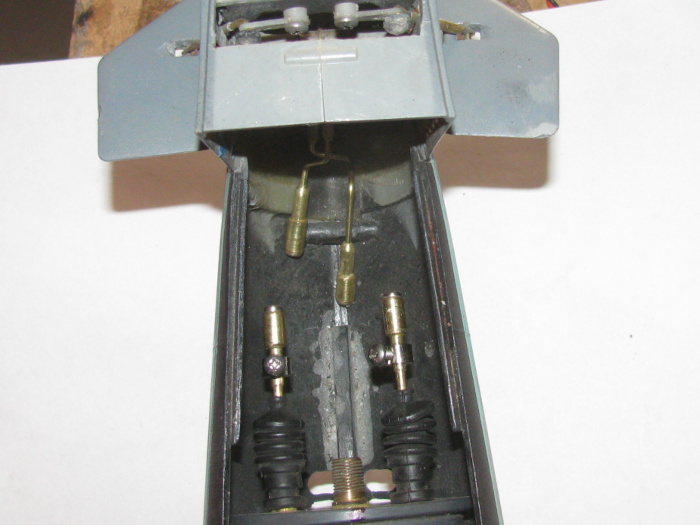

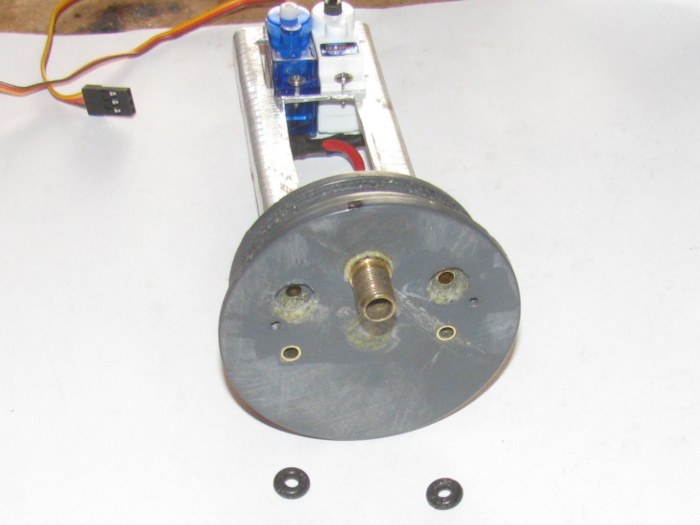

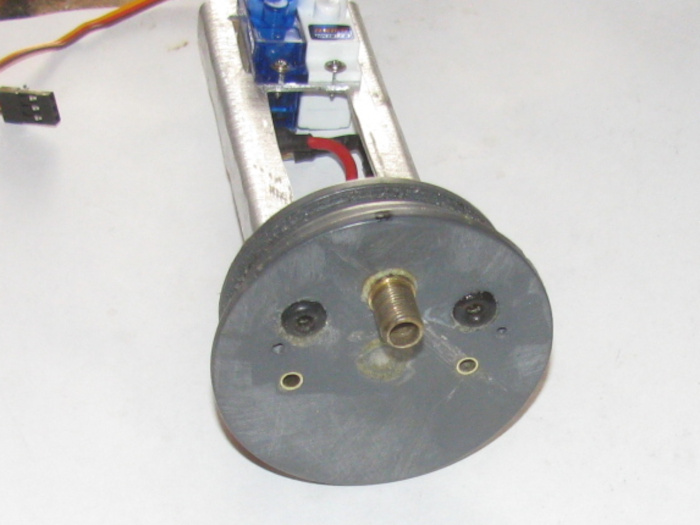

Here is the rudder and the bearing system I plan to use.

The vertical brass tubing is the rudder post.

The 2 little tubing piece at the top and the bottom are shims to size

the locations in the hull to accept the 1/8" brass rudder post.

They will be permanently glued in to the hull.

The small pieces have been glued together and then slipped on to the

rudder post.

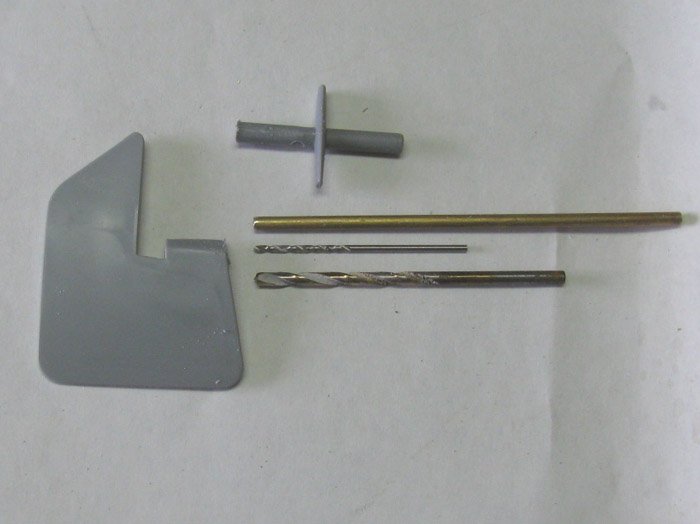

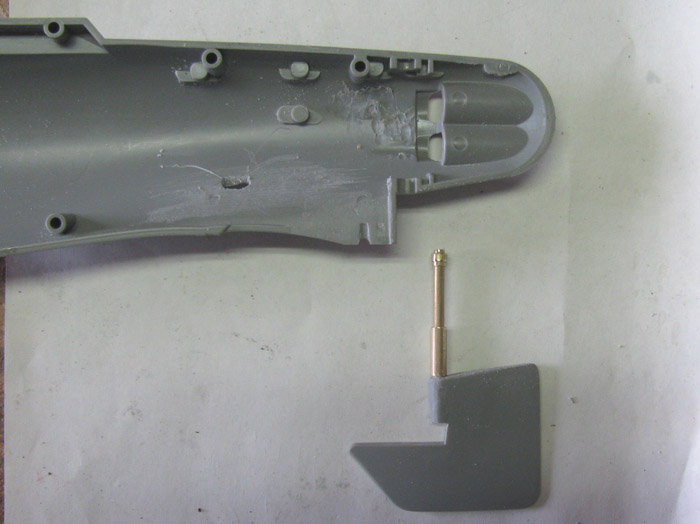

Original rudder.

Getting read to cut the post off flush with the top of the rudder.

Cut rudder post.

New brass 1/8" rudder post tube.

1/16" pilot drill bit.

1/8" drill bit sized for post.

New rudder post with sizing rings slipped on.

Rudder post is not glued in to rudder yet.

I placed a small drop off CA on the bearing rest on the hull.

I place the shims on with my fingers and wiped excess CA off with rag.

Slid rudder post thought the shims to hold them straight.

Hit them with kicker and removed the rudder.

Test fitting of rudder post and trimming to get correct length.

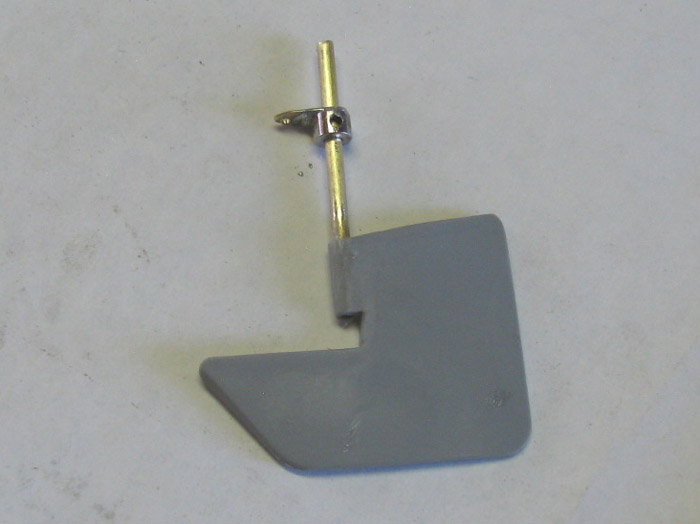

Made a control horn.

1/8" wheel collar with one side sanded for better soldering.

The horn is made form 3/16" brass tubing flatten in vise.

Soldered and drilled for post.

Rudder set in place.

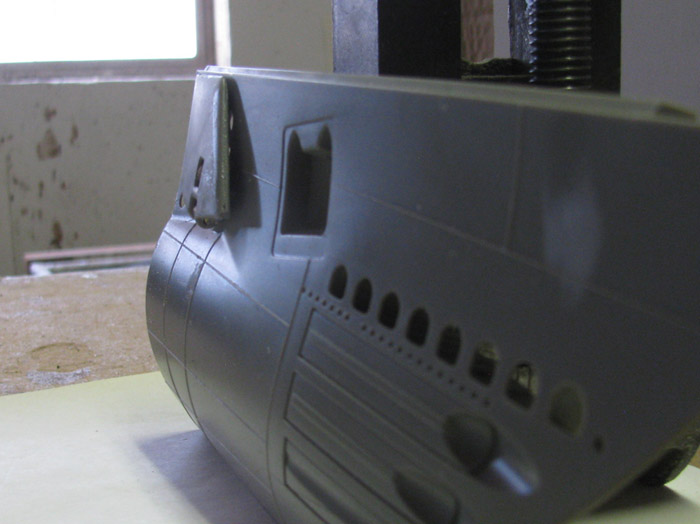

Made a control arm for the rear planes.

1/16" brass rod with a hook bent one end.

About 3/4 the way around.

The rod comes up on the rear side of the planes shaft.

Fits through slot in skag.

Glued to the planes shaft after twisting the hook around the shaft.

I should mention, I ground off the rudder post mounting sockets on both

sides of the hull.

They were about where the top of the planes control rod stops.

Also ground off 1 propeller guard socket near the same place as the

other socket I removed.

I probably could have left this socket.

The planes control rod has not been cut to size yet.

November 30th =================================================

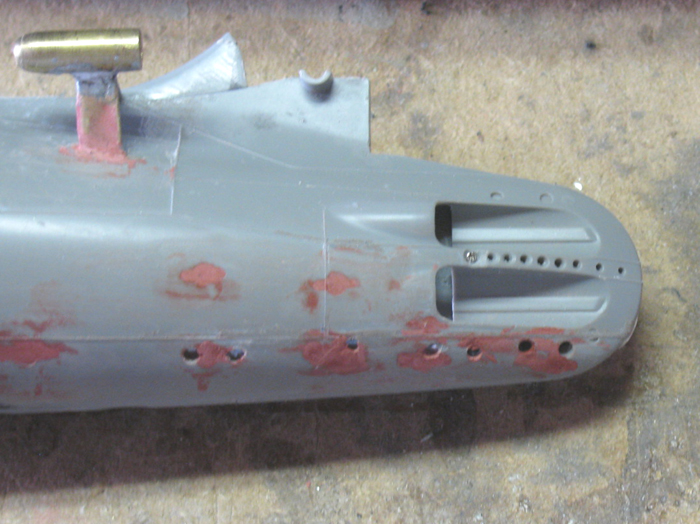

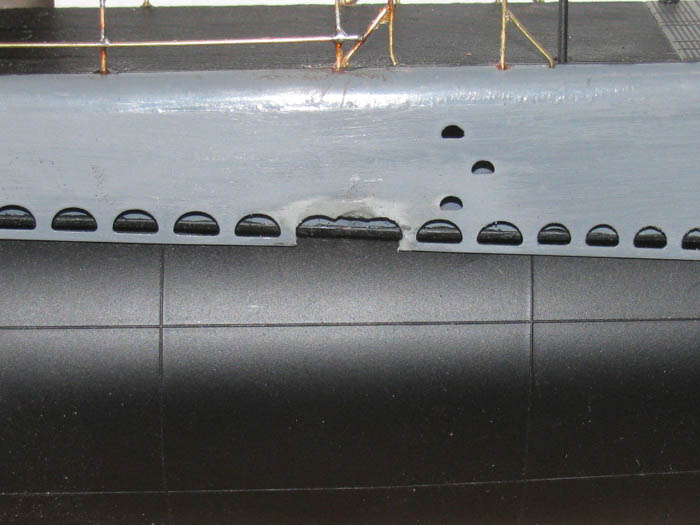

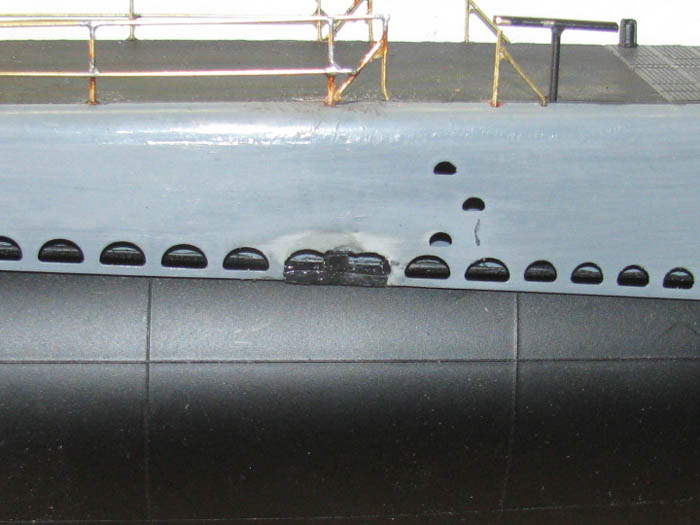

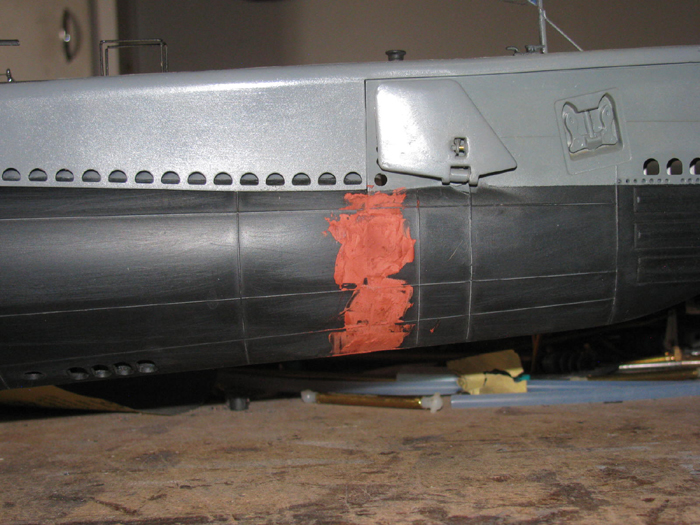

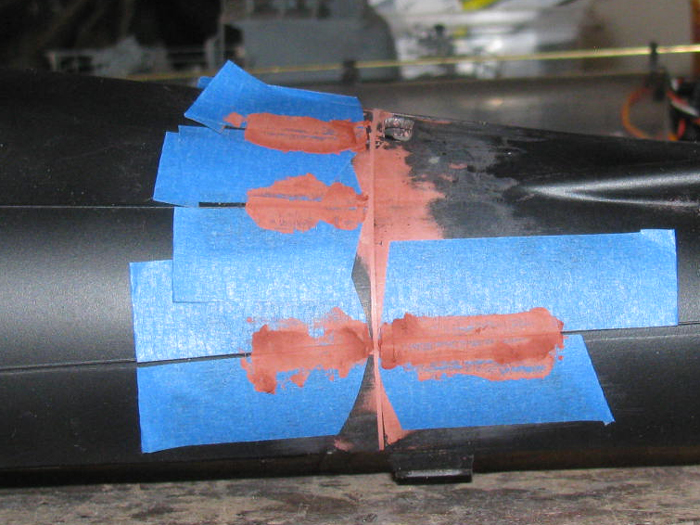

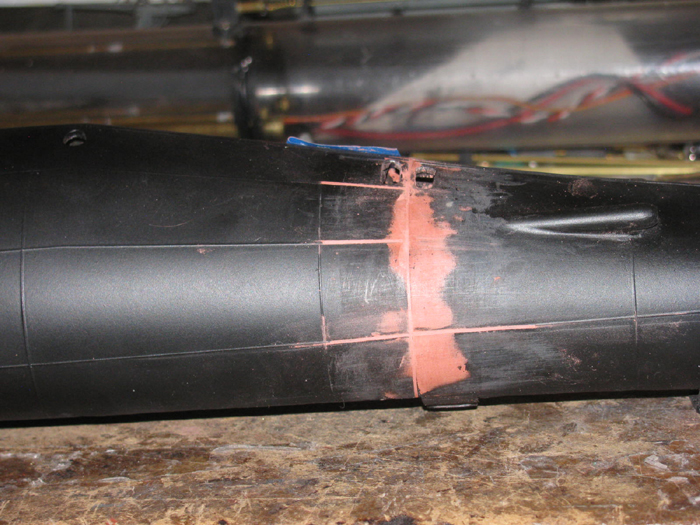

After removing the prop guard hull brackets and glazing the holes, there

was sanding to smooth the glaze down.

Doing this removed some of the weld lines.

I read Tom's Gato build and he too had removed weld lines.

He also put them back using baking soda and CA.

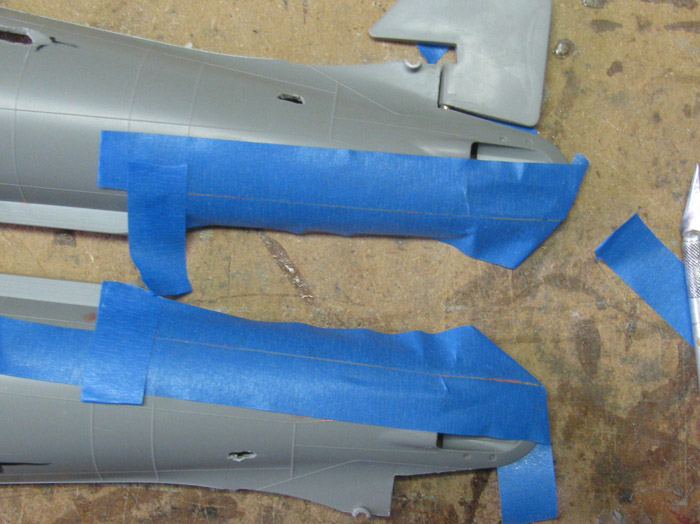

Here, I have taped off the replacement weld lines.

There is a small open space between the 2 tape pieces.

I put baking soda in the space.

Using thin CA, I covered the baking soda.

I let set while I moved on to other things.

To keep from jumping around too much, I will show the finished weld

lines after sanding using the tape for the thickness of the welding.

Thanks, Tom.

It worked really well.

The line replaces goes above the torpedo door.

Bottom hull, the line is below the bottom torpedo door..

Can see the line better here.

Center of bottom hull half.

Got a couple more lines to do.

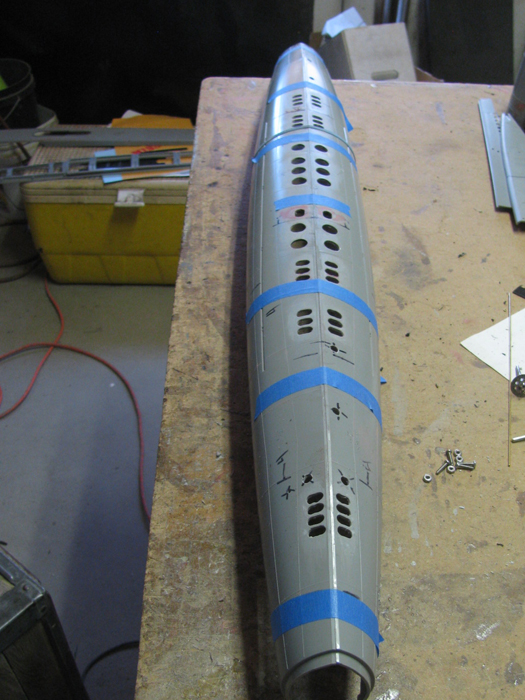

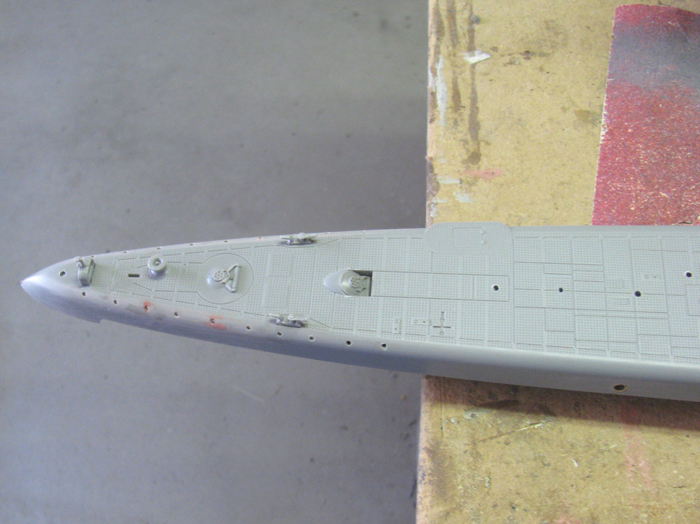

Time to join the 2 bow sections.

I decided to d this now because I tried to work on the bow planes lower,

rise mechanism and I could not hold it in place while trying to measure

for the control horns.

Looking at Tom's build, I saw I could join the bow sections and cut

the top out and would get access to work on the bow planes.

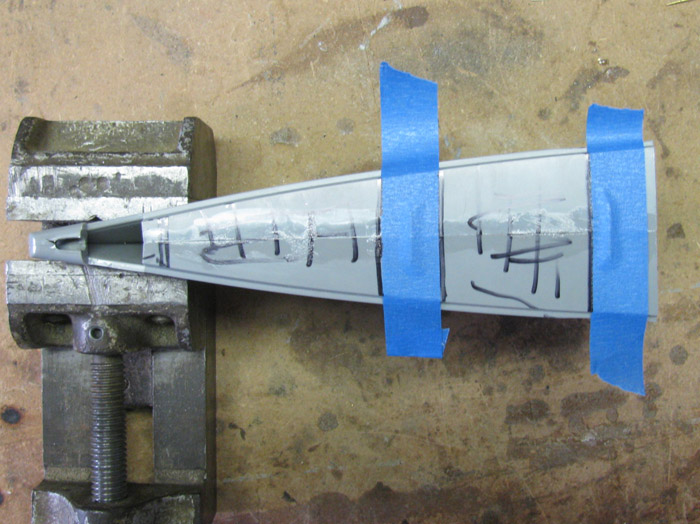

I had already glue the indexing pins to one side of the bow.

Applied glue to the pins and the edges.

Put the 2 halves together and taped to hold tight together.

I moved on to deck while the glue cured.

Back to the bow section.

I removed the tape and then marked the top of the bow section where

I wanted to remove plastic.

The vise is not tight but only holding the bow section for the photos.

Using the Dremel saw blade and a could of files, I ended up with the

opening in the bow section top.

Now I can reach in to fit the bow planes mechanism.

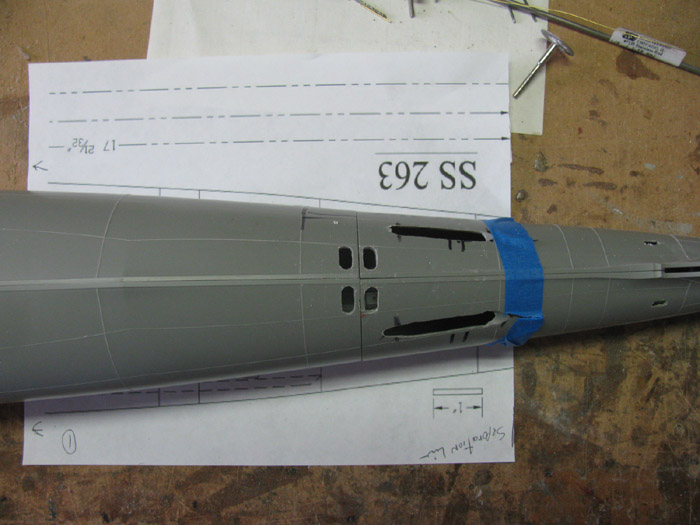

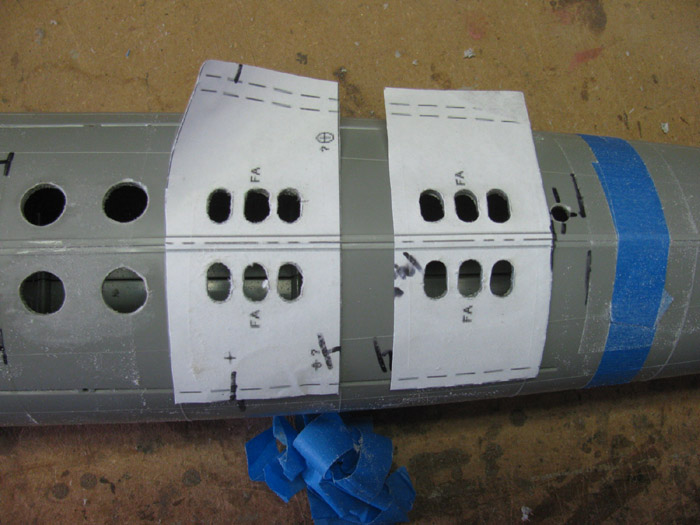

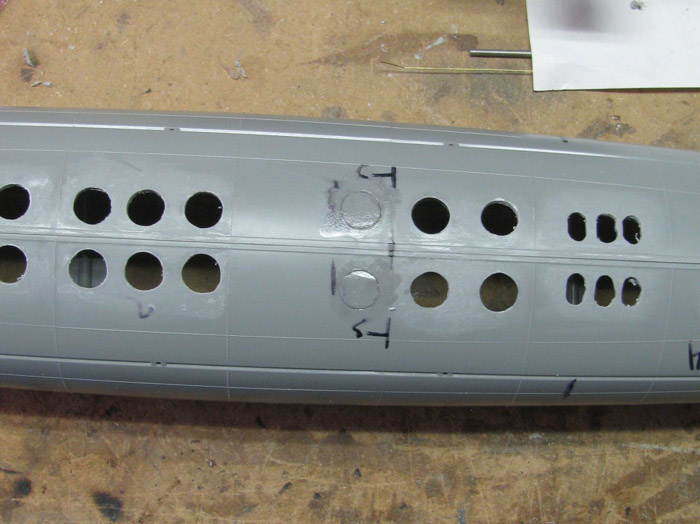

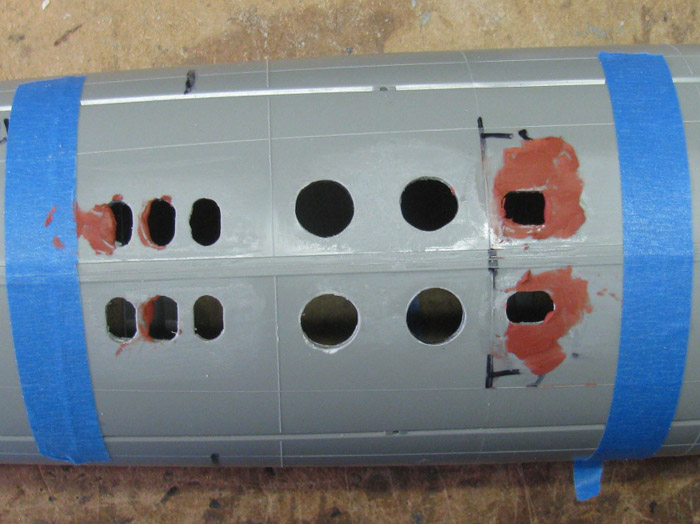

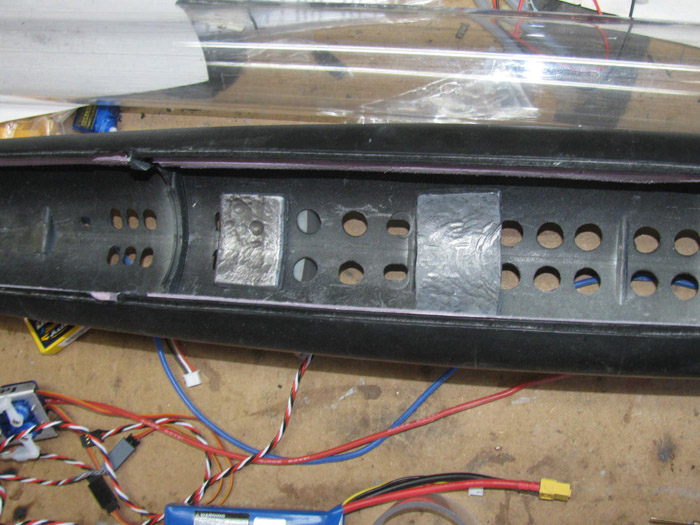

Before I glue the center hull sections together, I need to cut in all

the flood ports.

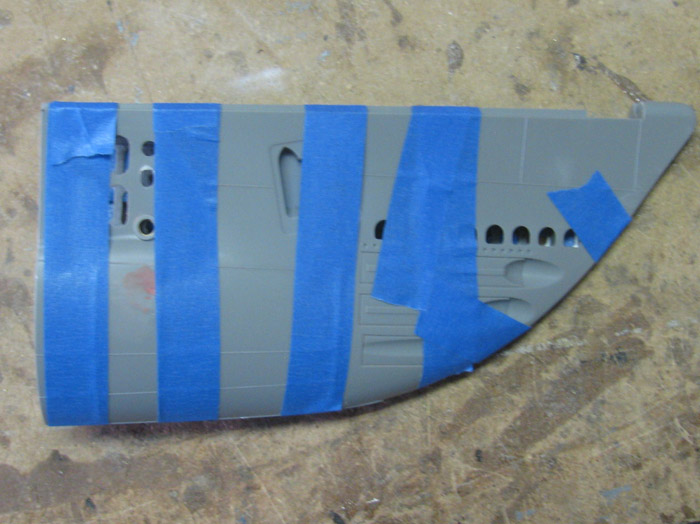

Here are 2 on the stern section and 2 on the center hull section.

Marked and drilled a location hole where all the flood port opens are.

Now comes the long job of cutting and filing all those holes.

Tom, I think I am going to use your "Milk" trick to put the flood holes

templates on the hull.

=============

Later in the day.

I have done 1 more weld line on each stern half.

1 more to go that is about 1/2" long.

I have drilled all the round flood holes.

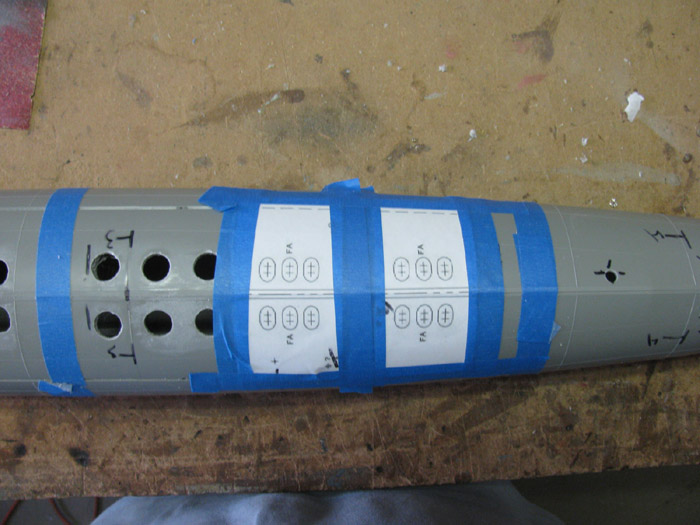

I have enlarged the oval holes.

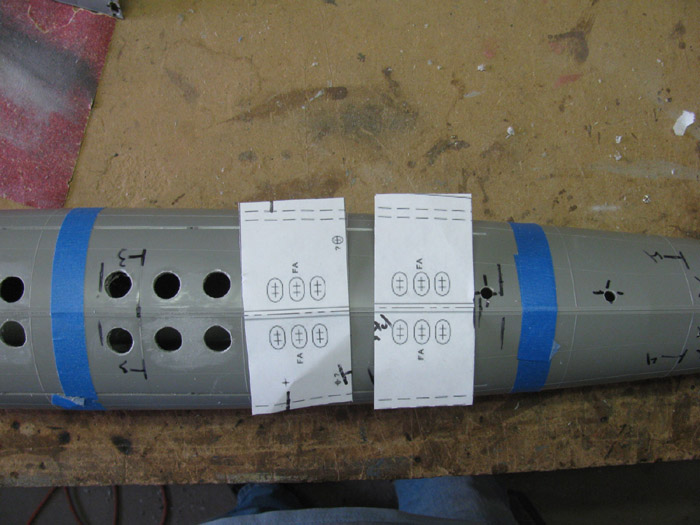

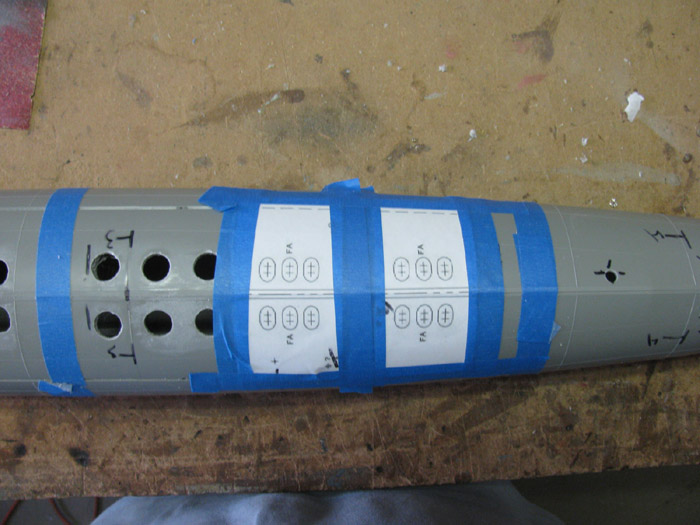

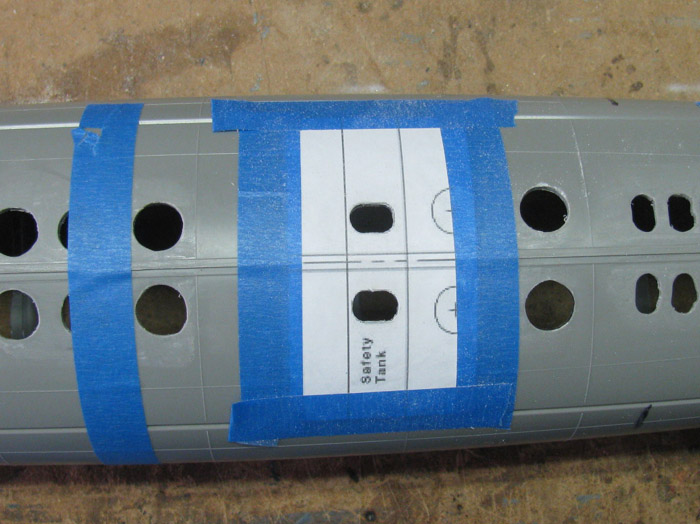

I have laid out the paper templates of the flood holes from the stern

joint seam going forward.

I have cut them in to small 3 or 6 holes per sheet so they lay flat

on the hull and not buckled.

I have built the conning tower big gun.

Not sure if I will build the small machine gun or run as if it was

in the stowed locker.

Things are going along fine.

I am building small parts and assemblies and not looking at the big

picture except to see where I should go next in the sequence.

I can see washing the plastic parts and painting in the near future.

December 1st =================================================

Got up and felt good.

So, I will attack the flood holes.

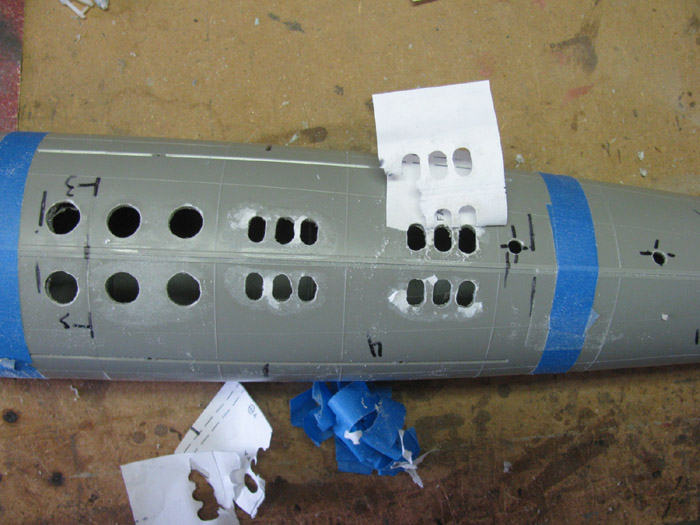

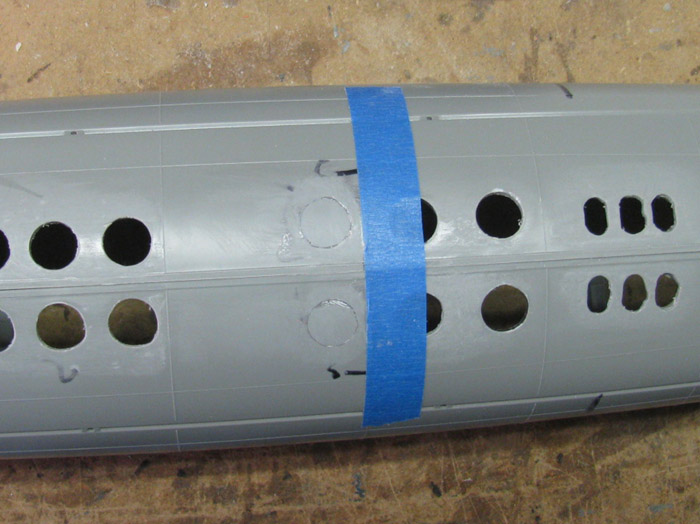

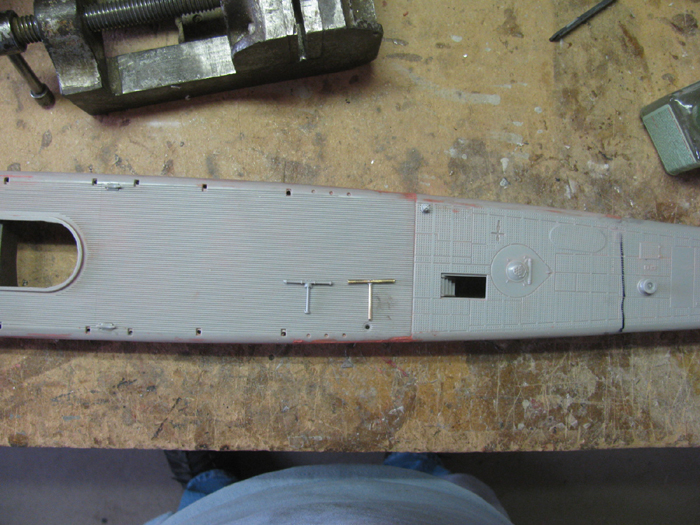

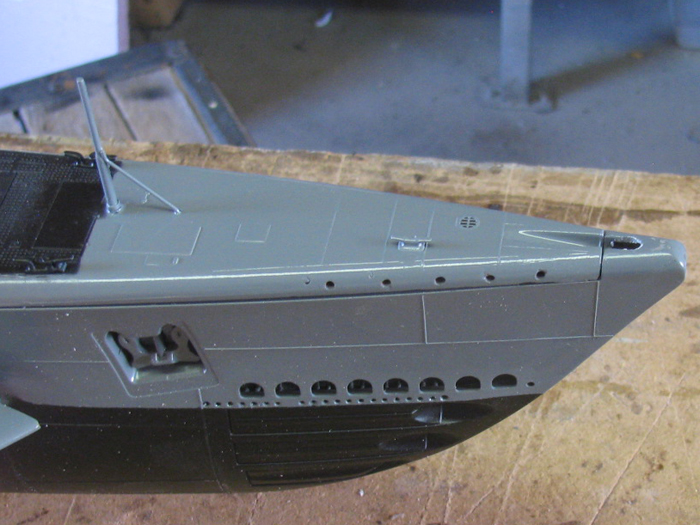

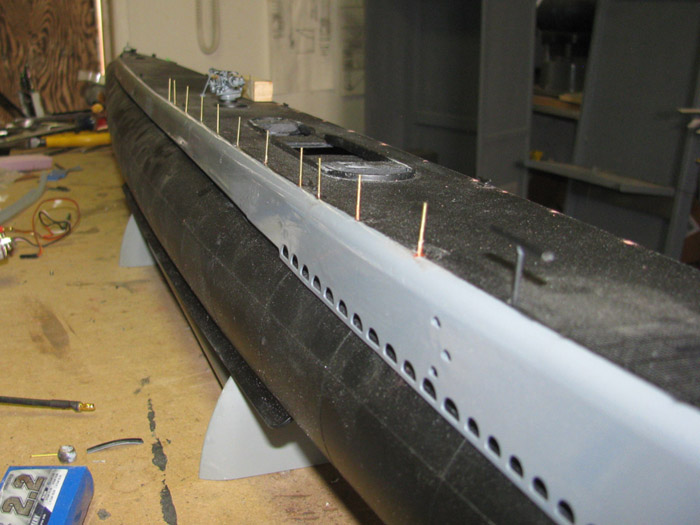

Here you can see I am moving right along.

Before I finish, I will try to explain how I did this.

Tom's build said something about using Milk to hold the paper pattern

on the hull but also said it did not do well..

He mentioned a few other tried that did about the same.

Having thought about it, I thought I would try using the method I use

to make frames and other plastic parts.

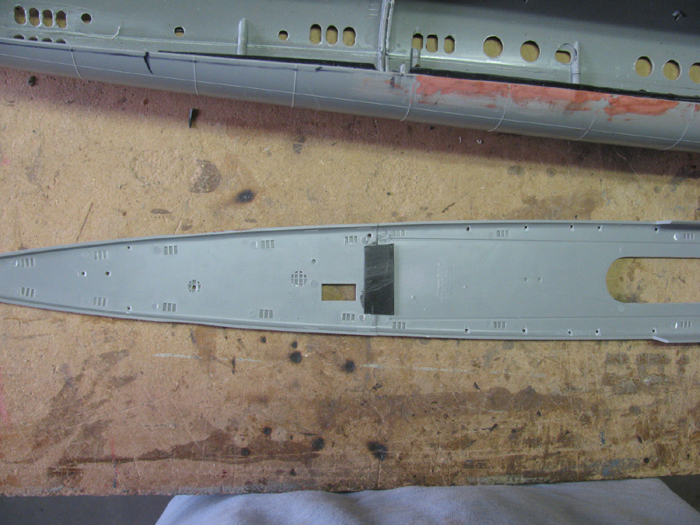

I got the middle deck and turned it upside down on the bench.

I took a scrape piece of paper and tested on the underside in case

it failed.

I could sand it off with out damaging the boat.

I printed out the flood hole pattern to scale.

Took 4 sheets of paper to get the overlap I need to align them.

I cut the paper using the weld lines marked on the image.

This is after laying the paper pattern on the hull to make sure which

weld lines to use.

I started at the stern break line.

Now to what I did.

I did 2 flood hole sections at a time.

Here I am placing the patterns on the hull to make sure where they

go.

Remember I drilled small holes using the full pattern. (I did not need

to do that)

Starting with one of the pattern pieces, I turn it up side down making

sure it is orientated correctly to the hull.

Have cement handy.

I wet the paper with cement and the lines on the pattern show through

so I can see where they are.

Wet the pattern, covering the lines of the holes going about 1/4" outside

the lines.

After covering all the lines, I do a quick covering again to make it

wet.

The cement soaks in fast.

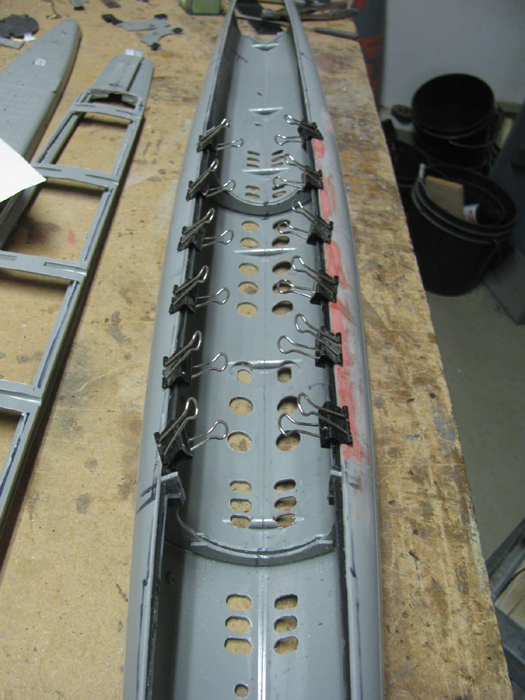

Once the second coat is on, lift the paper and place it on the hull

with the cement down and in contact with the hull.

Line it up with the keel center line.

Using my finger nail, I press the paper in tight against the keel.

Press the paper down on the hull and rub the paper making it warm.

Tape down all 4 sides and rub paper again to make sure it does not

move.

Do the same for the second piece.

Let sit for 15 to 30 minutes.

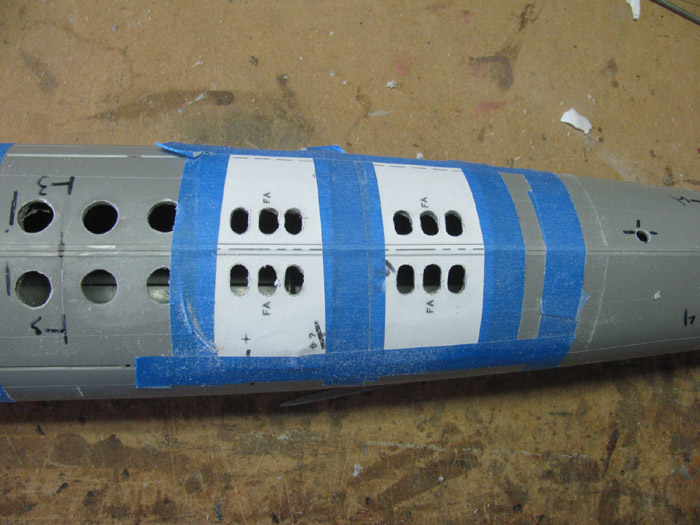

Using my Dremel with a 1/8" bit, I drill in to the hull and then route

out the plastic almost to the line.

I will use a couple of files to finish to the line.

I do not use the roto cutter.

Not enough control.

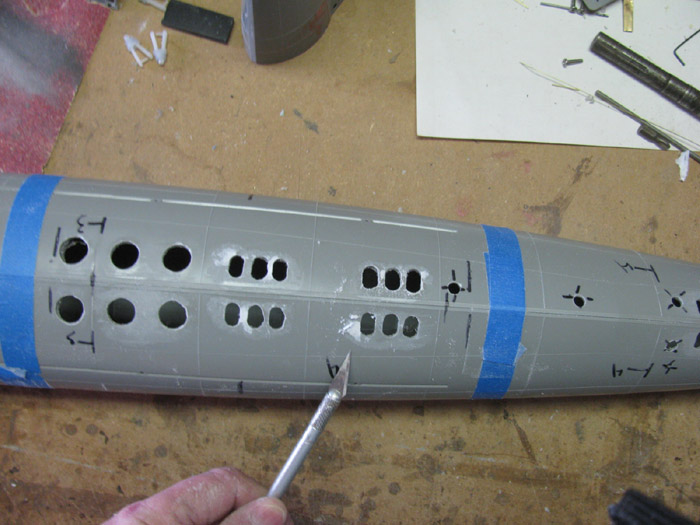

This is after the filing and deburring.

Remove the tape.

Remove the paper.

Pull the paper tight way from the holes and lift gently.

It will most likely break at the mid point.

Lift from the other side.

You can pick the little pieces of paper off with your fingers.

After removing the paper with my fingers, I used an Exacto knife to

scrape any remain paper off.

Sand with wet/dry sand paper to clean the rest off (180 grit is what

is on my beach. It is well used)

With the flood holes done, it's time to get serious.

Cut the top of the hull out.

This is were I stopped.

Fingers where cramping up.

Can not afford mistakes.

I real need to look at some other builds to see where they did the

cutting.

December 2nd =================================================

Today has turned out to be one of those jumping around days.

My plan for today was more plastic holes in the deck.

Found some close up photos showing the layout of the holes at the deck

stern.

But when I first got up, I started having thoughts.

So the plan changed.

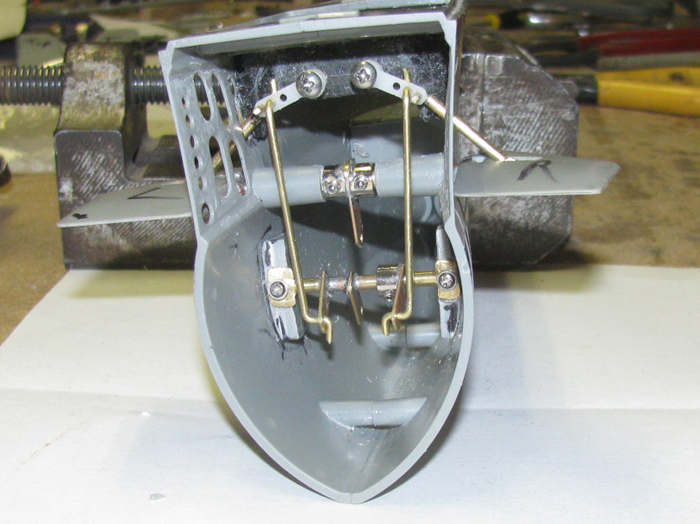

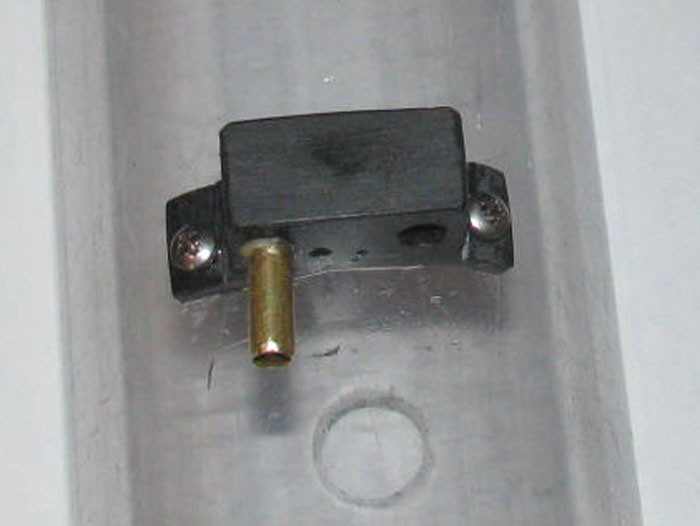

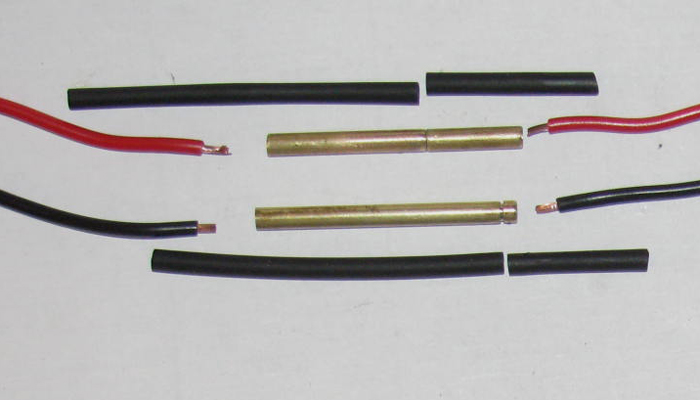

I picked some small pieces of tubing.

3 sizes.

This will be part of the bow planes operating system.

Not the bow planes them self but more linkage to get to the bow planes.

This idea came from looking a Darrin's big sub about a year or so ago.

(most likely longer)

What this is is to make it easier to get to the linkage for adjusting

and setup.

Some measuring and cutting.

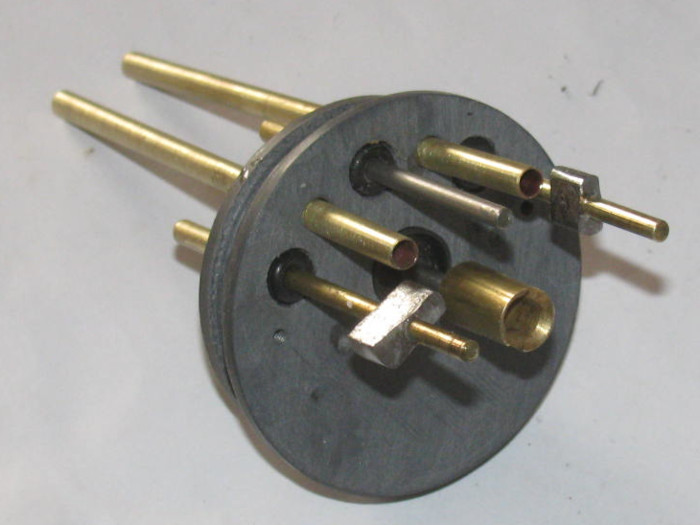

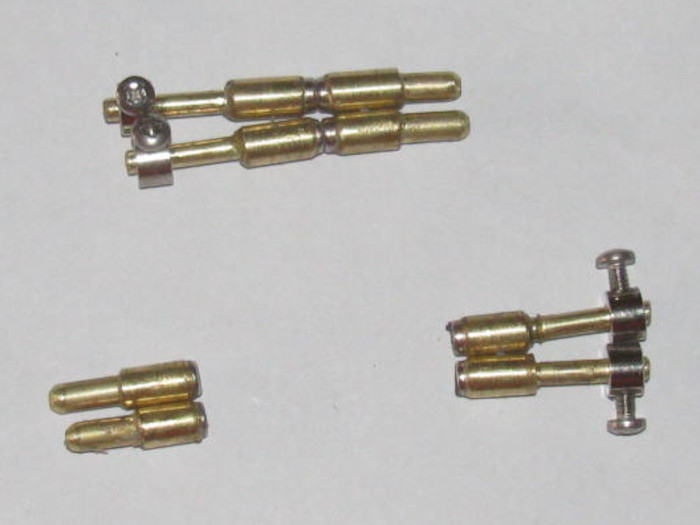

9 brass parts. (there are 2 plastic parts I have not made yet.

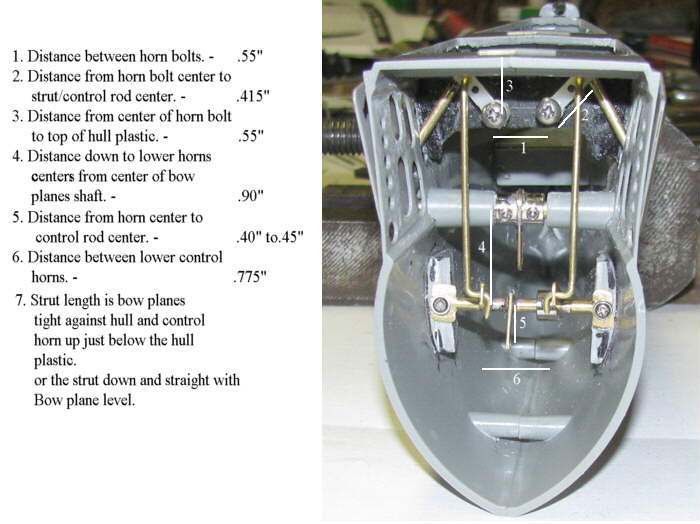

Top are 2 hinge peg brackets.

Next is a single long tube which will be the hinge pin.

2 short tubes go over the hinge pin and will rotate.

These will have the control rod horns soldered to them. (once

I start installing it all and get the correct angles)

4 flatten brass tubes to make the horns. (already drilled)

All the parts assemble to get a look. (dry fit)

More work needs to be done after the bow planes mechanism is installed

in the bow.

This unit will be low in the hull below the bow planes.

The horns where left long for now.

1 horn will raise and lower the planes and 1 will rotate the bow planes

for dive and rise.

The unit is upside down on the table.

The end brackets will be screwed with 1 screw each side on to plastic

blocks so I can remove the unit to work on it out of the boat.

Time to jump.

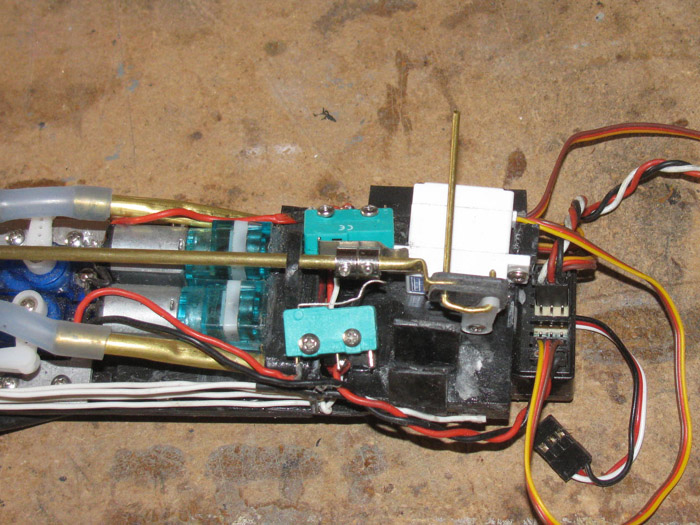

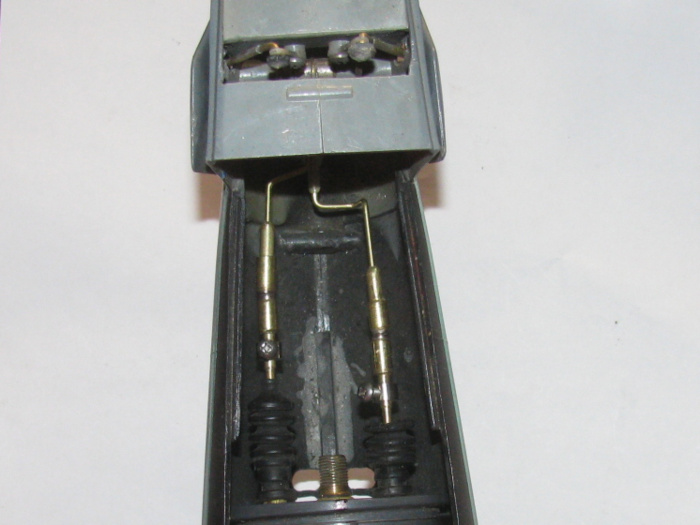

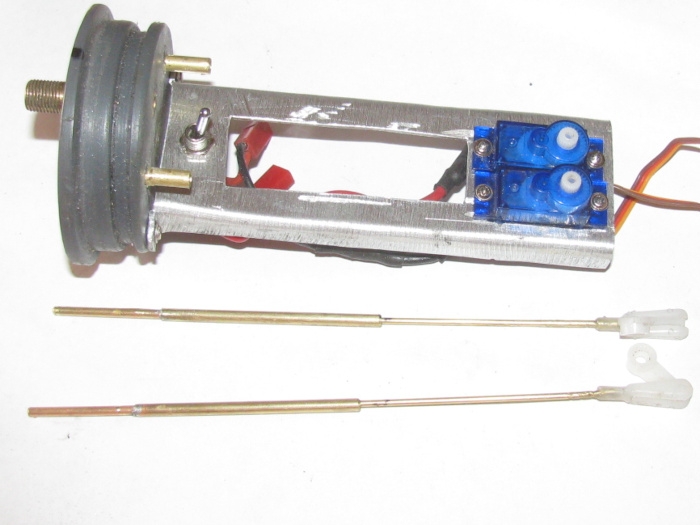

Made up the control rods for the rudder and stern planes.

I have an allen wrench mounted on a length of brass tubing to reach

in the stern.

But I think I can reach the nylon clevis to open it to remove the control

rod. (?? 2 options))

I did turn the planes wheel collar facing the back and I can reach

it through the torpedo tube opening.

Turns out, I can not use the 4 torpedo tube doors.

They interfere with the rudder horn.

Held the parts in place and worked the control rods to check clearances

and how much movement I have.

Rudder all the way to touching the planes.

The planes have about 30 degrees down and about 35 degree up. (more

than enough)

==========

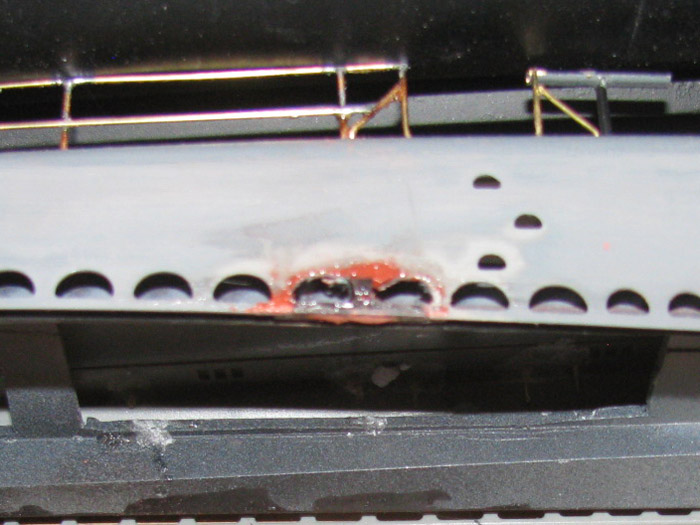

Looking over the flood holes, I see I made a mistake.

I made 2 large holes where there should have been 2 small holes.

In the following photo, there is a number 3 on the hull between 2 lines.

That hole should be the size of the paper holes but turned 90 degrees.

I will have to fix that.

Fill the hole and make new small holes. probably make the holes in

the repair plastic first.

==================

Jump, again.

Held the stern against the middle hull to see how the propeller shaft

strut and tube bearing sit.

The left side lined up to the strut and the hole in the hull.

Needed a plastic shim the thickness of the hull to hold the front end

of the through hull tube bear away from the inside hull so the middle hull

joint will fit under the bearing tube.

Tapes a piece of shaped plastic in the stern section where the joint

will be.

Taped the long tube in place and then lined up the rear tube bearing

to the stern planes using the propeller shaft as my guide.

I placed a flat piece of plastic on the stern plane holding it with

a spring clamp.

The propeller shaft rested on the plastic making the shaft inline with

the stern planes.

Need 4 hands to do this so help with tape and spring clamp did it.

Got my medium thick CA out and the kicker.

A drop on the rear strut at the hull where the strut goes through the

hull. KICKED IT.

Made sure the little plastic shim was still in place and I lined up

the long tube with the indexing marks I I put on the hull to get the end

in the right place and centers to the fore and aft lines.

Medium thick CA on a .030" wire and drug it along the tube/hull seam.

KICKED IT.

Made sure the propeller shaft turned freely. Yep.

Drooped a little CA on the opposite side of each joint and KICKED IT.

Removed propeller shaft. Only have 1 right now.

----

Did the other side the same way.

I had to break the long tube loose and line it up again.

It did not turn easily.

Line everything up again and a drop of CA.

Shaft turned nicely now.

CA the other side of the parts and You guessed it. KICKED IT.

The CA is to hold all the parts in place.

I will CA and baking soda the gaps, tomorrow.

Then I will finish by placing a plastic piece inside the hull that

will be a block with a hole in it for the tubing.

I have some old silk span that I will put a couple of layers over the

tube in the hull to make sure it holds.

Fill the outside with glaze and shape it to match the hull.

The propeller shafts line up to the center of the stern planes.

Once this is completed, I will measure the placement of the cylinder

to see if I need to cut some of the long tube off.

Maybe an inch but maybe not.

December 3rd =================================================

Photo of the repaired holes.

Sanded flush with hull.

Paper pattern in place and new holes cut in.

Time to do a little glazing.

This all that is needed.

Sanding tomorrow.

December 4th =================================================

Worked on the 2 stern sections.

Filed and sanded to get the through hull propeller shaft housing cleaned

up and the hull.

This took a while.

CA with baking soda is very hard material to get smooth and shaped.

Worked on the skag gap.

Placed a shaped piece of plastic in the slop so I and use it for a

retaining screw later.

Going to make the back half to the skag removable to pull the dive

planes out.

Opened up 1 rear torpedo door.

This will allow me to put the doors in the hull.

I can get to the allen screw on the rudder with a standard length wrench.

Now they need to be glazed to finish getting the shape right.

Sanded the repaired and flood holes.

Then applied plastic cement to harden it.

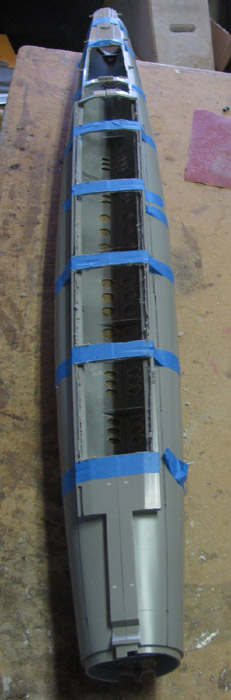

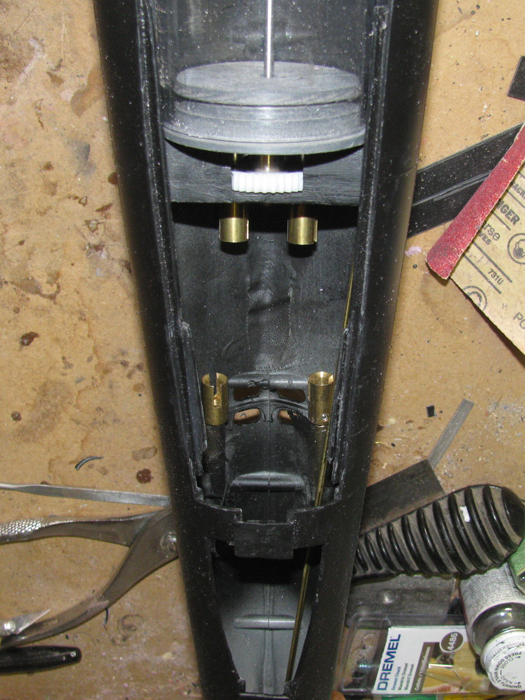

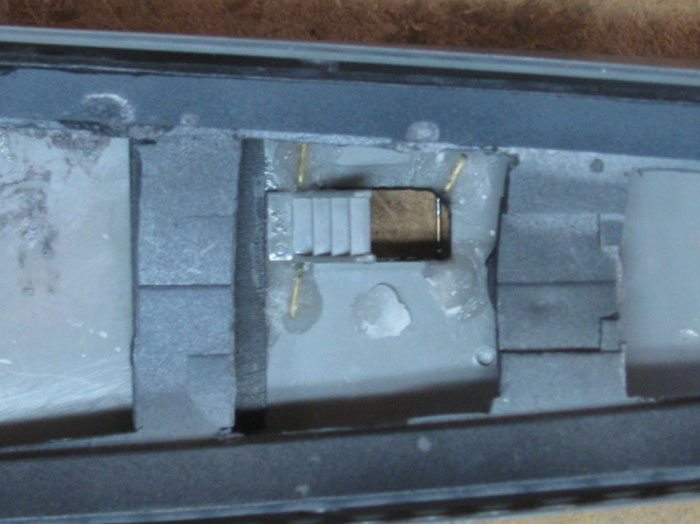

While I had the middle hull sections on the bench, I dropped the cylinder

in.

Something was not right.

I had cut the 2 frames to hold the cylinder just above the hull index

pins.

The cylinder is 29" long and with the frames on does not sit down low

enough in the hull.

Using just one hull half, I used scrap plastic to lift the cylinder

up.

I had a reference, from where I don't remember, that the cylinder would

sit about 10..5" back from the bow end.

Marked the inside of the hull and placed the cylinder at that mark.

I had to raise the cylinder up 3/16" higher than the indexing pins.

I files the 2 frames on the indies top so the cylinder would go up.

Measured down through the cuts in the top of the hull to get the cylinder

level in there.

Attached this slowly.

Once I got the cylinder to fit in the hull and level, I got measurements

to make new frame saddles inserts.

Here is 1 frame with 1 new saddle on one side and a second saddle for

the other side.

I doubled up the frames.

Did the same for the other frame.

These new saddles are just to support the bottom of the cylinder.

The cylinder fits and can be moved about 1" at the bow and about 1.5"

at the stern.

When I place it will depend on the linkage connections.

===================

Tomorrow, I may be able to put the stern section halves together.

December 5th =================================================

When I assembled the bow planes, I noticed the planes did not retract

up tight to the hull at the front edge.

At that time I decided to live with it.

Well, as time goes on and I am now working on the stern and bow to

get the control rods ion place and work smoothly, I find I can not live

with the bow planes not being tight.

I knew that a small angle was needed on the hinge to get this to happen.

I thought I had done this. ? ? ?

Reading Tom's Gato build he added a drawing showing how the angle should

be.

Got out to the shop and turned on the heat. (temperature in the shop

was 38 F)

Took a few minutes to get warm enough to work.

First, I was going to take on the dive planes.

I cut the front hinge off.

The one where you can see the hinge pin.

Removed all the plastic from the pin and then pulled the pin and strut

out of the bow plane.

Cleaned up the hinge pin of glue and plastic.

I put the planes back together and held it by hand.

Traced an outline around the plane and strut.

Remove the strut and turned it over.

Put it over the tracing and found I did have the angle when I built

it.

\I just happen to put it in reversed.

Did the same to the other bow plane.

Guess what.

I had reversed it as well.

Made 2 plastic pieces to cover the hinge pin.

Cemented the pin covers in place.

While these 2 parts cured, I started making parts for the retraction

mechanism.

Here the planes are seen with the pin caps and the start of parts for

the retract.

Bow planes now sit tight to the hull.

More work to be done on the retract mechanism.

It has warmed up in the shop, so I thought I would do some glazing on

the stern sections.

I glazed around the shaft bearing housings.

Now that I have done that, I took the stern sections in to the house

to cure.

December 8th =================================================

Filed and sanded final glazing.

I need to put the weld lines back on.

I test fit the stern to the main hull.

Then I test fit the cylinder in one half the hull and put the stern

on.

Looks like I need to cut about 3/4" off the propeller tubes.

This will leave room for the Dog Bone connectors.

Finished parts for the bow planes retract.

Here the planes are up.

Here the planes are out.

Testing shows it works smoothly and without binding. (yea)

The horns have over travel so there is plenty to work with when trimming.

The holes in the hull where the struts pass through were enlarged vertically.

The horns have 3 holes.

The farthest out is for the struts.

The other 2 so there is adjustment on the throw.

This devise will be mounted in the hull below the bow plane mechanism.

There will be a brass rod from each of the 2 bow plane horns down to

it's own brass horn.

There will ne only 1 brass horn going to the servo control rod.

This devise will mount using 2 small screws on to plastic blocks in

the hull.

I will use the hole in the bow planes that gives the best movement

with the most force.

I drilled more holes in the deck pieces.

Now have exhaust holes in the sides of the deck.

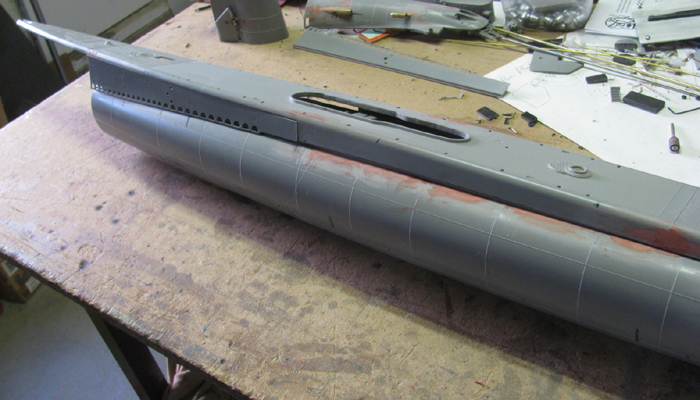

Test fit the cylinder in the hull with the stern and bow taped in place.

Looks like I may cut 1" off so there is room for the boot control rod

seals.

This still gives me 28".

December 9th =================================================

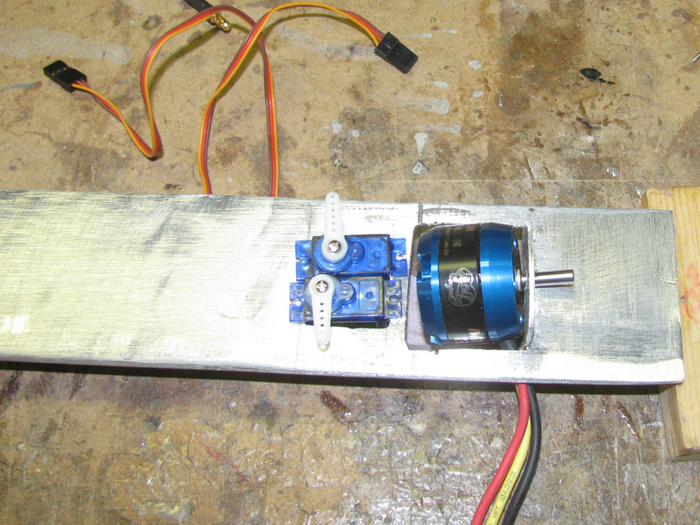

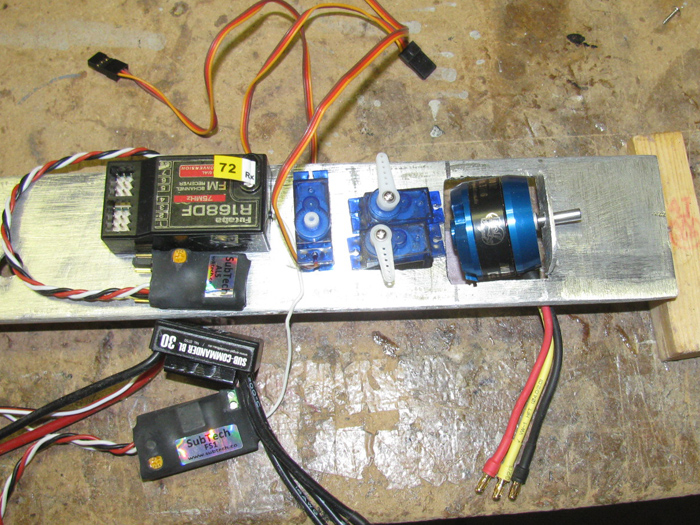

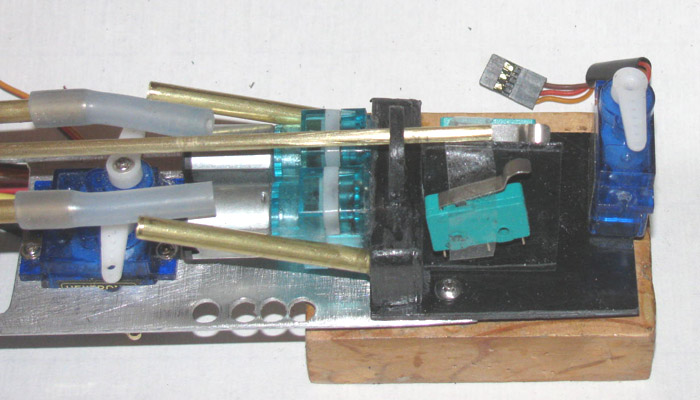

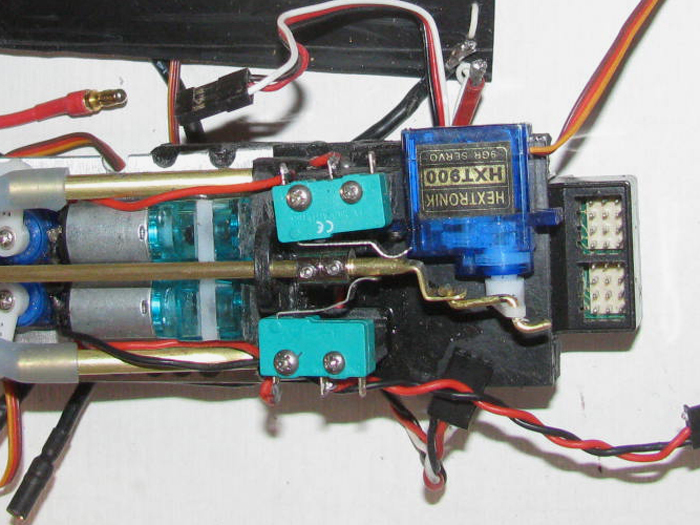

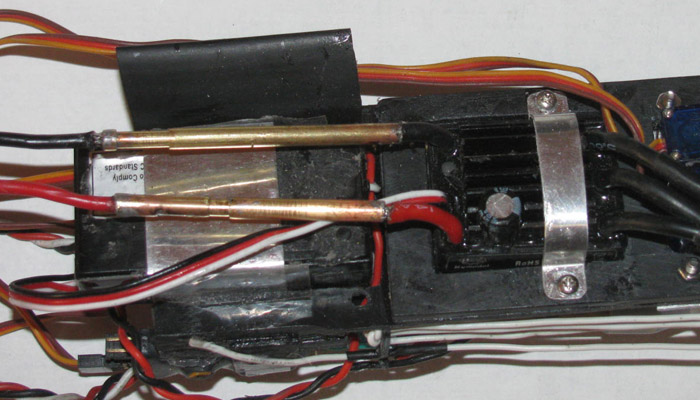

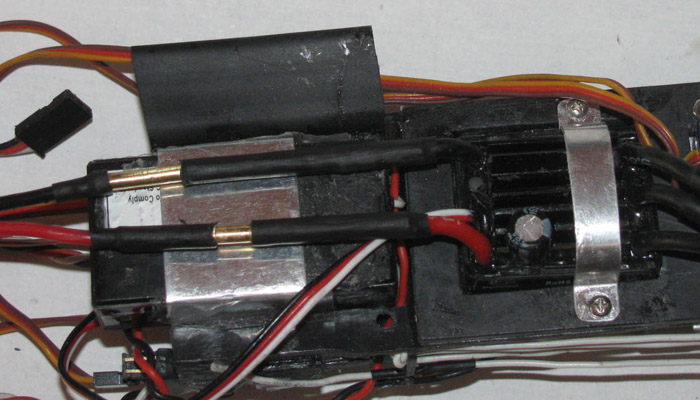

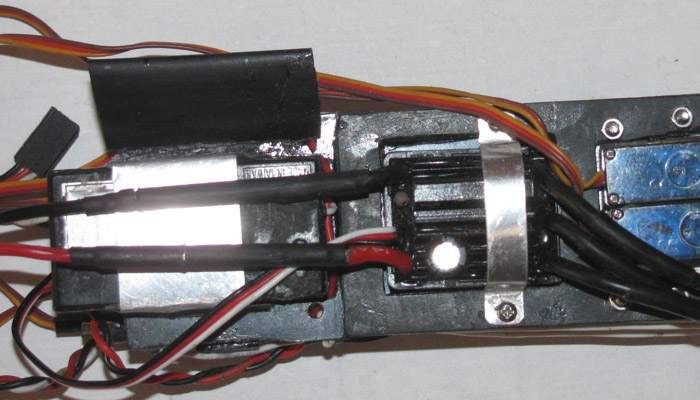

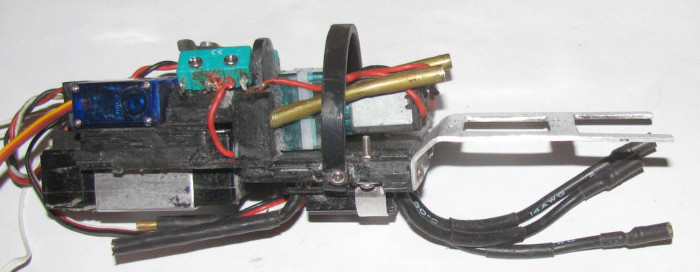

This assembly will be mounted under the bow planes retract mechanism.

The control rod in the photo will go back to the servo in the cylinder.

The other 2 horns go up to the bow planes retract horns.

The plastic end pieces will be bonded under the bow planes rotation

cross tube.

The 2 horns will reach forward past the rotation tube.

The location for the 2 plastic blocks has been made.

The plastic blocks have been installed and are currently curing.

While holding pressure on the blocks to get them to stay in place, I

was looking around and I need to clean off the bench.

It is so cluttered, I only have access to 1/4 of the table top.

I have the conning tower, 2 guns & mounts, all 3 pieces of the

deck, the box with parts and all the tools, glues, small clamps and parts

for the ALMA and another project.

I think a bit of clean up is called for before I can go on.

There is no room for the Skipjack which I need to make a small repair

to so the hull halves sit tight together.

Oh and I need to repair a window handle in my truck.

Not a big project.

Fitted the other side last year.

December 10th =================================================

Did not get much time in the shop.

Here is what I got done.

Bow planes mechanism completed.

There was some binding at first but I found it and changed the parts.

The 2 vertical rods where in front of the planes rotate shaft.

As the rods moved forward and aft, they hit the shaft as the rods reached

top and bottom of the throw.

Did some bending of the rods and finally gave up.

There was no way to adjust one or the other if the rods where not exact

to length.

Did some measuring and found I could run the rods to the back side of

the shaft.

and turn the lower horn assembly over making the horns move to the

back. Reference the hull. Back...Front)

Now the rods are straight and the rod on the right has a wheel collar

so I can adjust the plane to match the other one.

Planes up for surface running.

Planes down for dive.

I still need to work on the right plane as the silicone bushing is not

doing it's part.

Will need to make something new. to put pressure down on the hinge

pin.

Cut the propeller shaft housings off 3/4".

New brass tubing to size for shaft have been made and installed.

December 11th =================================================

I started the morning, making adjustments to the bow planes mechanism.

This took a couple of minutes.

A little trimming of the hull hole the strut passes through.

On to the stern sections.

After cutting the shaft tubes, I need to make new brass tubing pieces

to insert in to the large tube.

Got them in and then checked the shaft alignment through the 3 supports.

Requires some filing to get the new bearing to line up.

One side took just a little work.

The other took probably 20 minutes to get it lined up and smooth.

I like my propeller shafts to spin freely by hand.

I looked around and thought about cleaning up the bench.

Moves some tools to the right end of the table.

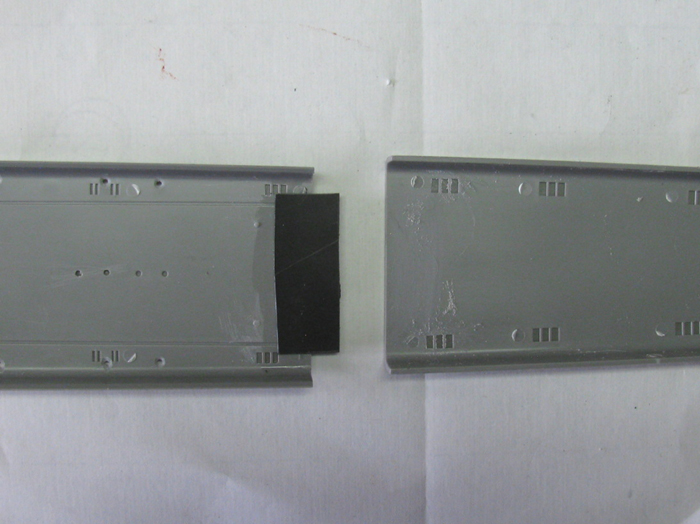

Then I could see, I had room to start assembling the deck sections.

To decide where to cut the hull, I need the 2 back sections of the

deck to do the measuring to see how the cylinder will fit thorough the

open after the cut.

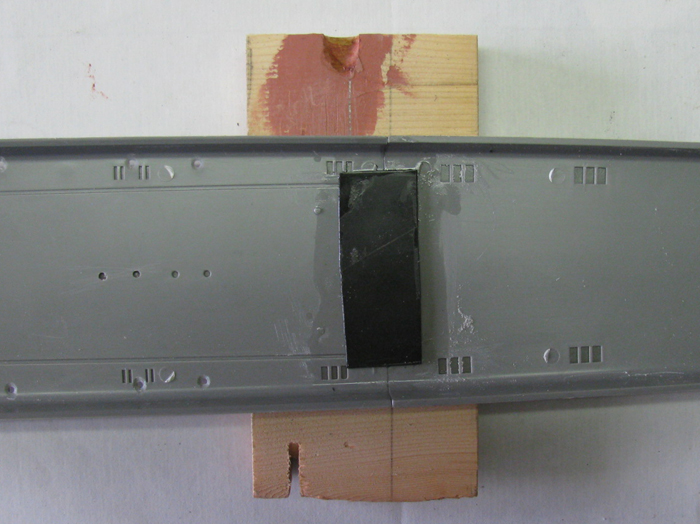

I started by putting a piece of sheet plastic on the under side of the

middle deck.

Let that cure for a few minutes.

Tom's build pointed out that the deck is not flat.

I placed the decks on the hull looked down the deck.

Yep there is a 1.4" rise from end to end of the rear 2 sections.

Using wooden blocks, I set up a surface to put the decks on while the

glue cures.

Glued and held down until the glue set.

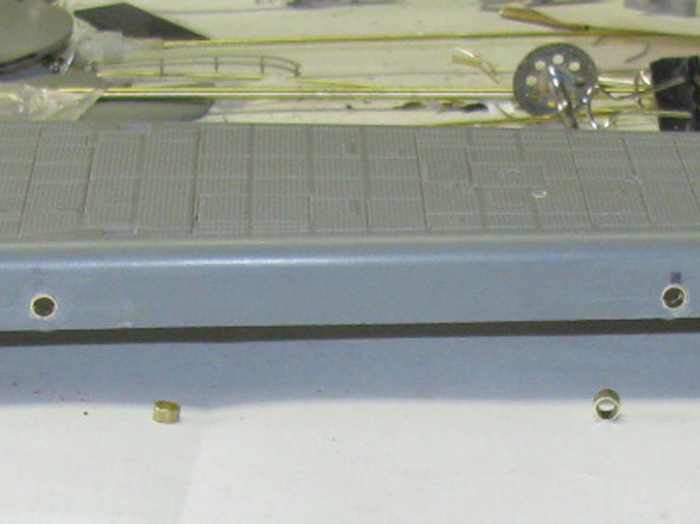

While the deck is off the hull, it is time to make the 4 exhaust ports

in the sides of the deck.

Here I have cut brass tubing to make the ports.

Drilled the holes to accept the brass tubing pieces.

2 ports in place.

Set the deck on to get a look.

WARNING ! ! !

Today is the day I have decided how I want to cut the hull for access.

I have decided to not cut the hull at the water

line which has been my plan since I started.

But looking at Tom's build I did some measuring

and found that his cut under the deck will work with the 2.5" WTC and the

length I want.

Here goes.

If you get squeamish when cutting in to the hull

full length, you may want to skip this section.

Taped the 2 hull halves together.

Set the deck in place.

Marked the outline of the deck with a black marker.

(wanted a big line to see where not to cut)

Using the diamond saw blade, I will cut 3/16"

above the marker line.

Look away .... I am going to cut this free hand.

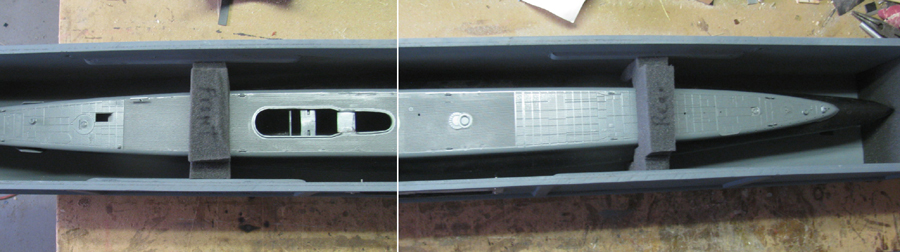

First photo the hull has been cut.

Second photo the top of the hull has bee removed.

Have not started removing the melted plastic

at this point.

Did a quick removal of the melted plastic but not to a finished edge.

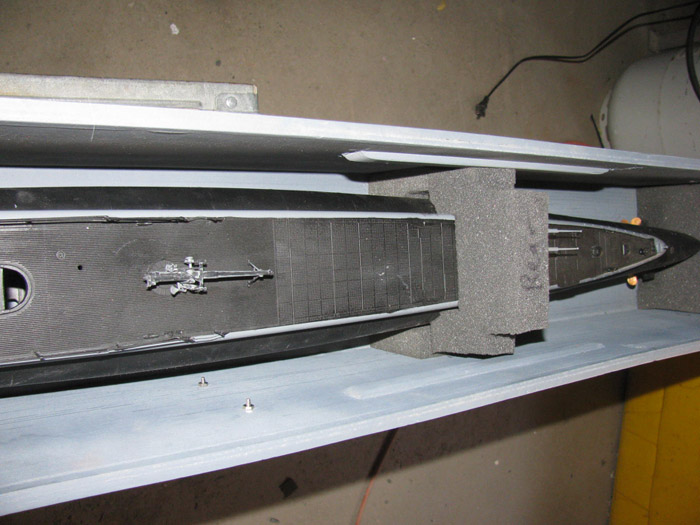

Dropped the WTC in to the lower hull halves.

At the bottom of the hull you can see the 2 marks I have made to indicate

where I want the front of WTC to sit between.

The opening is wide enough that the long cylinder drops right in.

Looks like there is room to add the end caps and still drop in.

I can cut 1" off the cylinder if needed.

Now for the time consuming part.

Clean up and make straight the cut edges.

Going to take my time and do short section and not try to do it all

at once.

I was out in the shop, again.

Thought I would get after the edges and see how much work I am in for.

Got my favorite wooden sanding block and wrapped it with 80 grit sand

paper.

Not to worry, my 80 grit sand paper is well used and is more like 200

grit.

There is one edge that is still in good shape.

I sighted down the cut edge to look for high spots.

Just a few.

These I went after with the Dremel and a 1/4" sanding drum.

Before the sanding block., I cut all the melted plastic off and hit

all with a file.

Now the sanding block.

I started at 12:55pm.

This went a lot faster than I thought it would.

Not only did I get the 2 hull pieces sanded.

I also got the 2 upper hull pieces sanded.

Once I was happy with it, though there could be more sanding after the

hull halves are joined, I joined the 2 upper halves together.

This is how I left it when I closed up the shop.

December 12th =================================================

Sanded the glazed areas down to a smooth hull.

I can see a few low spots.

Filled the again and set aside to cure.

Well, it happened again.

Was looking at the bow and saw where I could make a little change and

get more advantage out of the retract control rod.

Disassembled the parts after making a mark on each control rod about

1/4" back from the Z bend.

Cut the Z bend off and made a couple of small parts.

Using brass tubing that the 1/16" brass rod will go in, I flattened

the end.

Punched it and drilled a 1/16" hole in the flattened area.

In the photo below you can see the part at the top places over the

strut end sticking through the horn.

This moved the control rod out 1 more hole.

Soldered the new end to the control rod.

Made the second one the same. Almost. Little difference in length but

a small bind in the rod fixed that.

Planes up.

Planes down.

I may remake the lower horn assembly.

I may make the horns a little longer for more throw.

I measured everything and now to make a drawing.

I may enlarge the photo and draw lines on it and label them with a

corresponding list of parts and dimensions.

December 13th =================================================

The time has come to join the two hull halves together.

To get the upper deck mounted requires the lower hull to be complete.

Got to get the cylinder saddles cut and in place.

The deck needs tabs to hold it up once the saddles are cut.

Installed the 2 frames to one side.

Put the cement bond to each side and then put them together.

Tape to hold tight while holding by hand to squeeze the parts together

watching he seams for the cement lifting up.

Once the cement stops squeezing out, I can let go of the parts.

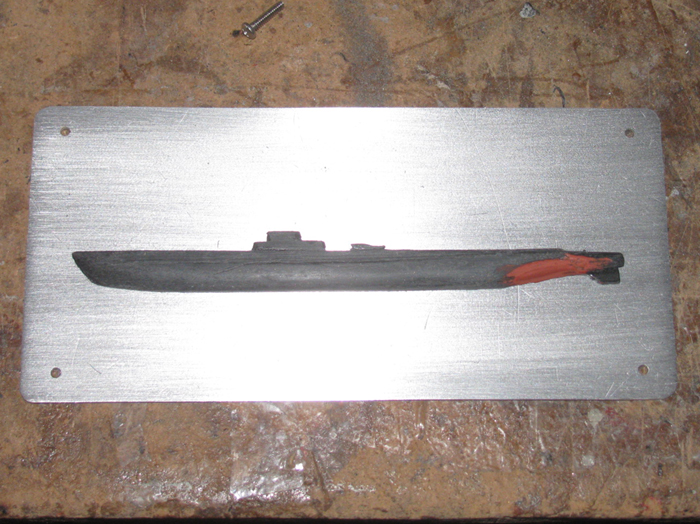

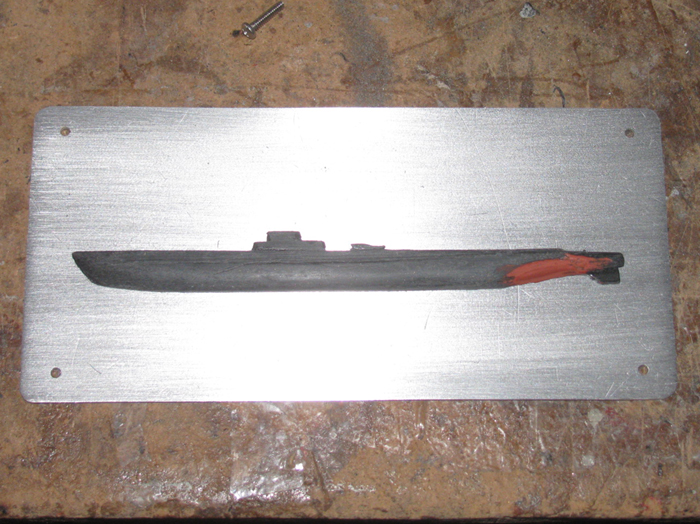

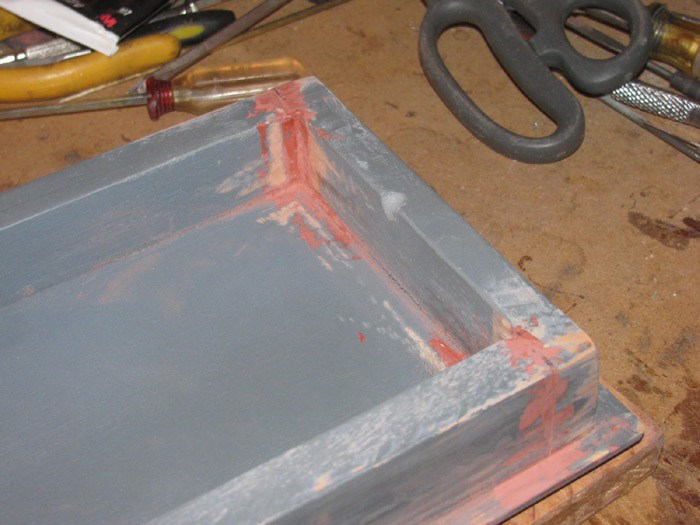

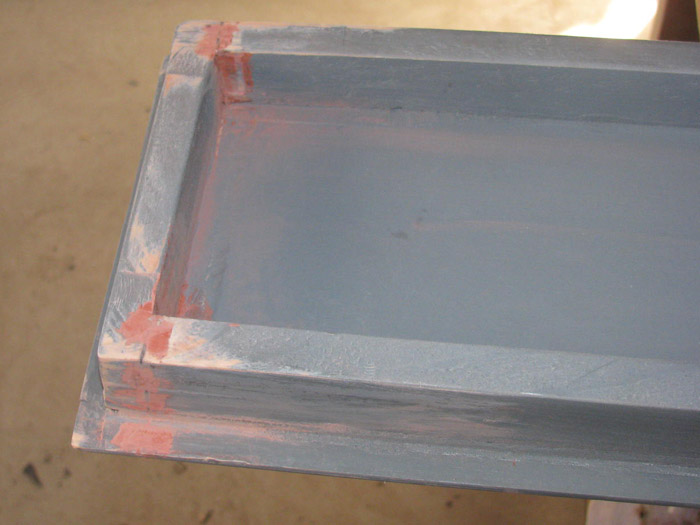

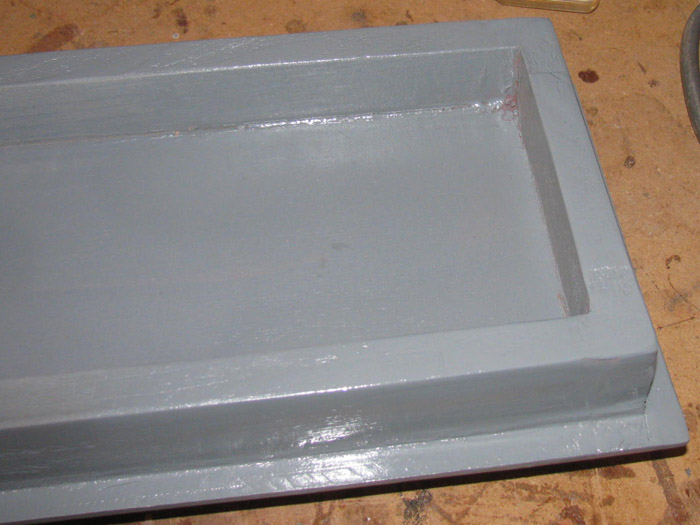

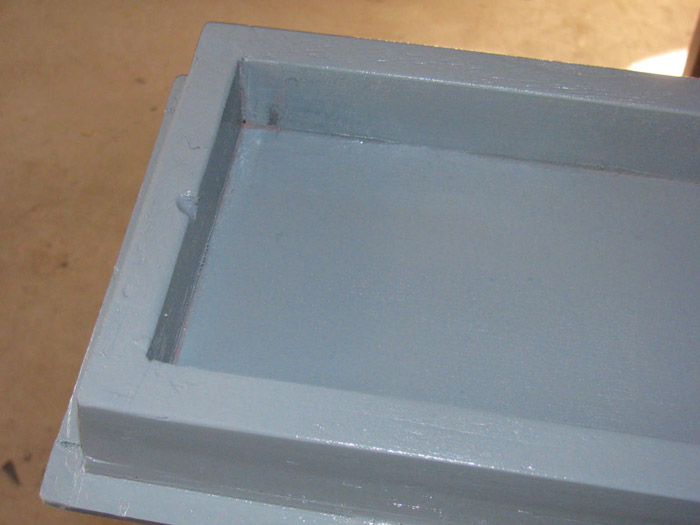

While in the shop, I thought I would work on the transportation box

emblem.

Basic hull shaped and glazed to correct a gouge.

When I was making these for the other boats, I made extra aluminum plates.

Once I get the hull glaze sanded out, I will mount the hull on the plate.

Then I can start making some of the parts that go on top of the conning

tower.

==================

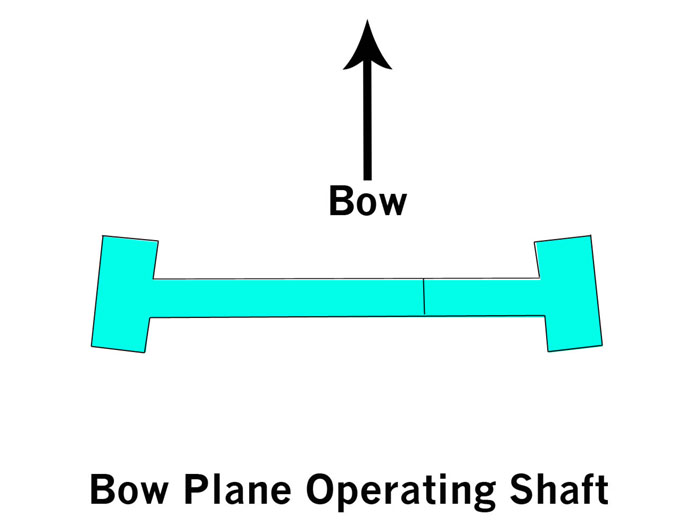

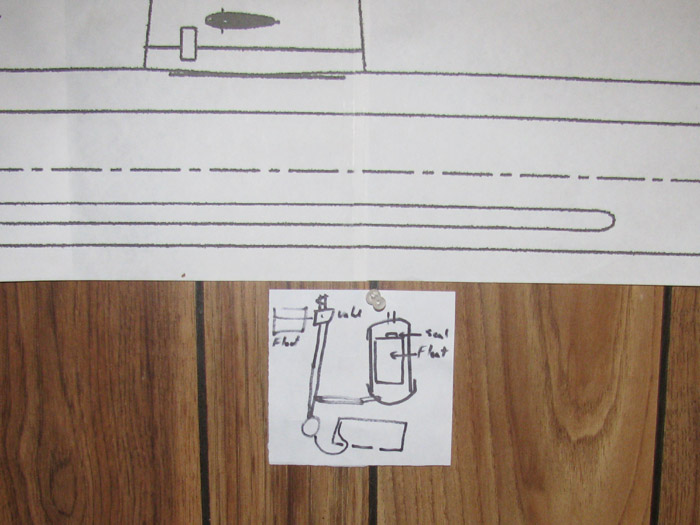

Here are the number my Bow Planes retract mechanism.

Finished out my day cutting the 2 frames and making index blocks to

hold the deck under frame at the correct height.

Here you can see 2 plastic blocks on the front frame.

The placement was decided after holding the cut frame piece in place

and seeing where it might work with the blocks on the cut frame piece.

Showing the cut piece and it's block set in place.

The blocks are sized to fit through the hull open.

There is the cut piece in place on the deck support unit for a look.

More to do on the blocks before cementing them in place.

I test fit the cylinder.

I had to spread the hull about 3/16" at the front.

Other than that, it dropped right in.

December 14th =================================================

Have things to do in town but I got in to the shop for 30 minutes.

What I did was make the edge for the deck frame to sit on and not fall

in to the hull.

Measured the lower hull l opening and found the 2.5" width.

Marked the hull.

Cut some 3/8" wide plastic strips out of my 1/16" sheet.

In the photo the strips are in at the front and back.

They go front 1/8" to nothing where the 2.5" ends.

The center section is still clamped.

After doing this, I thought I would lay out the tools I use the most.

This will go with the post yesterday.

December 15th =================================================

Sanded the deck middle to stern section joint.

The joint on the sides where glazed yesterday.

Looks like a little more glazing to fill a low spot.

Assembled the deck and deck frame.

Set it in the hull to check for fit.

Looks good.

Test fit the bow section deck piece.

Tom mentions that the deck had a slight rise at the bow.

Looked for it and there it was.

Measured the rise.

Glued a piece of sheet plastic to the under side of the deck piece.

Let it cure.

Found some wooden blocks and small scrap pieces of plastic to level

the deck and make the needed rise for the bow.

Placed the deck upside down on the blocks and shims.

Cement on the extra plastic piece then the edges of the bow piece.

Put on the main deck and moved it to line everything up.

Put pressure on the seam and then steel blocks to hold it all down

to the shim blocks.

10 minutes later I turned the deck over.

Test fit the deck to the deck frame.

Sat it all on the hull and found that when I put the 2 deck sides at

the bow on, I need to make sure I have the deck all the way back to the

hatch stop at the stern or the sides will not fit the alignment pins.

Took it all apart.

Glazed the low spots on the stern seam.

Brought the Flat Black paint in to the house to warm it.

On to washing the deck frame which will get Flat Black on the hull

shaped areas.

The painting has started.

Made a mistake.

I should have put tape on top of the flat areas where the deck will

be bonded to the frame.

Now I will have to clean the paint off. oops!

The day is not over and I have done a little more.

I put a few more parts on the conning tower.

Built the kit stand because the hull keeps rolling on me while I try

working on it.

Cleaned the paint off the deck frame where I need to apply cement.

And yes, I mounted the deck to the deck frame.

The deck side is not cemented. I used it to get the frame and deck in

the correct spot.

This will make the side panel tight to the deck.

Before I bonded the deck to the frame, I again put wooden blocks and

plastic shims to get the correct curve in the deck. (or close to it)

The deck is not flat.

December 16th =================================================

Later start this morning.

First thing I did was do some sanding on glazing on the bow.

Just things I didn't see earlier.

Test fit and found the hull was to narrow at the bow hull joint.

Make a plastic spreader bar.

A length of plastic longer than the gap across the hull.

Then added another strip of plastic that was a little shorted.

This allowed me to set the bar across the hull and the long piece set

on the hull and the shorter piece would push the hull sides out as I move

the bar forward.

You can see it about 1/2" back from the bow section on top of the hull.

Applied the cement.

Put the bow on and centered the bottom center line.

Moved the spreader bar forward and twisted slightly on the bow to get

the bow to self center.

Before I put the bow on, I made sure everything that needed to be in

the bow was there.

Don't want to have to work down in such a small space.

Moved on to the stern.

After yesterday's mess while making vent holes, I glazes some of the

holes that didn't look like they were right.

I hand drilled a few hole again.

Glazed the slow spots I could see.

Set the parts aside to cure.

Not quite ready to instal stern section to hull.

Note: I put the small holes between the torpedo tubes on both the stern

and bow.

I did not have a drill the right size.

I did have some piano wire that was close. (.028")

Cut a 3/4" piece and put in the Dremel.

I left the end of the wire with the cut edge.

I drilled 2 holes at a time and removed the melted plastic from the

wire.

I have used wire to make holes on wood and plastic.

I have even used a sewing needle to make holes needed.

Installed the front side deck panels.

Bonded to the deck and not the bow section.

Will remove with the deck.

December 17th =================================================

Checked fit.

Glazed the deck side panel joint.

Back to working on the stern section.

Cleaned up the glazing where I had drilled holes.

Some had to be filled in and today I redrilled them.

Not perfect but much better.

Checked fit and installed the rudder and planes.

Cemented the 2 stern section halves together.

The propeller aft bearing strut was install.

It was cut in to 2 pieces to give access to the rudder.

Made a piece from plastic to put in the slot in the rudder capture piece.

I want to drill a hole doe a retaining screw.

This will give access to remove the rudder control rod and rudder.

Access to the Allen screw holding the rudder control arm is through

the top right torpedo tube door which was cut out.

I cut more plastic out of the top of the stern section that will be

under the deck.

I think I will be joining the hull with the stern today.

Going to give the stern cement time to cure before putting pressure

on it to spread the hull to fit the stern section.

==========================

I have made up my mind on what I will do with the stern.

I cut it at the front edge of the rudder. (it is cut in the photo)

Continuing the cut I made on the skag.

The cut piece lifted off.

Rudder and control rods set in place.

Make a new rudder shaft and control horn.

Measure the shaft before cutting so I can get the length correct when

I make the new one.

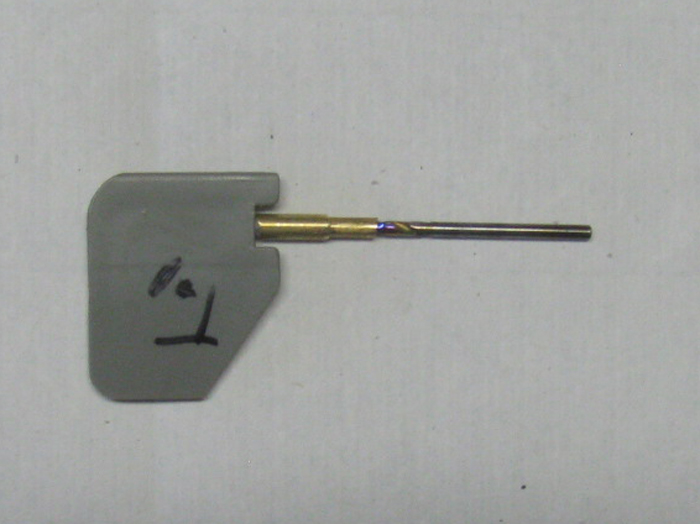

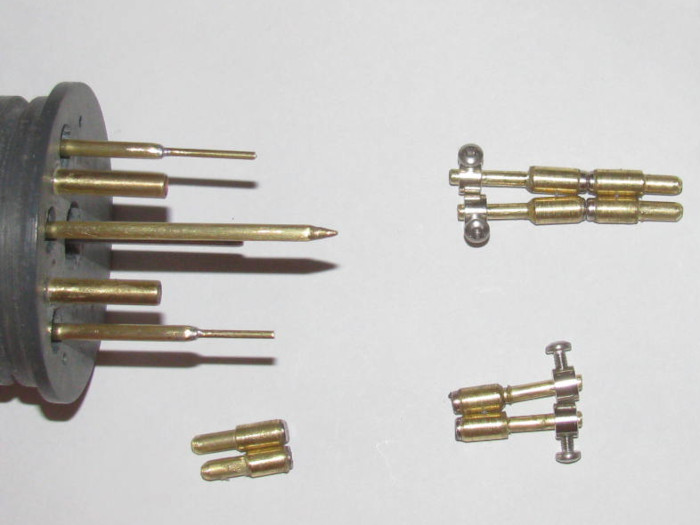

How I drill the shaft and keep it straight?

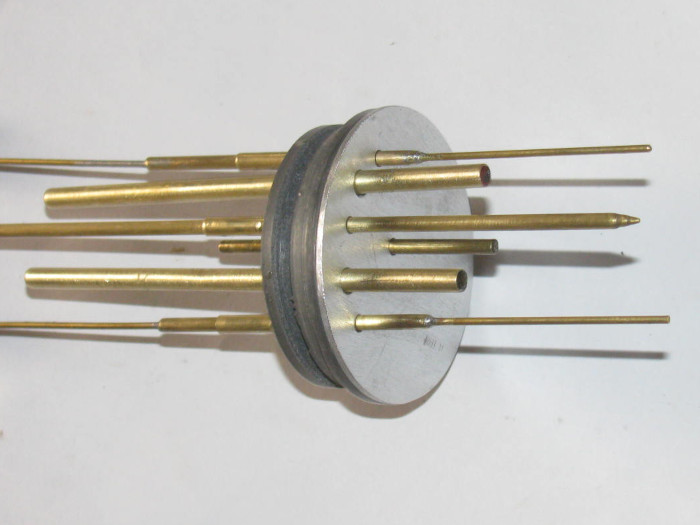

I cut some short pieces of brass tubing

One goes over the old shaft piece.

One goes inside the first piece which should be the diameter of the

old shaft.

The inside diameter is the brass tubing I will use as the new shaft.

Drill is size of new shaft to be used.

Slip the large brass tube over the plastic shaft.

Slip the next smaller brass tube in to the larger one.

The shaft size drill should fit in to the brass tubes.

Ready to go to the tool shed and use the drill press to drill the holes.

Go slow and pull the drill out often to get rid of the plastic on the

bit.

And remember there is about 1/4" of plastic before I get to the plane

itself.

Then I want about 1/2" into the planes.

(I did this for the rudder as well)

Test fitting the new shaft in to the planes.

I made a new shaft assembly and horn which is all soldered together.

{I need to straighten the control rod.)

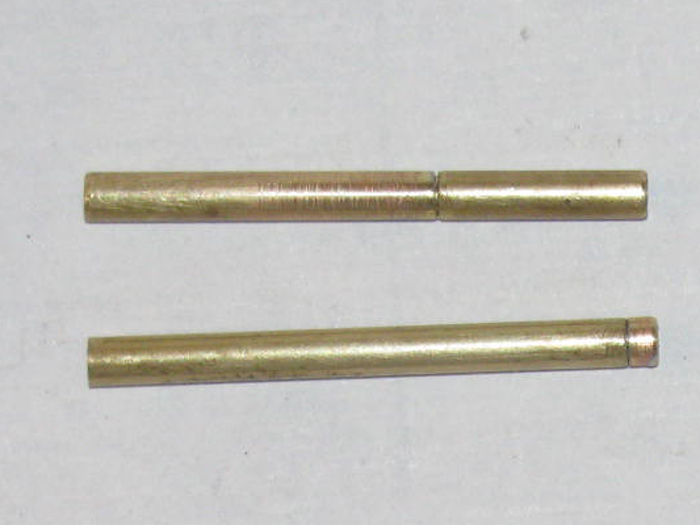

The brass tubes in this photo are not the same tube I used to drill

the holes.

The larger of the 2 tubes was 1/8" to fit the planes bracket on the

skag.

It was cut to the width the 2 planes where to be a part..

The second brass tube fits in side the 1/8" and is 1.25" long so there

is a minimum of 5/8" in each plane.

Control rod resoldered to make it straight.

Glue was put on the ends of the small tube and the tubes where pushed

in to the planes until they stopped.

Before I disassembled the old assembly, I marked the ends of each plane

to get the angle correct when rebuilding.

December 18th =================================================

I have attached the stern part that was cut out.

Using a long stainless screw from a bad micro servo, I drilled a hole

through the front torpedo vent hole.

You can see the head of the screw if you look closely.

It threads in t a plastic block I put on the bulkhead center plastic

that sticks past the opening in the hull.

Time to start installing the small detail parts.

Bilge keels.

Removed the cut section, I looked at the 2 cut edges.

The edge on the cut piece is straight.

The edge on the hull side is a bit uneven.

Just enough to see the seam cut after the screw is snagged up.

I glazed the edge on the hull and will sand it smooth after it cures.

I sanded the deck sides I glazed yesterday.

Found one small place to glaze again.

What to do?

I washed the rudder and planes preparing them for paint.

Might as well start putting the detail parts on the deck.

Some of the parts are very fragile.

Where I can, I will attempt to make the parts out of brass.

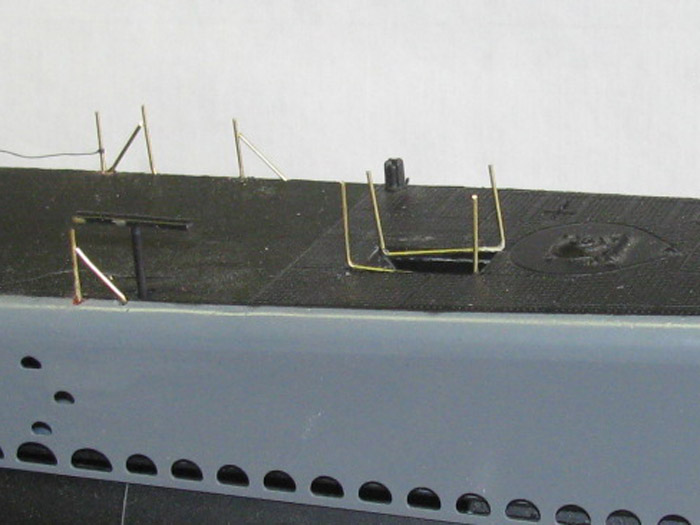

Here the sonar has been duplicated.

I [places a reinforcement plastic block under the deck to help support

the sonar mast.

2 parts.

1/16" brass rod for mast and 3/32" brass tubing flattened leaving in

an oval shape.

Drilled a hole through one side at the center for the rod to go through

but not all the way.

Soldered. DONE.

December 19th =================================================

Started this morning by Installing the sonar "T".

Made the pole that sits at the bow.

Sanding to fit the stern cut piece to the stern section.

I have a fit I like so it is time to join the stern section to the

main hull.

Find my spreader bar and get the cement.

Why two bottles of cement?

The round bottle is empty. (almost)

The square bottle is half full and the one I am suing.

The square bottle has a bush for pin point spot bonding.

The round bottle has a wide full brush for paint on cement.

I use the big brush.

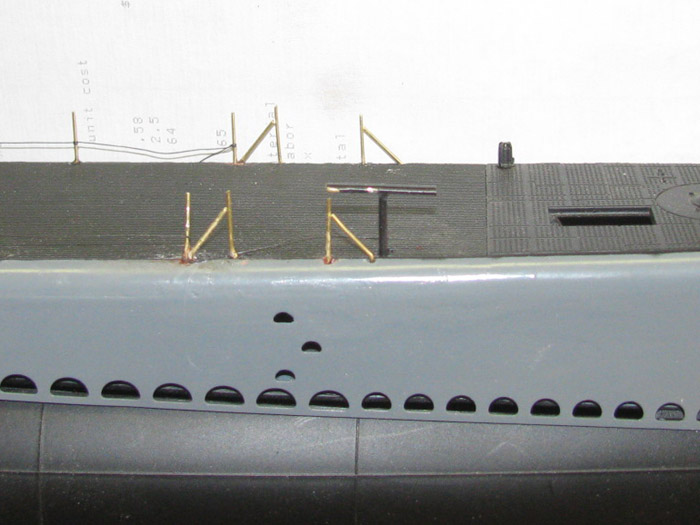

Filled the square holes in the deck where the lifeline stanchions go.

I thought I would try making a brass railing.

THis what I have so far.

Problem is, when I try to solder the low line on the stanchions, the

top rail comes off.

This may not be used.

However, I was reading the instructions to find the stanchions on the

parts trees and it says to use the supplied thread.

Thread?

Here is what I am thinking.

After finish sanding the deck to get the deck flat where I glazed the

stanchion holes, I could drill holes for the brass stanchion posts.

CA them in place from the under side.

The I could use the thread and CA it in place on top the stanchions

The the lower line.

Once I get the thread on, I will run a test.

Put 2 stanchions on a block of wood.

Put the thread between them.

Make sure the thread hangs correctly to represent cable.

Paint the stanchions and thread with the black the deck will get.

If that works then move on to the deck.

If not try again and CA the thread full length.

December 20th =================================================

Sanded the stanchion holes.

Sanded a few other spots.

Glazed those spots needing more.

Set the hull on it's stand and place the deck and conning tower in place

to get measurements to build the transportation box.

It works out that I can build a short box by taking the conning tower

off and placing it next to the hull at the front or back.

The conning tower is taller than the hull with the sonar on the bow

and pole at the stern.

Couple of days ago, I painted the stern planes and rudder.

December 22nd =================================================

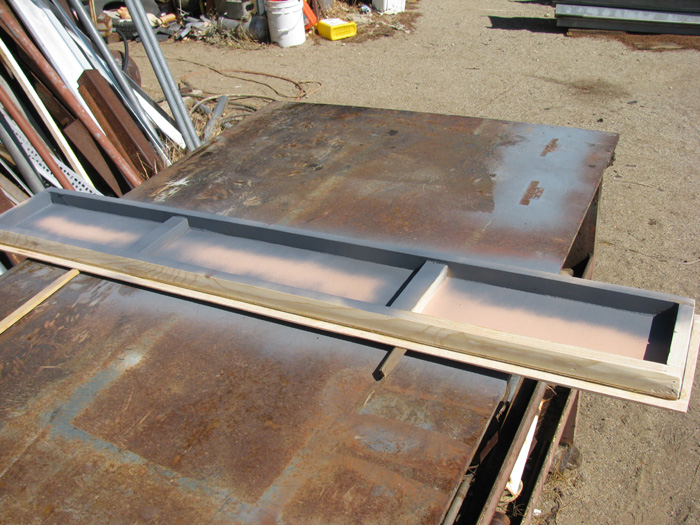

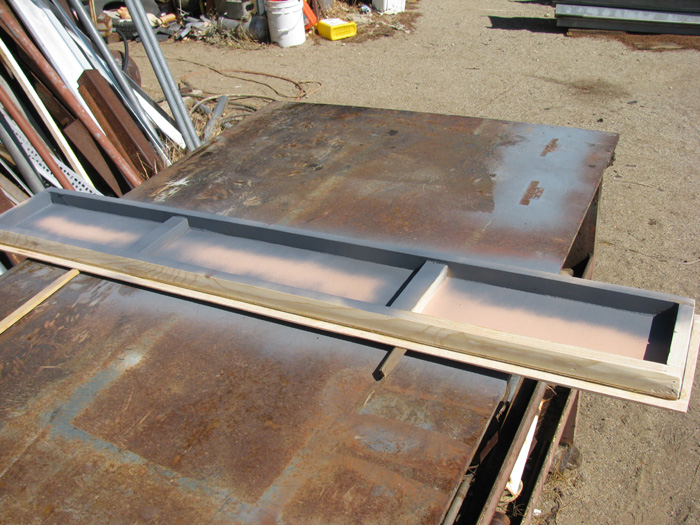

The building of the transportation box has started.

December 23rd =================================================

I got 1 hour in the shop.

I unclasped the box panel and trimmed the glue off.

I was still inside the window where the glue would cut easily.

In stops it was getting hard.

After trimming, I have a tool made from an old file I use to scrape

the excess glue off with.

It's like a 1/4" wide chisel.

After trimming it was time to put another wood trim strip on.

Used less glue this time hoping there is less to cut off later.

It wasn't that much but might well see if I can find the correct bead.

Got it glued and clamped on the bench again..

I use the outside bench because it is 1/2" thick steel and it is straight.

Any paint of glue that gets on it comes off with a 4" grinder.

Now in to the shop.

Looked at my 2 test pieces of plastic and epoxy.

Well, they are holding together so I guess I will do the hull.

Got the fiberglass strips in.

Not fun working this messy down in such a small opening.

I did find a box of latex gloss in a draw in the house.

I even used them.

Glad I did.

Got the fiberglass strips down on the seam.

I cut strips so I could skip the flood holes the best I could. There

will be some filing but only 2 or 3 partially covered.

For my first experience with epoxy, I think I did okay.

Got the strips in and then I grabbed a clean rag and wiped the spots

I got epoxy on the outside of the hull.

Got a few finger prints at the bow and stern joints.

I am amazed how clean this came off.

I got epoxy on the 2 nylon servo connectors.

I have lots of spares (just got a package of 10) and I can replace

them but I think once the epoxy cures, it may just pop off.

Will see.

More tomorrow. Another strip on the transportation box.

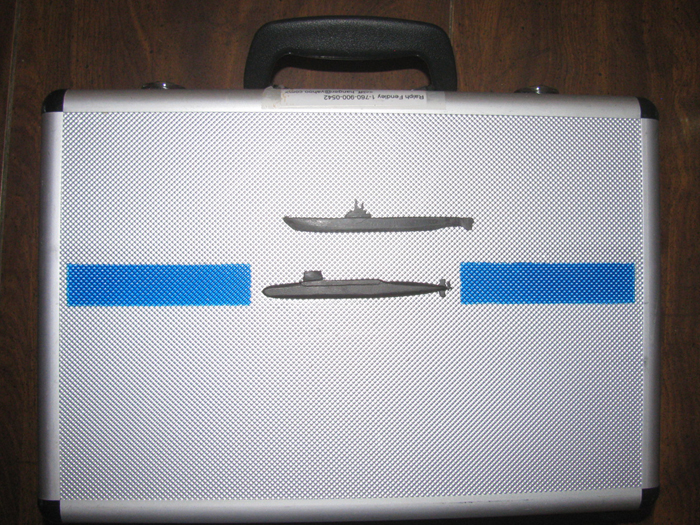

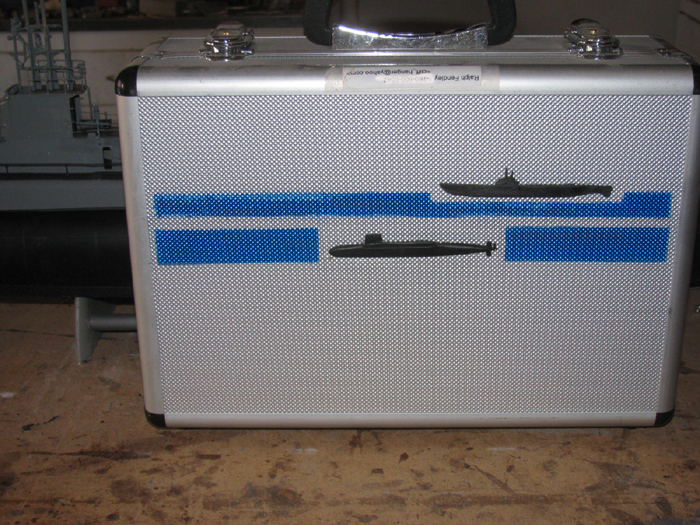

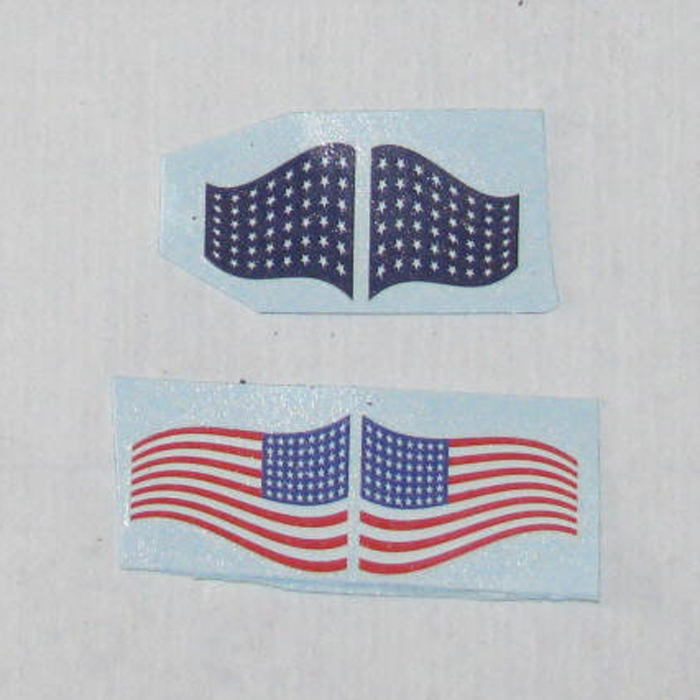

Printed out the needed 3 images of a GATO to make the badge that goes

on the Transmitter case.

Glued them to the plastic pieces with the plastic cement.

They are there so when I get some time in the shop between projects,

I can carve on them to make the 3D.

Put the letters on the transportation box badge.

Clear coated it.

It is now ready to install on the box when I get it done.

The reversed GATO is the template to put the vinyl letters on.

The small images is the size of the image going on the transmitter

case.

(I have cut the 2 pieces from plastic and shaped the back one.

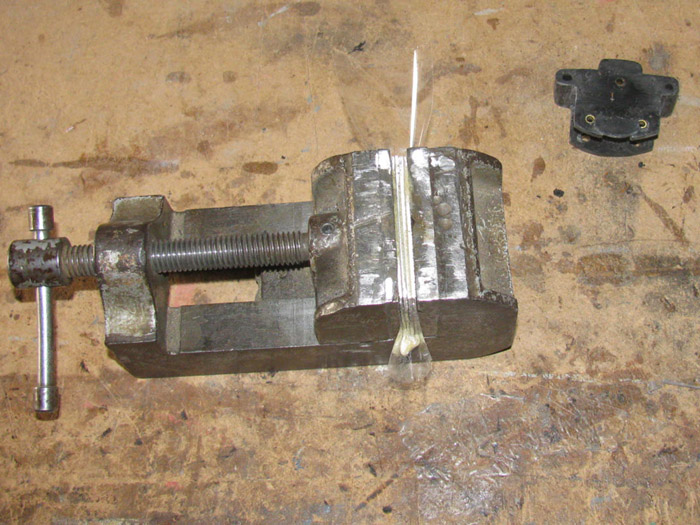

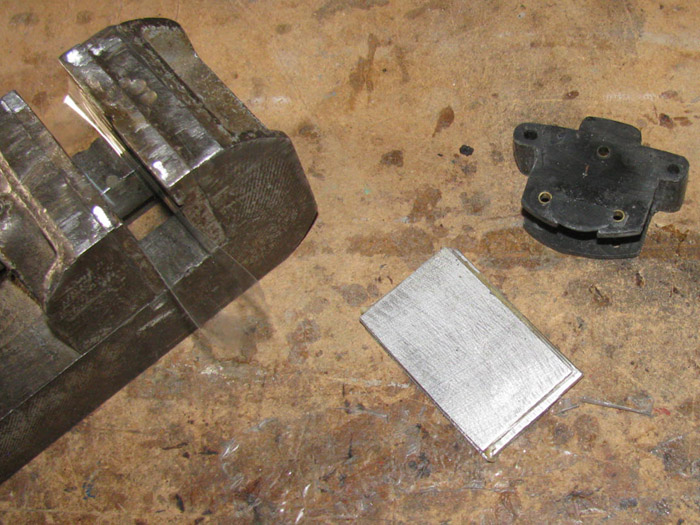

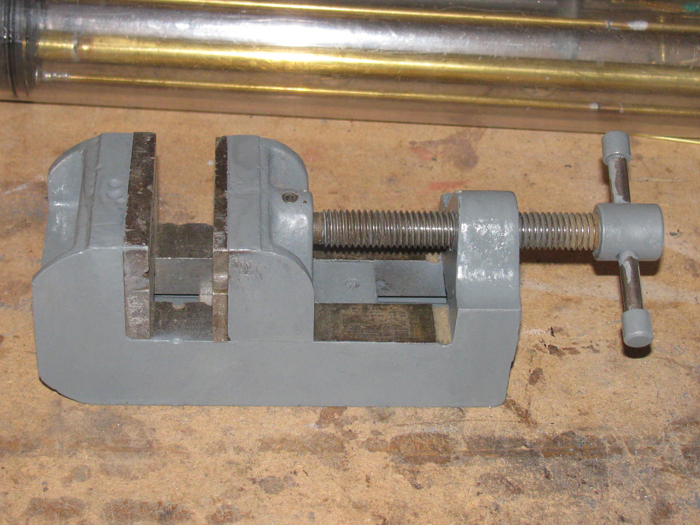

The front one is rough shaped and is on the first in the vise after

applying cement.

The image at the bottom is the transportation box emblem.

December 24th =================================================

Unclasped one panel and started another.

I did this about 20 minutes ago and I can see the glue foaming out

from under the strip.

Went in to the shop and spent 15 minutes shaping the Tx case badge.

I think this will do nicely.

It is just sitting there for now.

I will paint the blue stripe in the next day or 2.

Then I can mount the badge with silicone.

Note" the badges are not to scale.

All badges are 4" long on the cases and 6" long on the transportation

boxes.

December 26th =================================================

The Gato build did not get set aside.

Early this morning I went out and trimmed a box panel.

Move back outside to the metal work bench and glued up another trim

strip.

========================

Came inside and started the ugly job.

Work on kitchen.

Cut the floor out to get to pipes.

Then cut hole to joist for support frame.

Went to town and got parts.

Next I need to lay on the floor and see about cutting out the rest

of the old pipe and installing the new sections of pipe.

1 Tee, 3 straight connectors and about 18" of plastic pipe. 2 pieces

total.

But there is submariner building going on as well.

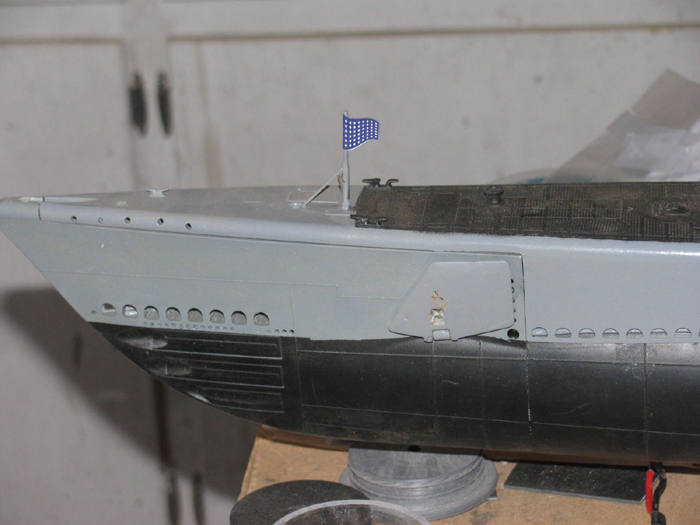

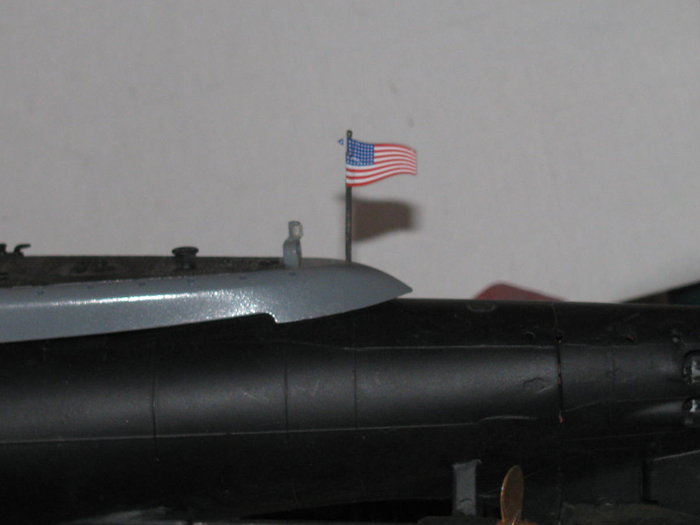

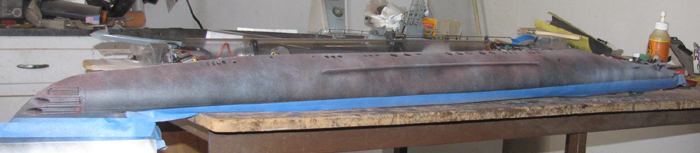

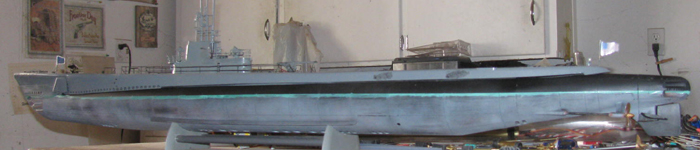

Prepped and painted the bow.

Later I painted the hull.

The stern piece is there somewhere.

It got painted before the hull.

I see I have to clean up the bottom of the bow planes. (gray)

And I will need to paint the top of the bow planes black.

Just a little paint and it looks like I am getting some where.

===============

Back to the pipes.

December 27th =================================================

I have unclasped and trimmed panel 3.

Got panel 4 on the bench and it is glued and clamped.

Looked over hull paint.

Needs a second coat. We all knew that.

--------------

9:45am I have water restored.

Got the hot water tank lit.

Soon a shower and off to a meeting with insurance. (pay the bill mostly)

========

When I get home this afternoon, I may get that second coat on the hull.

Will look over the deck and see if I can do the black on it.

=======

Got home to cold, wind and the annoying dust.

Painting will not happen today.

-----------

Good news is I see no leaks at this time.

Got the lumber and things to start replacing the floor I cut out.

December 28th =================================================

Went outside, not happy about that (38 degrees), and unclasped the box

panel.

Cut the excess glue off.

Went in to the shop to get out of the wind and cleared a place on the

work bench to do another panel.

This one is different in that the trim board needs to hang off the

edge so it will be flush with the side panels when assembled.

This is the top.

Cut all the short trim boards that go across the panels long side to

long side.

I will start gluing those in place tomorrow.

Still in the shop, I lightly sanded the black part of the hull with

really used 180 wet/dry sand paper.

Later today, I may turn on the heater in the shop to get it warm enough

to get the second coat of flat black on.

While sanding I was looking at the deck.

Not sure how I want to paint it yet.

All black upper deck.

Upper deck with that wavy line at the edge.

Just the deck boards leaving the rest gray.

Before I get criticism, remember, I am not interested in being detail

correct.

If I was, my boat would look like all the others out there.

I have gotten myself in to a dangerous position.

I am thinking about trying to do a little weathering. (I hate painting)

Maybe a little wear on the deck walk paths.

If that goes okay, maybe a little rusting.

Maybe, I will just move on to the wtc.

December 29th =================================================

Back from town where I got the nails, screws and hardware to finish

the kitchen floor.

============

It has warmed up a little.

Out to the box panel.

Unclasp and trim the glue off.

Apply glue to the last long wooden trim piece on and clamp.

I also fit some of the cross trim pieces and applied glue.

The steel bars are holding the trim boards down.

Bars are 2.5" square solid bars.

I use to make trailer hitches for pickup trucks.

While I was out working on the transportation box panels, I had turned

on the heater in the shop.

It took maybe 15 minutes to do the wood stuff, it was a little warmer

inside.

I sanded and scribes a few lines on the deck where I had glazes.

Painted the sides of the deck and a few places on top the deck I wanted

gray.

December 30th =================================================

Took the deck outside and placed it on the hull with the conning tower.

(wondering if the gray is too dark?)

Removed the clamps from the panel that was on the bench.

Removed the steel bars as well.

Put the 2 ends trim boards on the the panel.

Setup to do the short trim boards on 3 panels.

Found a few items to use as weight to hold the trim boards down.

Yep, those are small steel targets at about 4 to 7 pounds each.

They will do nicely.

I move each trim board around to get the glue to squeeze all over the

board and get some of the excess out.

If I were to put the weight on without doing this, the boards will

slide off their marks.

I have the bottom panel ready fro trim boards but not enough weights.

December 31st =================================================

Late start this morning.

Spent 30 minutes outside at the metal work bench.

Trimmed the glue from all the short cross boards on 4 panels.

Got the belt sander out and sanded the edges to get the panel and the

trim boards straight and flat.

Got the palm sander out and sanded all the trim board joints to get

the glue flat down to the wood.

Besides being cold (30F) the sky is turning dark and rain clouds are

coming.

I do not want to do any gluing if it rains.

Moved all the panels in under the tool shed roof.

I am going to stop for now but later if it warms up a little, I may

go out to the shop and sand the gray paint on the deck to get it ready

for a second coat.

But that may wait.

I have looked a more photos and I see where I would like to put a few

small holes so the air under the deck and get out.

These will all be foreword in the front 6" of the deck.

January 1st - 2019 =================================================

Assembly of the transportation box.

Sanded the bottom panel to make sure it was flat and straight.

Test fit the 5 panels.

Bottom, 2 sides and 2 ends.

Apply glue, clamps and several heavy boxes.

Clamps on table edge and boxes on back side to hold box panels.

Example:

There are 9 or so boxes holding the panels.

2 are clearly seen inside the box to keep the bend out of the bottom

panel.

Each box weights between 22# and 27#.

December 7th =================================================

The box in the photo above had the glue fail due to freezing over night.

The glue broke apart with very little effort.

Took the box apart and sanded down all the glued edges preparing it

to be reassembled.

Below shows the last panel being regaled in place.

Small boxes inside the box are to hold the open edge level and straight

at the correct distance from the other side.

The small boxes on top are to hold the panel down while curing.

The small 4"x4" boxes weight about 22 pounds.

The 4"x5" boxes weight in at about 26 pounds.

On the ends are small clamps with wooden block to hold the end panel

to it's correct position.

When I place the end panels, I lean them in about 1/8" so I have pressure

on the clamped block when I get to this point in construction.

To finish the box, I will and all the edged then add the remaining 2

trim boards on each end.

Then comes fitting the top panel.

Besides finishing the box, the box will come off the work bench tomorrow

and the boat will go back on the bench.

Went out to the shop to check on the transportation box.

All looks good.

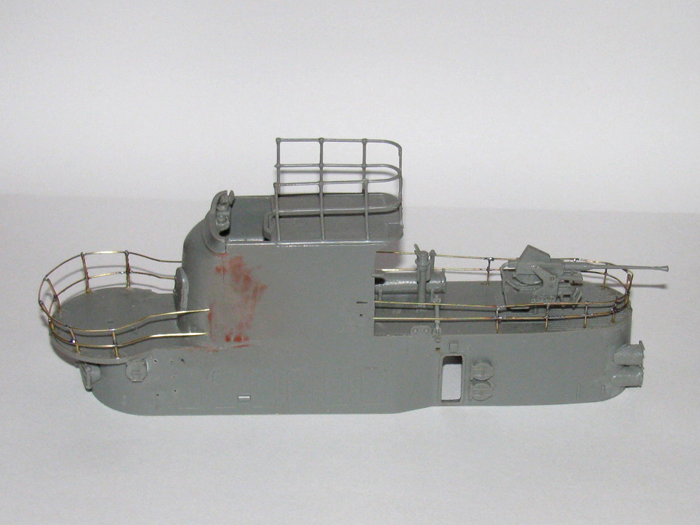

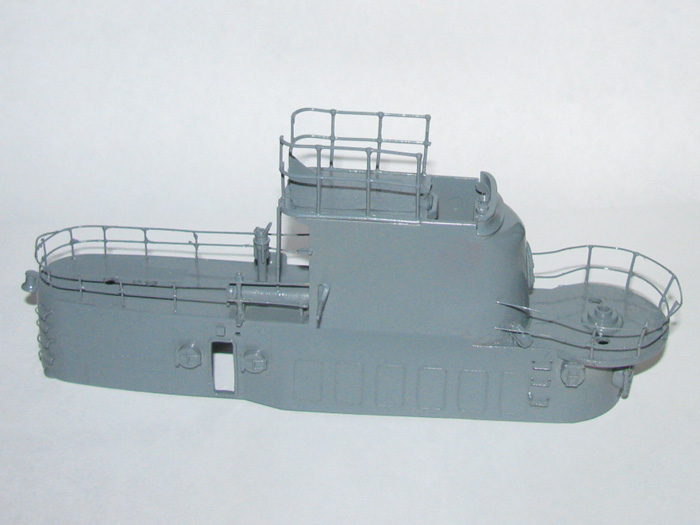

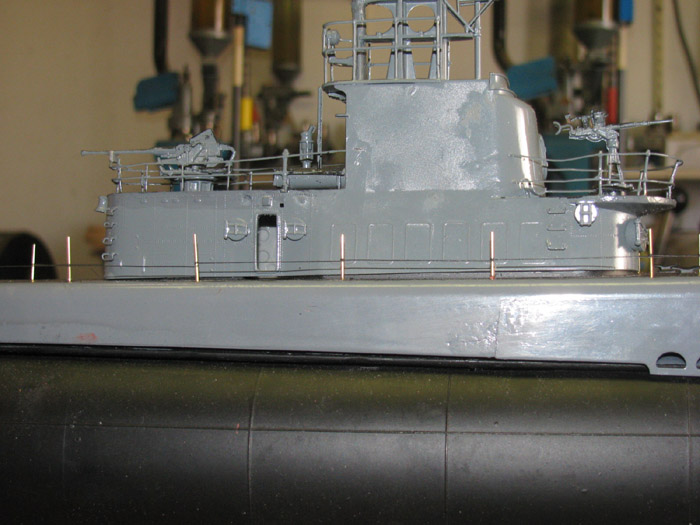

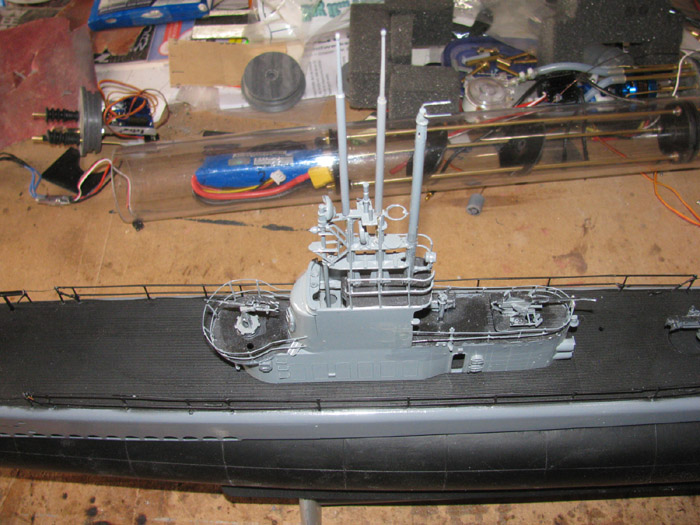

Saw the conning tower sitting on the bench.

Maybe a little time on it making railings.

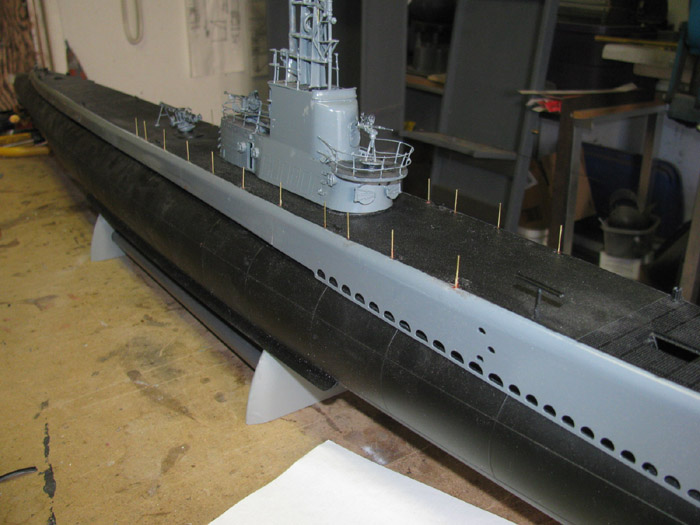

Got the rear and front deck stanchions cut and installed.

The rear railing has been cut to right.

The front railing is still over length.

Before working on the horizontal rails, I will straighten the stanchions

up.

And I need to bend the front deck stanchions to have a slight curve

outward.

The rear deck horizontal railings are sitting in front of the tower

with the needed bend put in.

December 8th =================================================

To main part of the transportation box is all glued together.

The lid has been fitted and all trim boards are currently glued in

place.

Clamped and weighted.

I have cut the boards that go inside the box to support the lid frame.

(Skipjack box build)

I do not have the lumber for the frame.

Going this morning for lumber and hardware.

Hinges and brass bolts, blind nuts and thumb nuts.

Here is the lid for the Skipjack box showing the frame.

Brass bolts to hold the lid on and a hinge for the hull stand. (also

Skipjack)

Took the main box out to the metal work bench because the lid is still

clamped to the shop work bench.

Glazed all the trim joints and panel seams.

Tomorrow, I will belt sand all the trim boards and seams.

Well, that took all of 15 minutes.

Okay, back to the conning tower.

Make 2 balsa boards to hold the upper brass rail in place for soldering.

Make 2 balsa boards to hold the lower brass rail for soldering.

I did the upper rail first and then the lower.

Need to file a few rough solder joints.

CA glue the ends to the tower and the first plastic post.

For the front railing I need to bend all the stanchions.

I will use 2 wooden blocks and make the curve I want to bend the stanchions

to.

Put the brass rod in between the blocks and press together to bend

the rod.

December 9th =================================================

Cleaned up the box lid.

Did some glazing on the trim joints.

Moved on to building conning tower railings.

The brass work is done.

I do need to do some bending adjustments to get the clean look.

Though I have looked at a lot of photos and almost all have beat

up railings.

Only those coming out refit have smooth curve railings.

There are so many different variations to choose from.

The good thing is, I am not a stickler for any particular boat.

I find something I like on a boat and try to use it.

Then I find something on another boat and I will use that as well.

Conning tower railing has been the current project.

The 1/72 kit comes with a 2 rail upper deck arrangement.

The original lay out was for a cable railing and the kit supplied thread

to use for the railing.

The stanchions are so fragile, I decided to use brass.

Looked at photos, a lots to pick from.

add photos here

This one looks like the one in the kit except it has welded pipe rails

instead of cable.

This is the image I used when making my railing.

December 11th =================================================

Cleaned up the inside of the transportation box.

Primed it with gray.

The clamps are holding the bottom outside trim board s that where glued

on after the painting.

Time to build the box stand pieces.

Did the measuring of the box width and the height I want the boat to

sit on the stand.

Cut the pieces.

Cut the notch in the bottom of the stands for the hinges.

Here the stands with the hinges sitting on the lid.

Another look of the stands pieces.

One up and one down.

Moved the transportation box off the bench.

Gluing the half the frame to the under side of the lid.

Also glued 1 stand screw block to the underside of lid.

Third box back is sitting on the screw block. (screw block is where

the screws for the stand hinge will be anchored)

December 12th =================================================

Today's gathering at the pond was canceled due to rain.

I was in the shop for an hour cleaning up yesterday's gluing.

I have 3 more frame boards to put on and the lid will be finished. (the

wood parts)

Cleaned up the glue on the box.

Noticed I missed 4 end trim boards.

I had been wondering why I had these short pieces sitting on the work

bench.

Got them installed and clamped.

Next I will sand the box because there are spots with glaze that need

to be smoothed out.

Then on to painting the outside.

December 13th =================================================

Removed all the clamps from the box and the lid.

Trimmed the glue and sanded.

Glazed the box, again.

Trimmed the glue from the lid.

Sanded the frame boards to round off edges.

Test fit to box.

First coat of primer.

Cut the stand to the shape of the hull.

Notched the stand for the cable that will hold the stand pieces up.

First coat of primer on.

Second coat on all parts in about an hour.

December 15th =================================================

It is suppose to rain today.

This morning it was foggy and wet.

This afternoon, there was a couple of times the clouds parted and the

sun shown through.

Got a second coat of primer on the lid and the stands.

Got 2 coats on the stand saddles where I file the cut to fit the hull

better.

Here is the lid back inside on the bench to dry.

During the second sunshine moment and got a coat of primer on the box.

Still sunshine an hour later and I got the second coat of primer on

the box.

Took the box inside to the bench to dry.

It has started to sprinkle.

Weather says storm coming in is more intense than yesterday.

I got what I wanted done so, let it come.

Tomorrow, I will reinstall the boat badge on the box.

December 16th =================================================

Started by installing the ID badge.

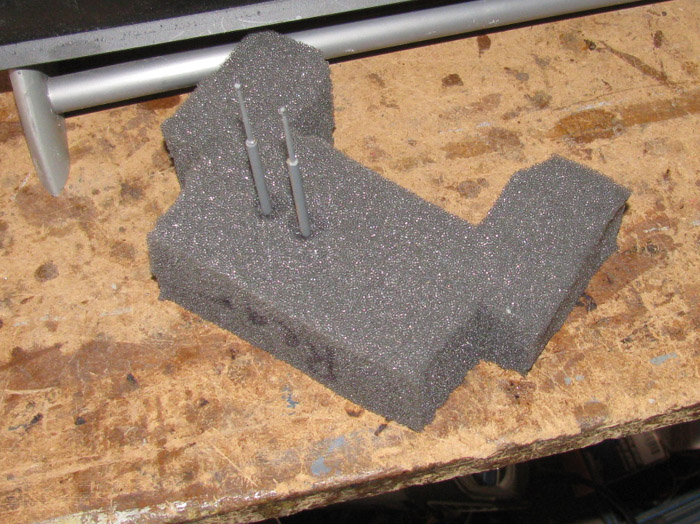

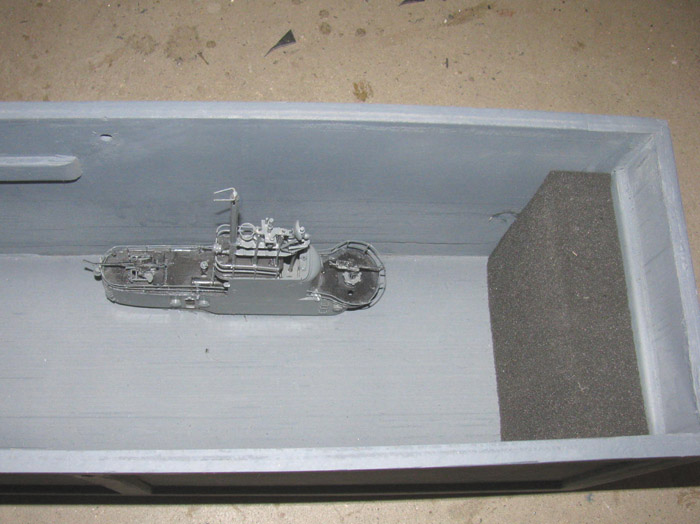

Cut all the foam that is inside the box to support the hull.

Transportation box completed.

The boat is inside.

Hull, conning tower, rear gun and rear upper gun sitting in place.

December 20th =================================================

Late start today.

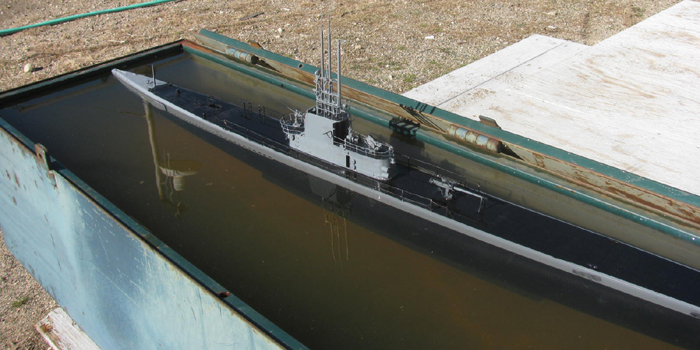

Yesterday was subnormal gathering at the pond.

9 to 12 submarines showed up and a 4 Viking rowers with sails.

My Akula II ran great.

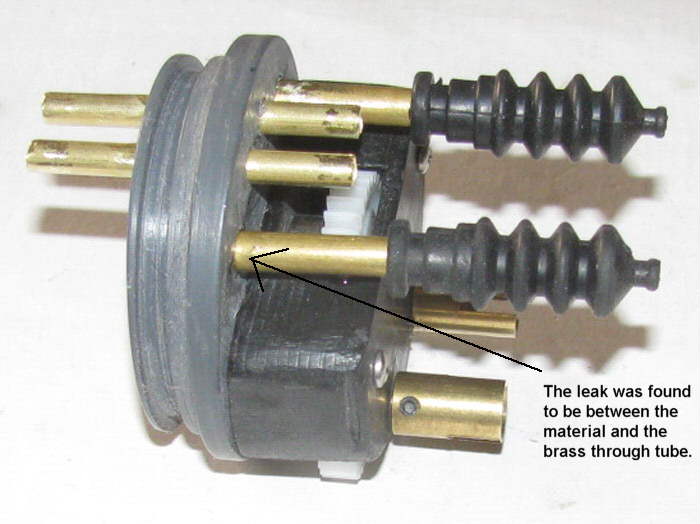

My Skipjack ran great but there is a small air leak.

Only get bubbles when fully submerged and the pressure in the cylinder

is at it's highest.

No water in the cylinder after 2 one hour runs.

I am happy.

Now I need to find where the bubbles are coming from and see if I can

stop them.

-----------------------

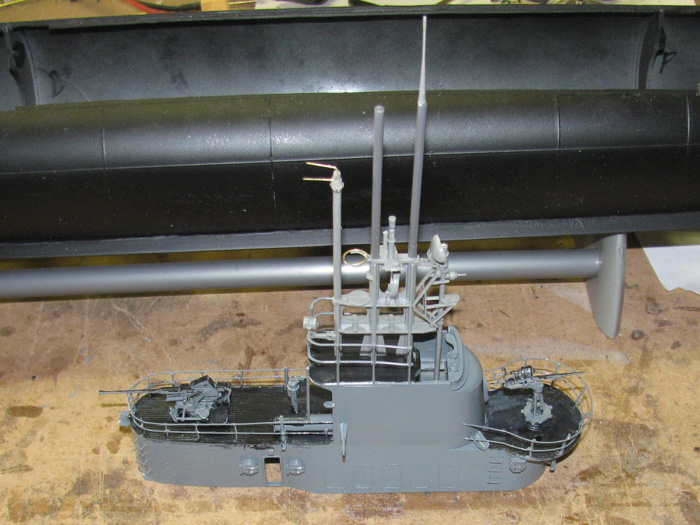

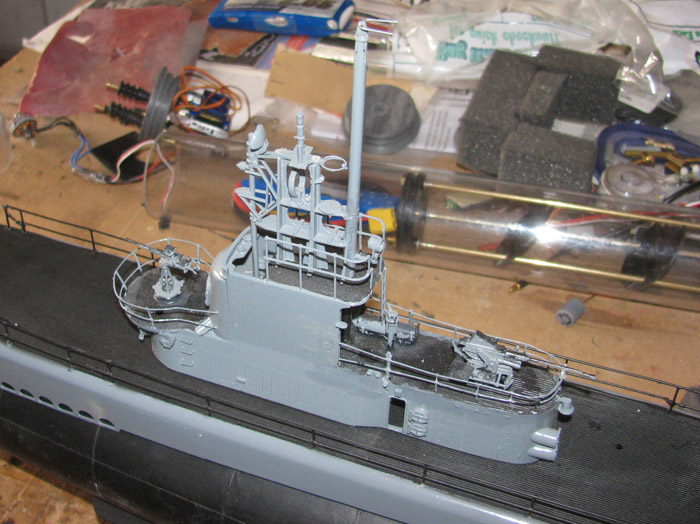

In the shop and back at detailing the conning tower.

Got the tiny wire steps installed.

Lost several.

Found all but 2. (made them out of .020" brass wire.

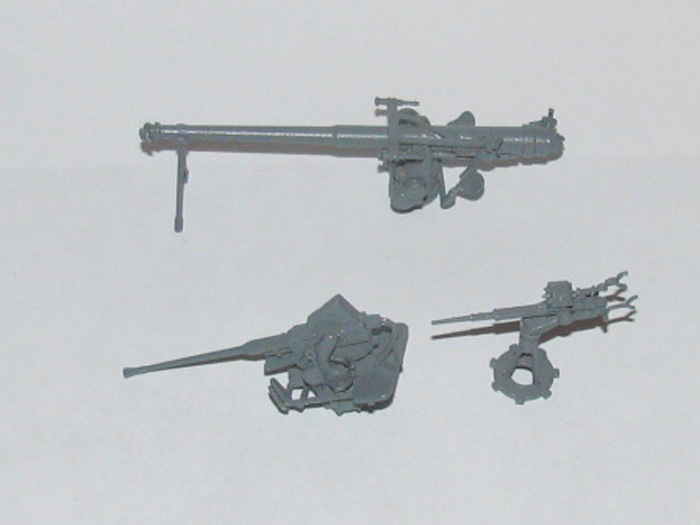

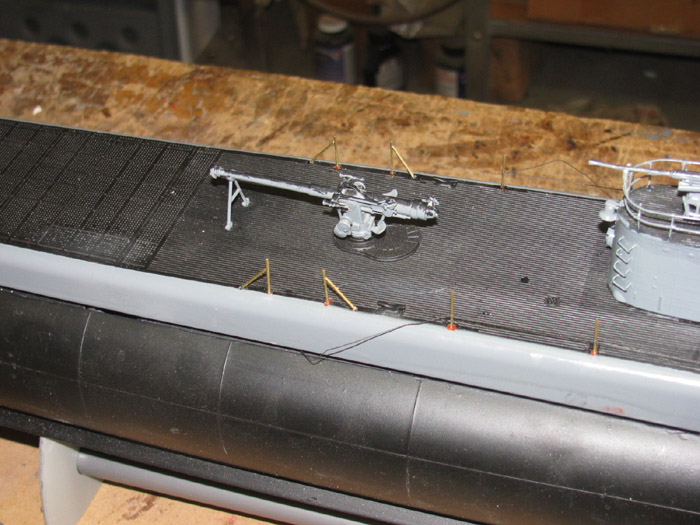

Built the third deck gun.

The little one.

Drilled a couple of holes to let air out from under the conning tower

deck.

These holes are under the guns.

You can see them but you have to look for them.

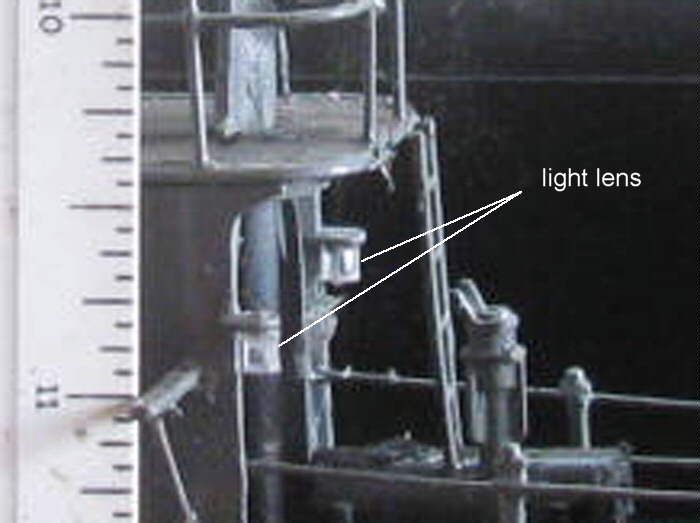

Detailed most of the periscope tower.

Not sure I got everything on there.

There are some parts I decided not to even bother with.

Put a couple of pieces I think are metal support frames on the tower.

I see I have to make 2 bars for the front of the tower railing.

The plastic ones did not survive removal from the tree.

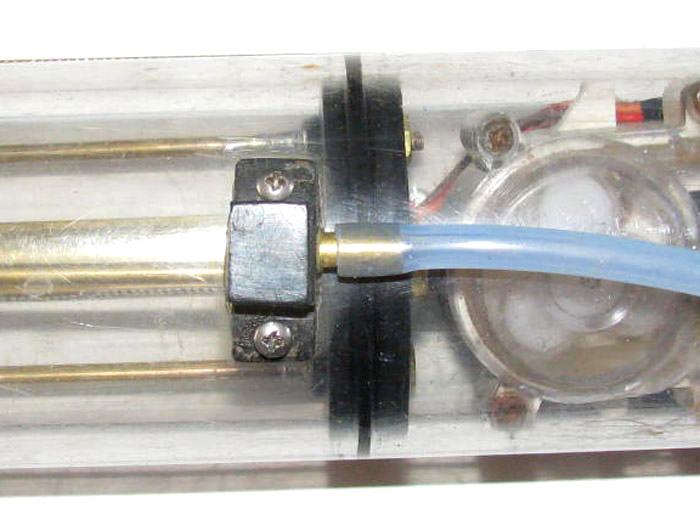

I have got to find my small air and water pumps.

I will get a photo or two tomorrow.

Lots of parts assembled but not put in places to let the cement cure.

December 22nd =================================================

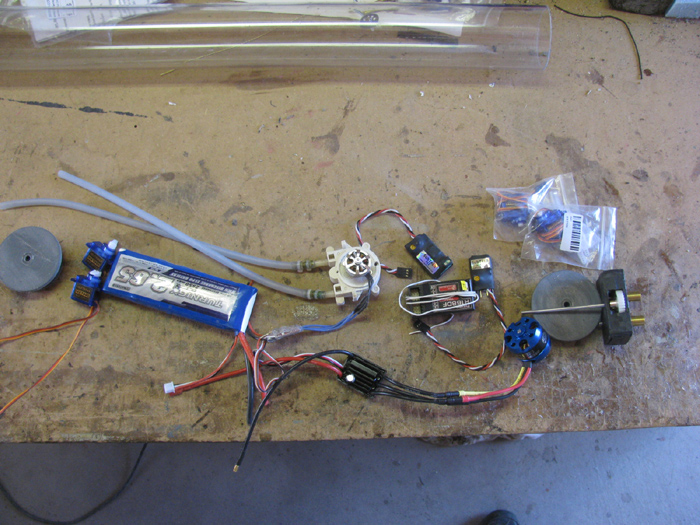

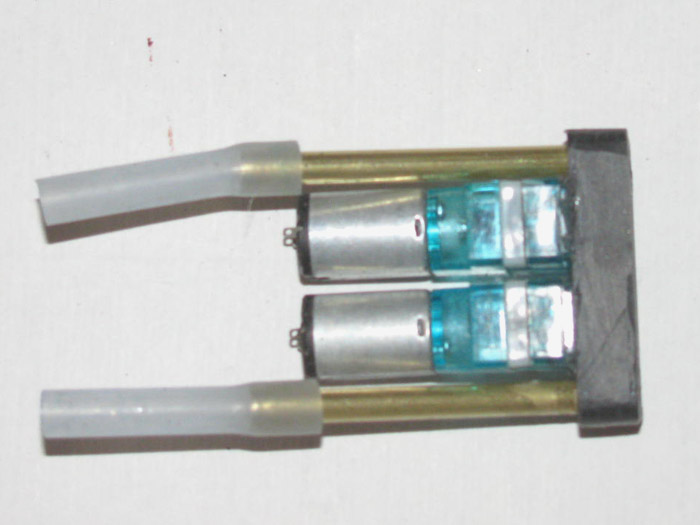

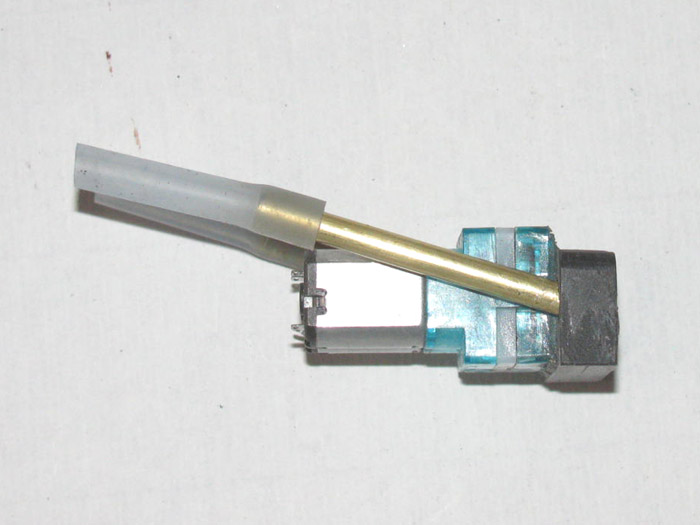

Today's project was to find the small pumps I have.

Looked every where.

I found the centrifugal water pumps.

Not really what I wanted.

Looked in the parts boxes in the shop.

Still can not find the air pumps.

Still looking.

I did look at the pump that was removed from the Skipjack.

Hump

With a little filing, on 2 opposing screw tabs, the pump fits in the

smaller cylinder of the Gato.

I originally was thinking of putting this in the George Washington.

But if I can not find the air pumps, this will do.

(For the GW, I happen to have another one of these pumps and replacement

motors)

Got to go in to town today.

So there's not much I can do this morning.

I did get a tack coat of gray on the tower minus the periscope stuff.

If you look closely, you can see the red glaze showing through in spots.

Will get another coat on later today.

Later in the day.

Conning tower is painted.

Tack coat and 2 full coats.

While I was painting gray, I painted the 3 deck guns.

January 23rd =================================================

Painting the conning tower decks flat black.

The gray is showing through.

But I am not sure I don't like it.

I may leave as it is.

Put a little thin paint on the top surfaces of the guns.

There is a little touch up to the sides of the tower where I got wild

with the brush.

Here the deck is taped off ready for painting flat black.

Currently in the house where it is warm to dry.

I'll get another photo in an hour or two after I pull the tape.

Time has past.

Painted

Tape and paper removed.

Deck sitting on the hull.

Need to make a tube for the air pump intake.

I used a 5/32" brass tube so I can have 1/8" ID for the air pump.

I should have done this before assembling the masts pieces.

I could have used the center mast.

As it is, I used the rear most mast.

I cut the mast out of the assembly with a Dremel saw blade and exacto

knife.

Removed the search light to use on the new mast and I removed the head

of the mast to use on the new mast.

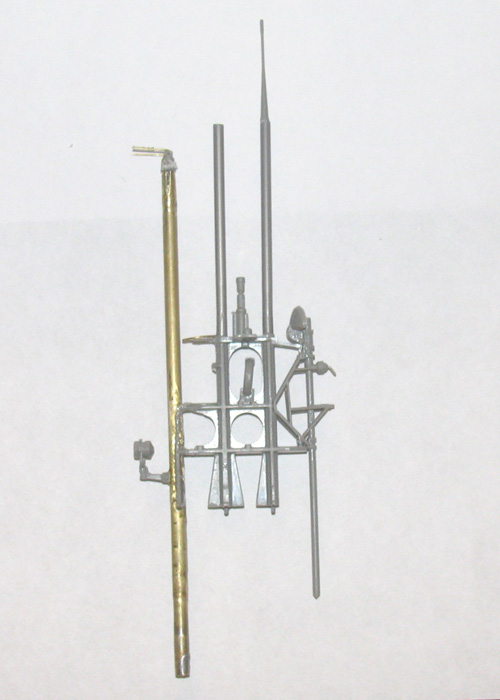

This is what I ended up with.

The mast is a little bigger that the others but it gives me the needed

1/8" ID.

I drilled down through the deck of the tower to make a hole big enough

for the new mast.

Then I turned the tower over and drill through the bottom of the tower.

Did a little knife cutting to get the stanchion out of the tower.

Set the assembly on the conning tower for a look.

There is about 3/4" of brass tubing under the deck to attach a rubber

hose to.

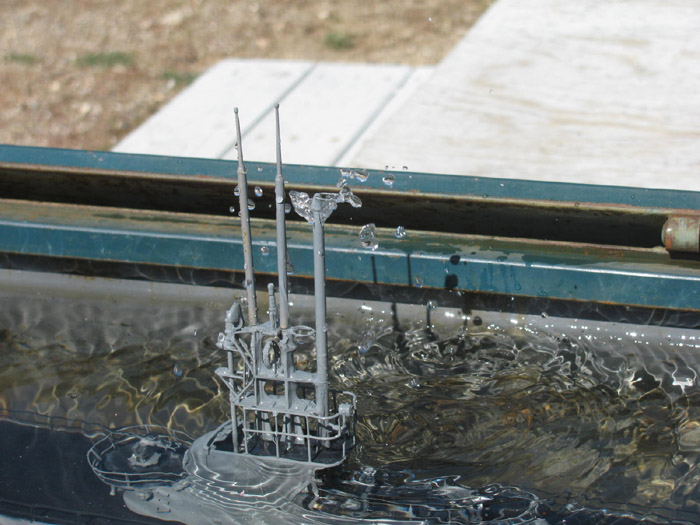

January 25th =================================================

I have worked on the Skipjack air leak and it is ready to go tomorrow.

========

Did a little on the Gato.

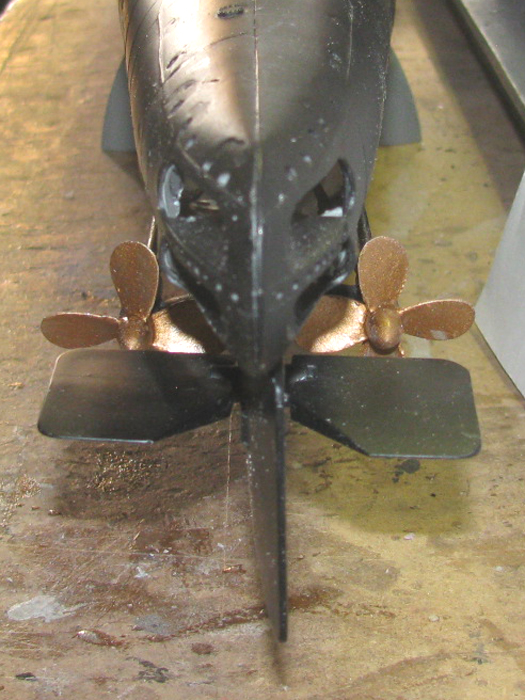

I polished two lengths of stainless 1/8" rod for the propeller shafts.

Slipped them in to the shaft support bearings for a look and I slipped

the propellers on the shafts for a look.

February 2nd =================================================

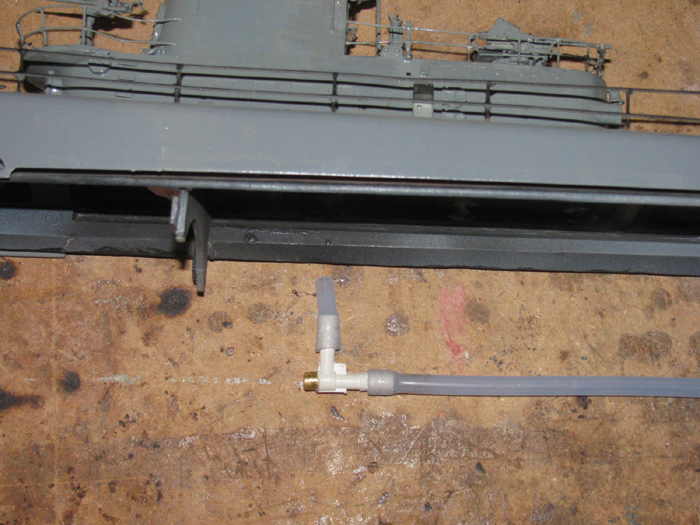

I got a small stainless bolt to hold the rear deck to the hull.

There is a frame under the deck at the rear tow eye.

This is where I am going to put the bolt. (bolt in threaded hole)

The plastic frame is thick enough, I did not use the nut.

I threaded the plastic.

Deck set on the hull and the hold down bolt in place.

I will touch up the paint later.

There are other placed to do.

The foam in the hull can be seen in this photo.

There is room for more if needed.

That will come near the end of the build.

February 3rd =================================================

Fit the rudder so it will travel full right and full left. (touch the

planes)

Had to remove some of the torpedo door plastic. (I would leave the

torpedo doors off if I do it again.. Interferes with the control horn)

Fit the plastic piece that holds the dive planes in place.

Just a little filing to get the rudder to clear the small bolt head

that holds the plastic piece on.

Made another periscope top out of brass.

The front one this time.

Touched up all the paint.

Where I filed material off and some small scratched caused by fitting

the deck to the hull.

5 minutes at most.

Will clear coat it when it warms up.

I may try some very light weathering or more like deck path wear.

With all this fresh paint, it does look strange even for a boat coming

out of overhaul.

There should be deck wear from yard worked moving about the boat in

the yards.

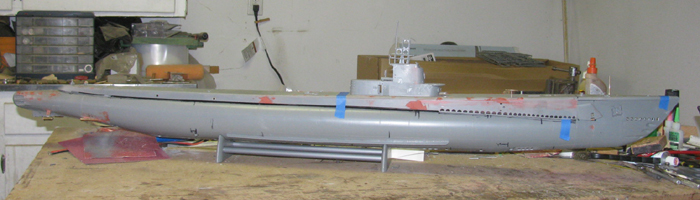

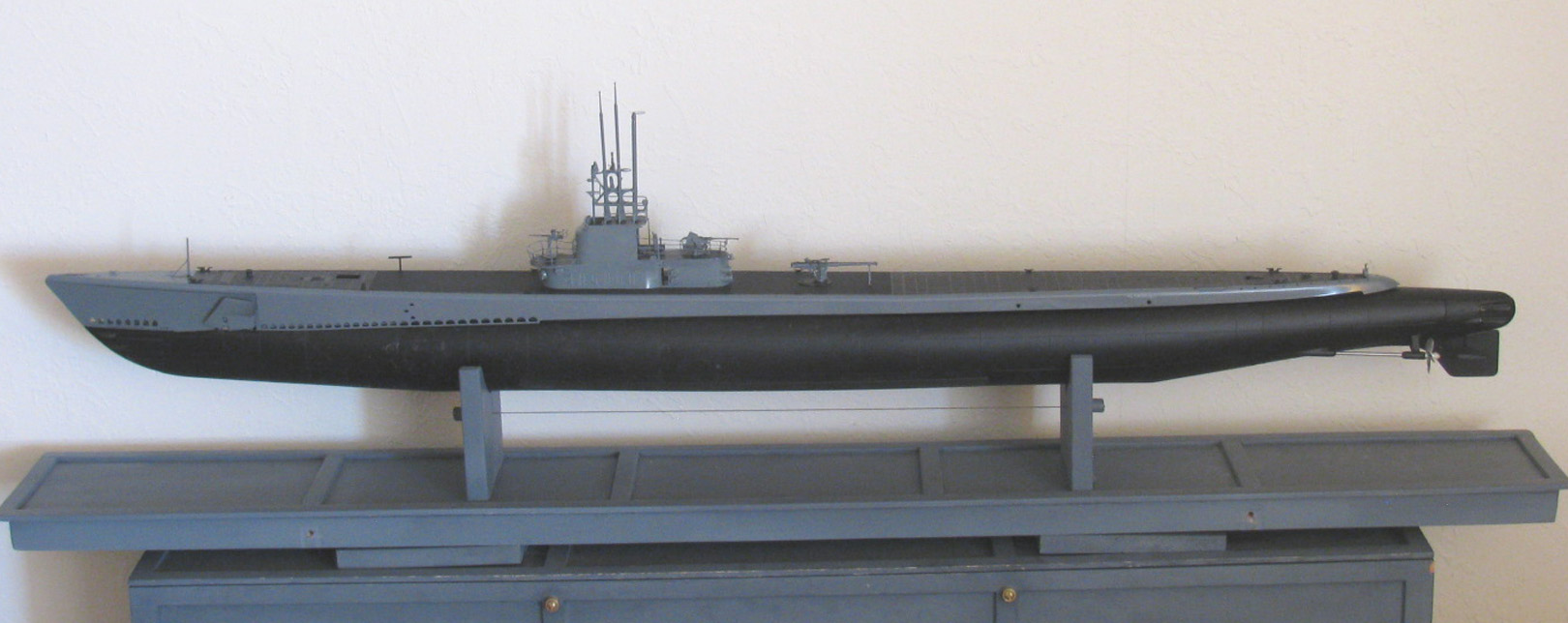

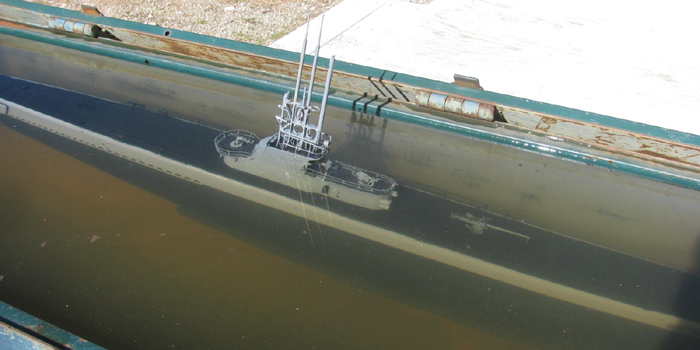

Here is the boat sitting on it's stand

February 4th =================================================

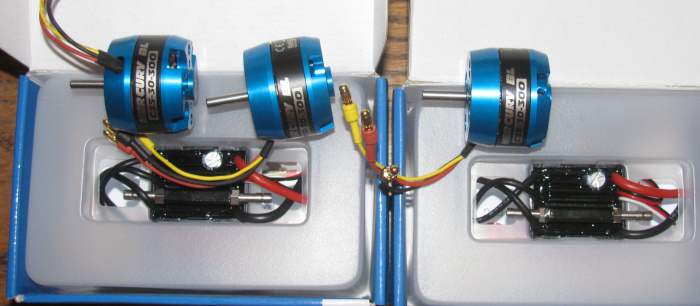

Was opening up the Skipjack to find the problem(s).

After isolating the ballast tank motor, I found it no longer works.

New motor and controller ordered.

The controller may not be bad but if it is, I have one coming.. Could

end up being a spare)

February 5th =================================================

Today will be a very short day in the shop.

I am not going to try working at 38 F for a high.

But I will get my 10 minutes plus on the Gato.

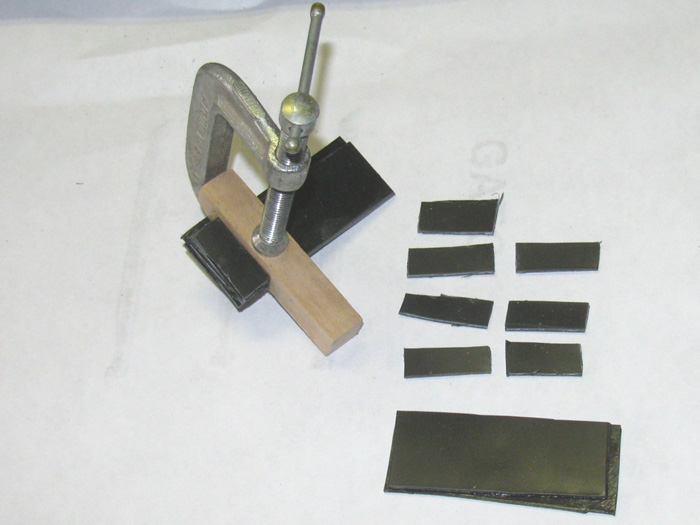

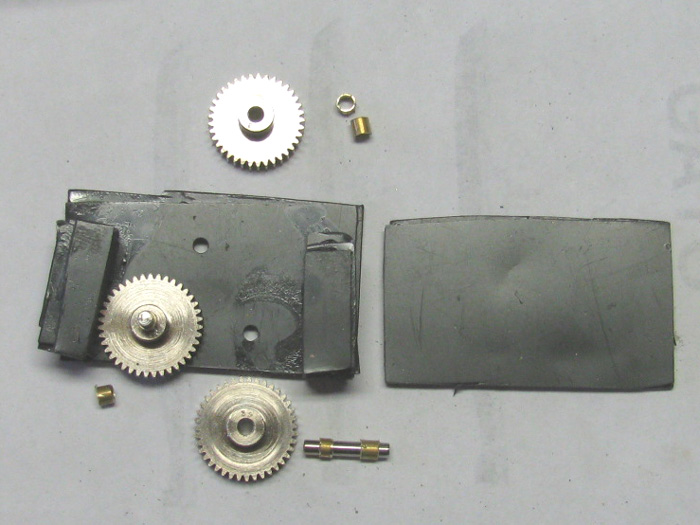

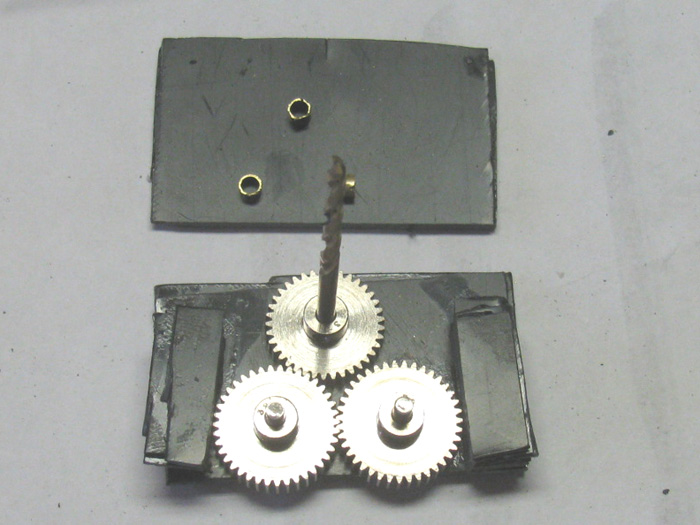

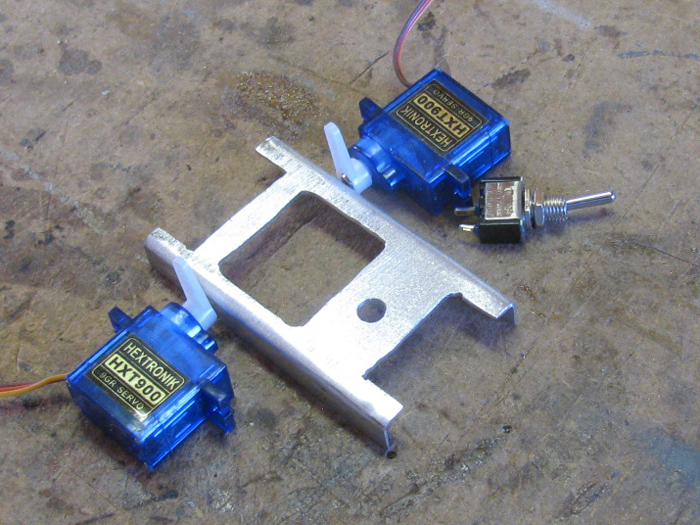

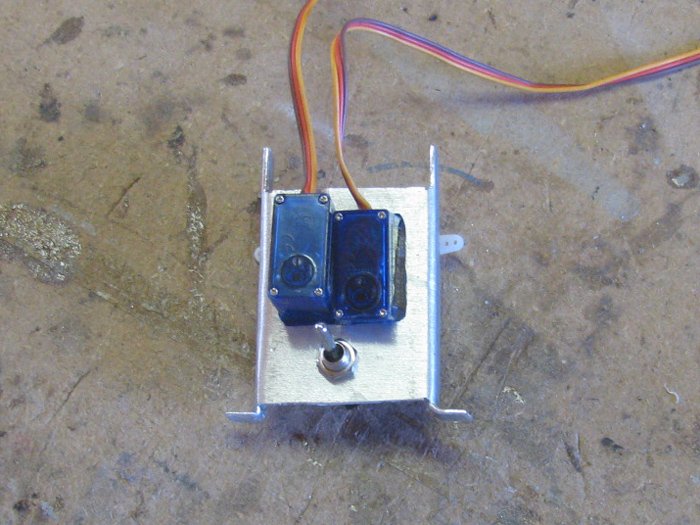

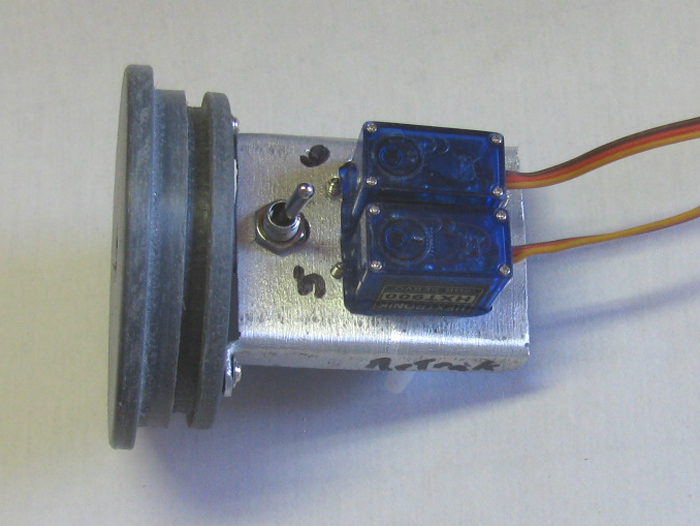

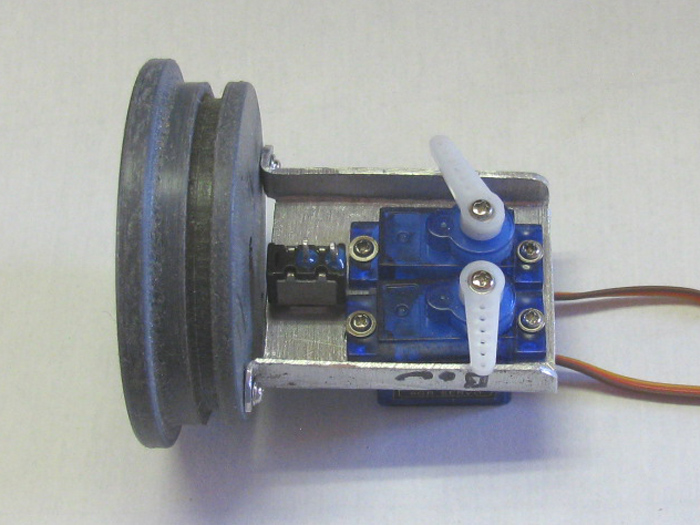

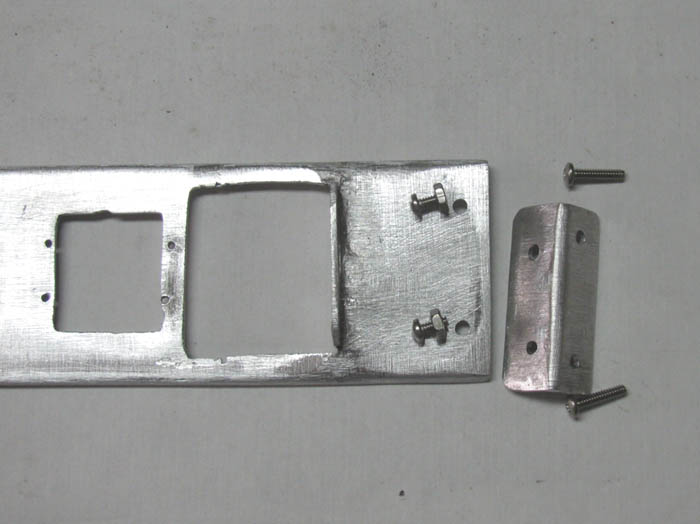

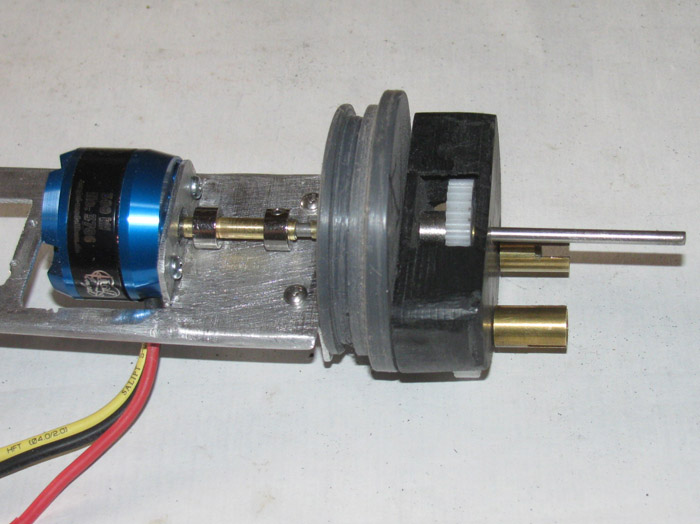

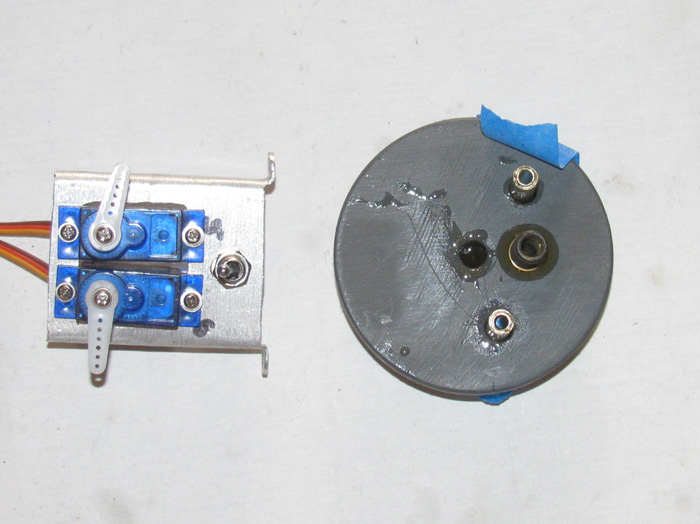

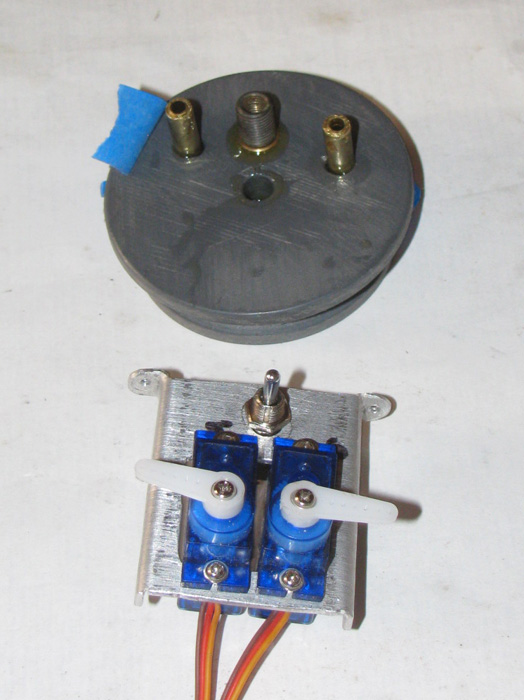

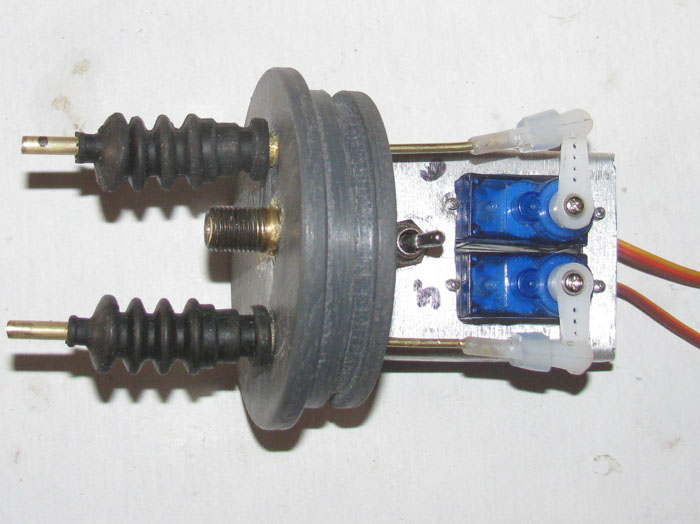

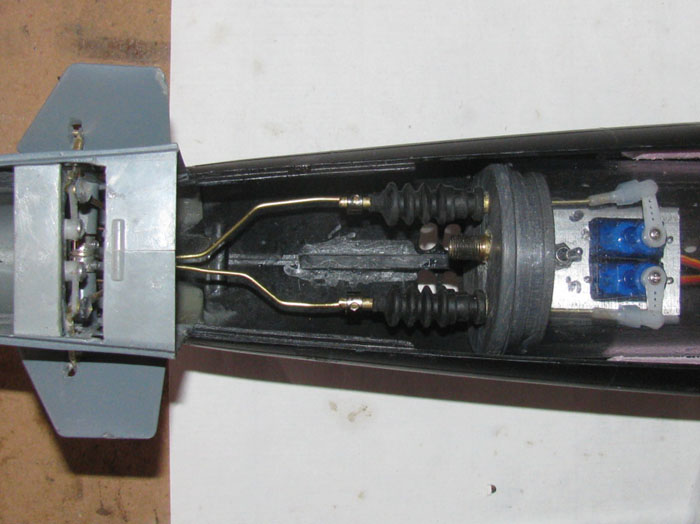

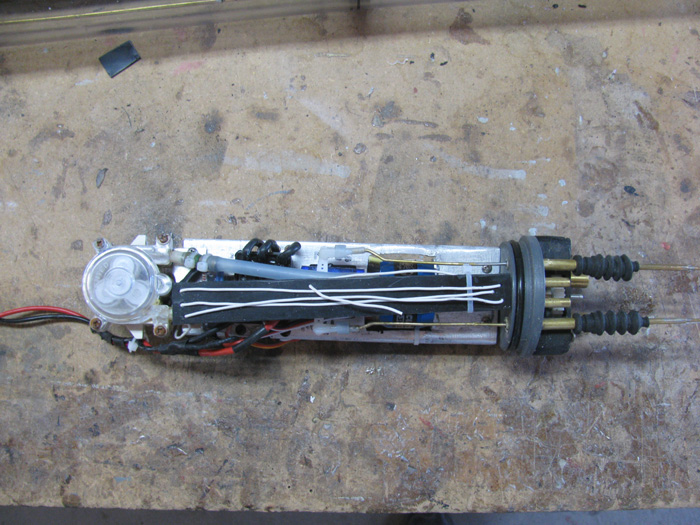

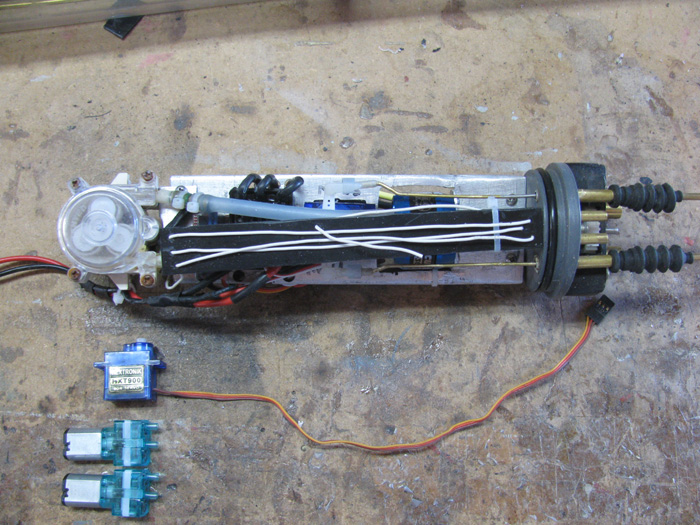

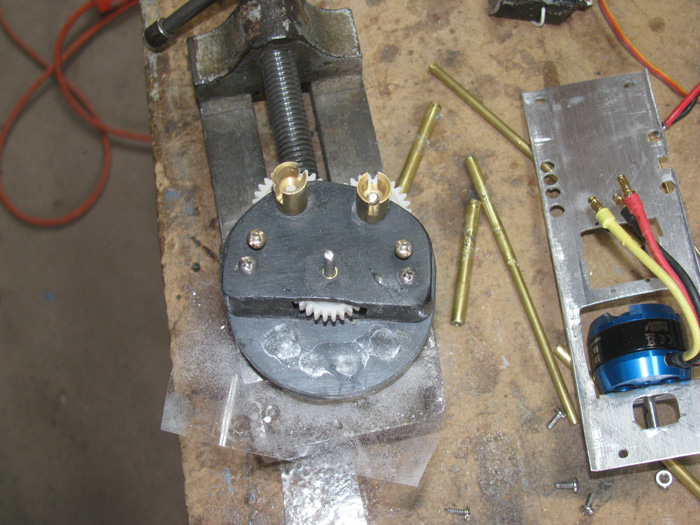

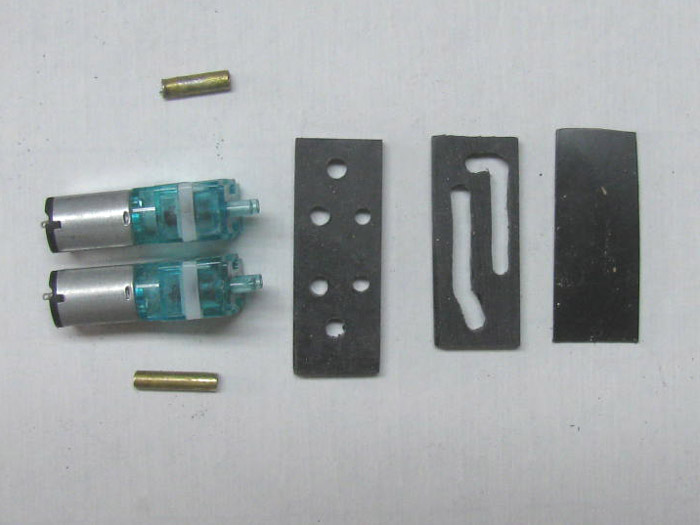

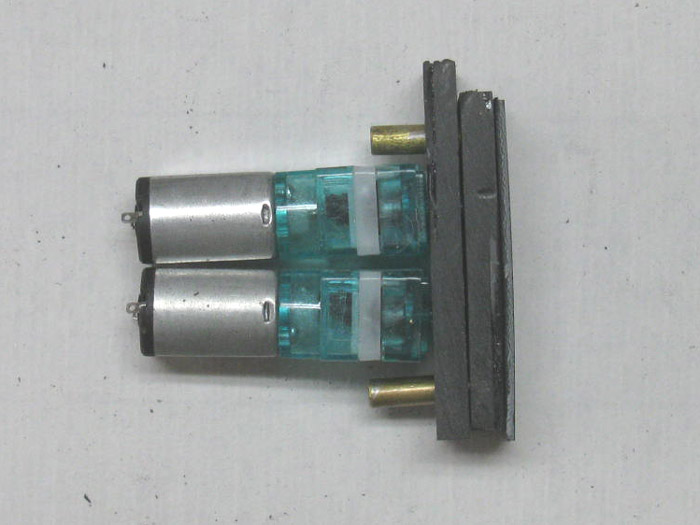

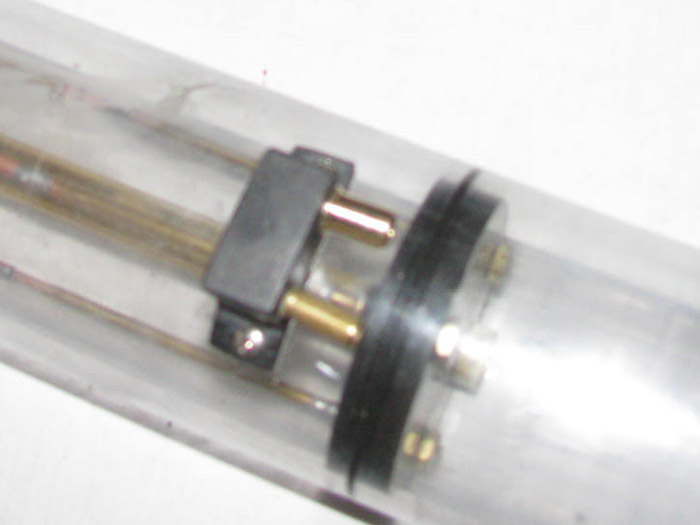

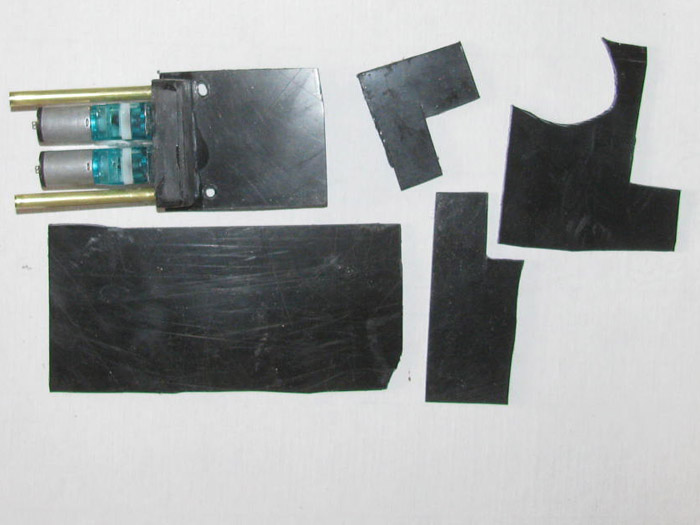

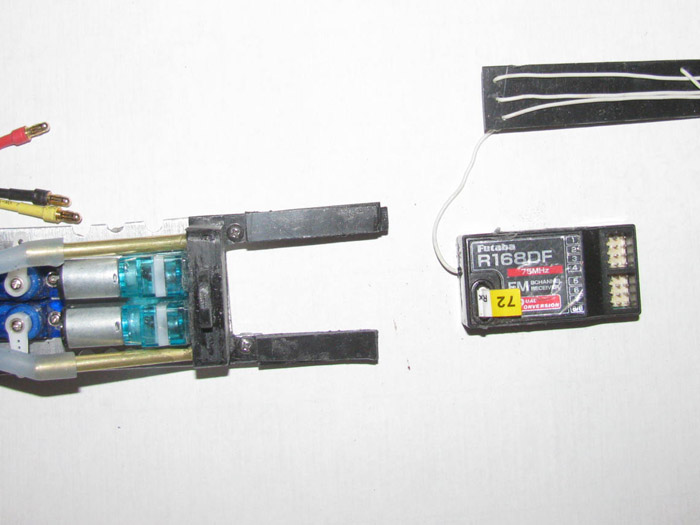

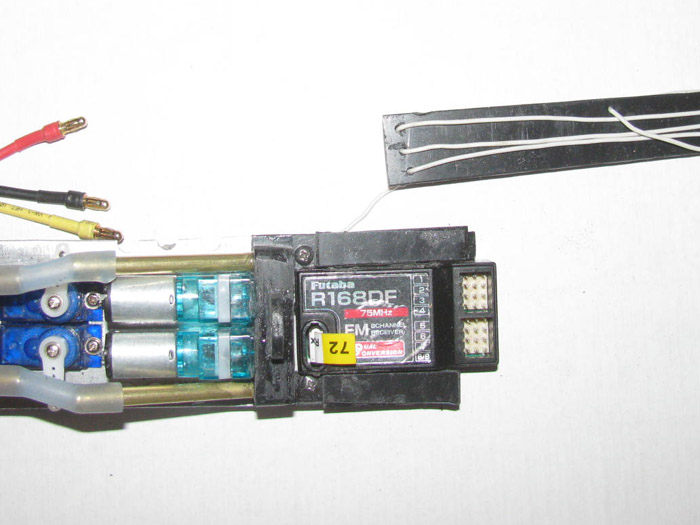

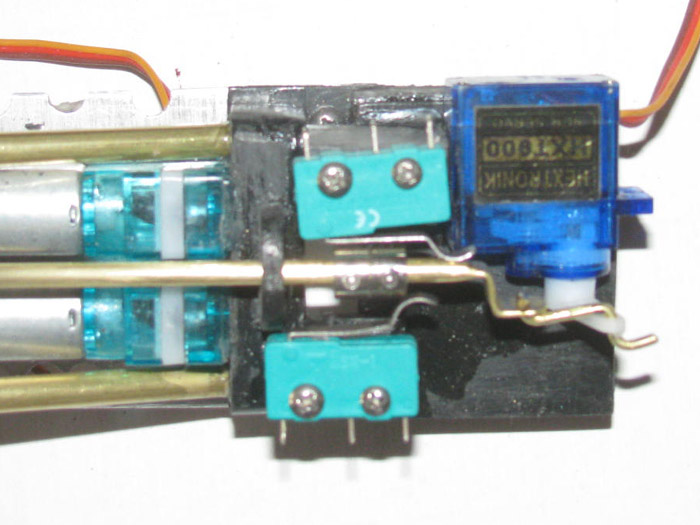

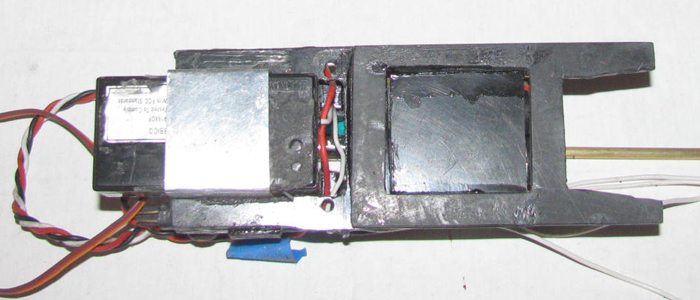

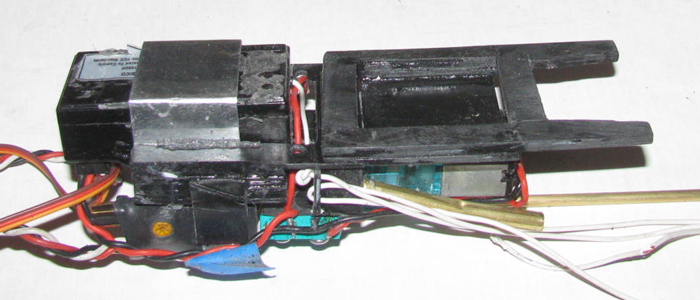

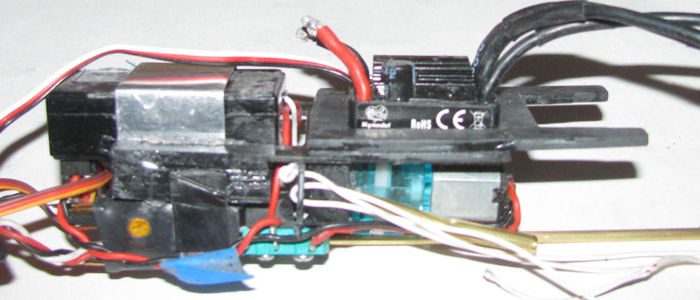

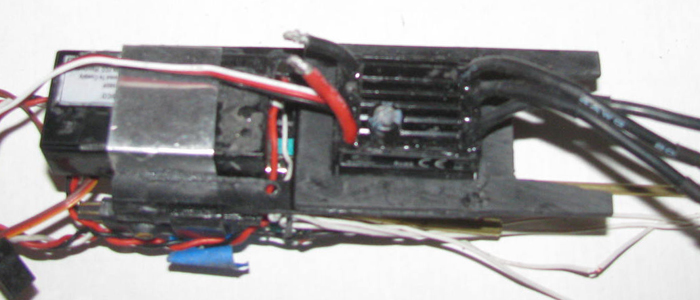

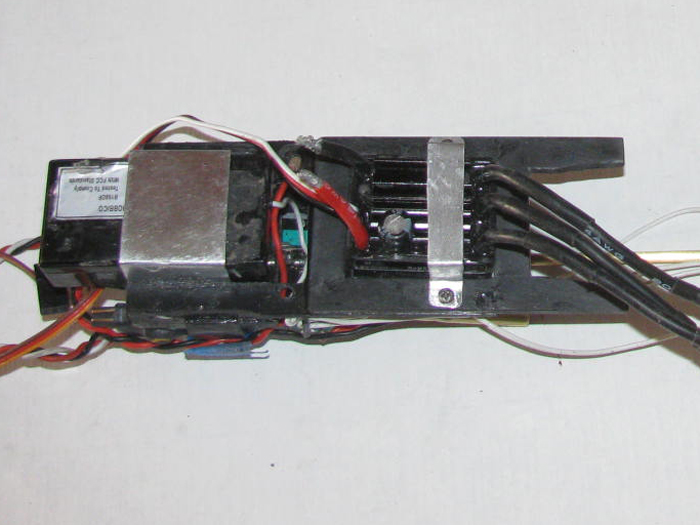

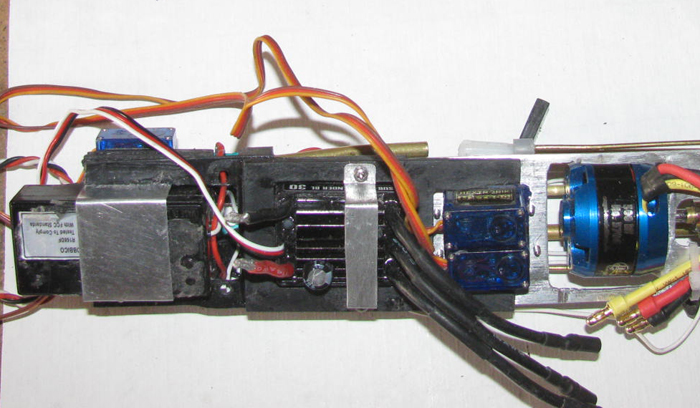

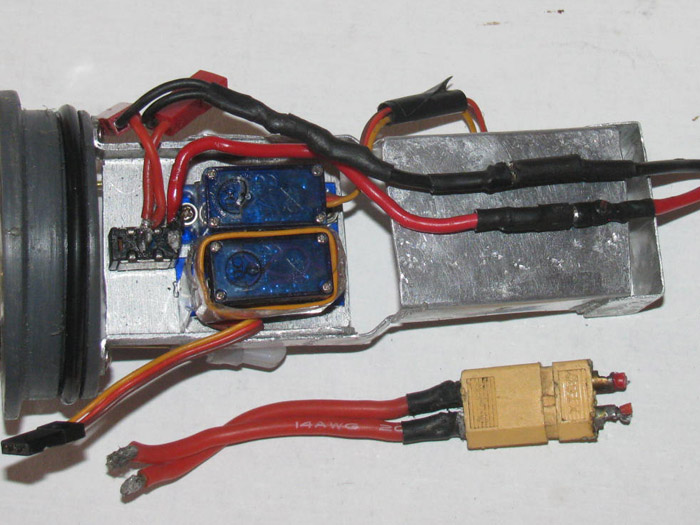

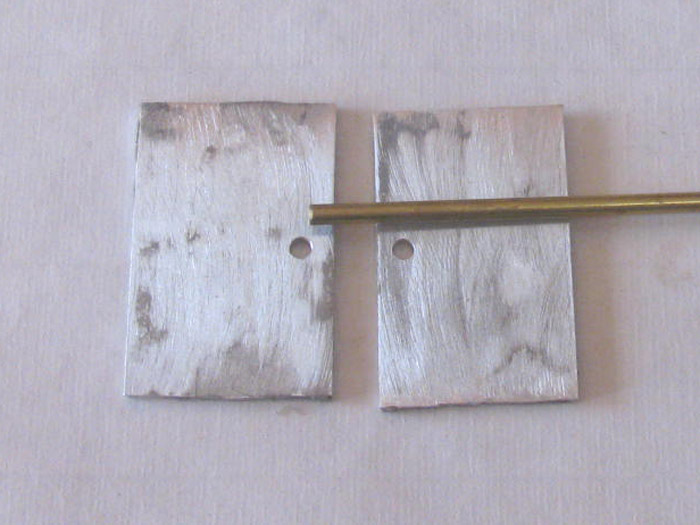

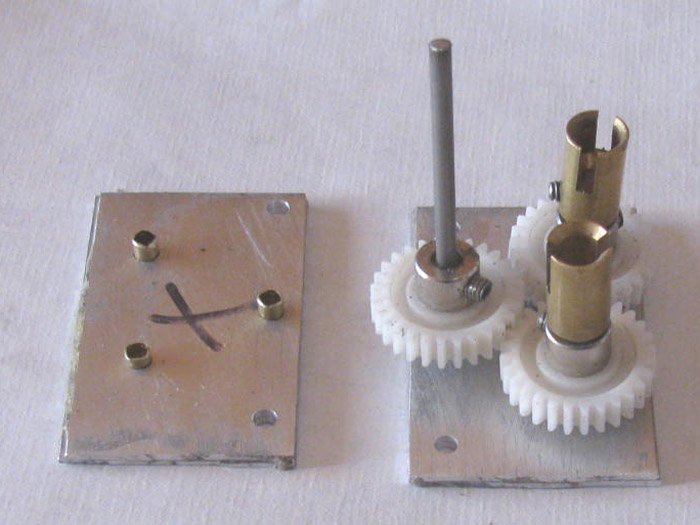

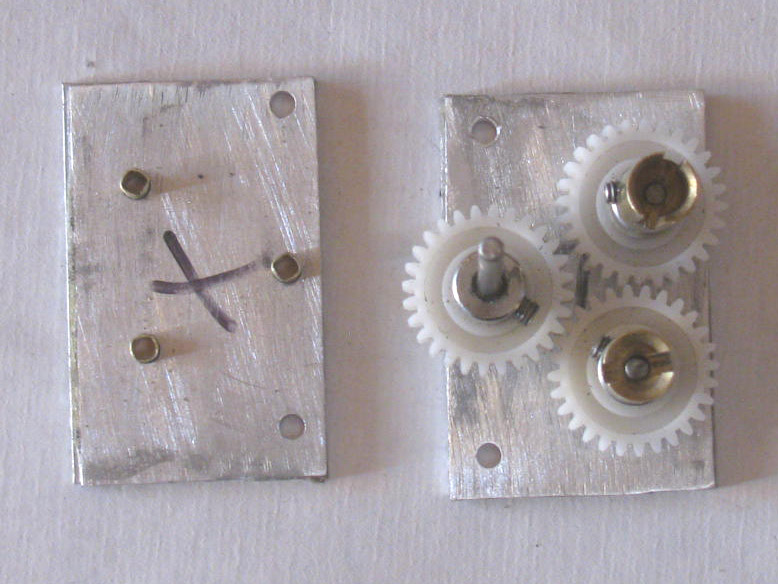

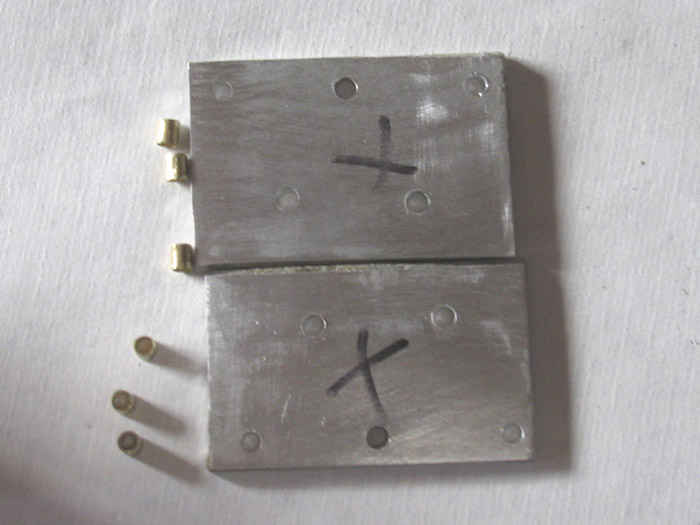

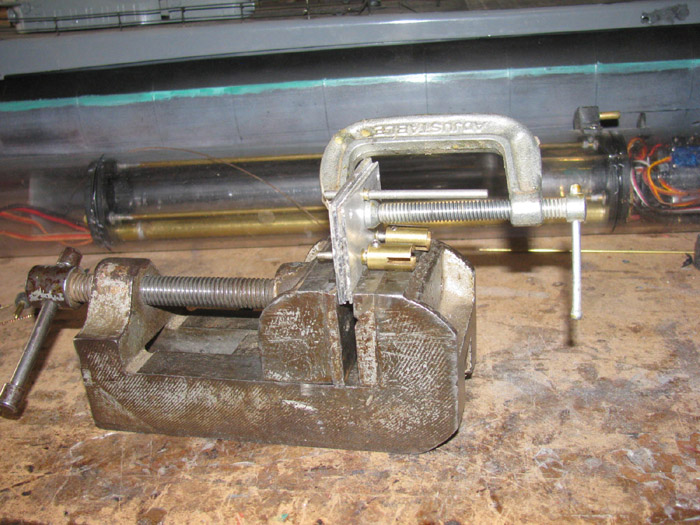

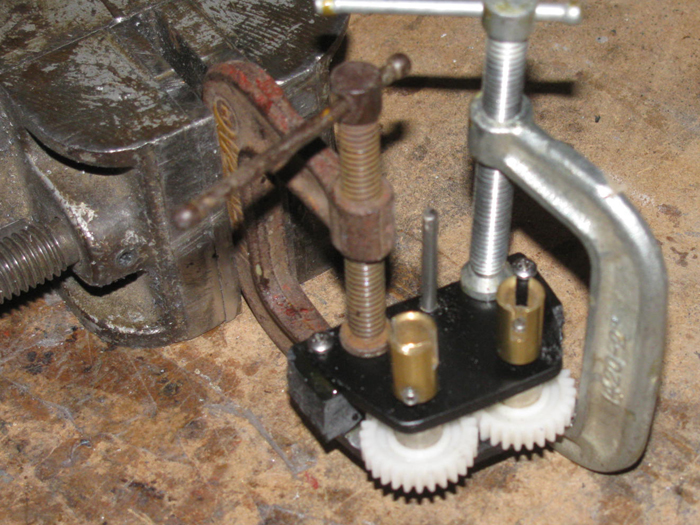

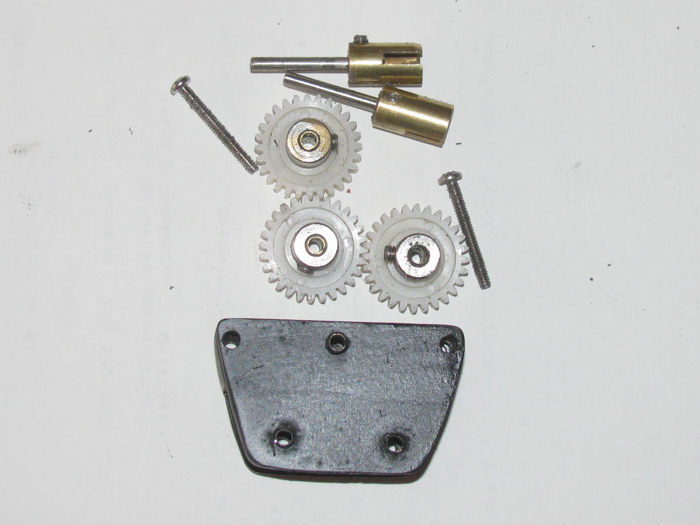

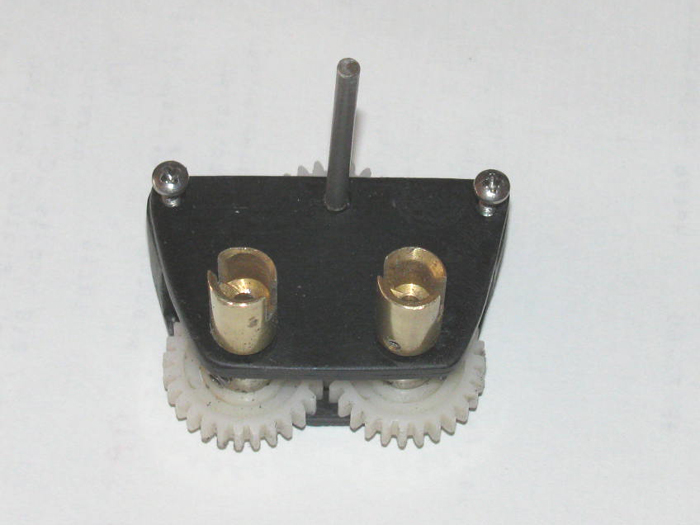

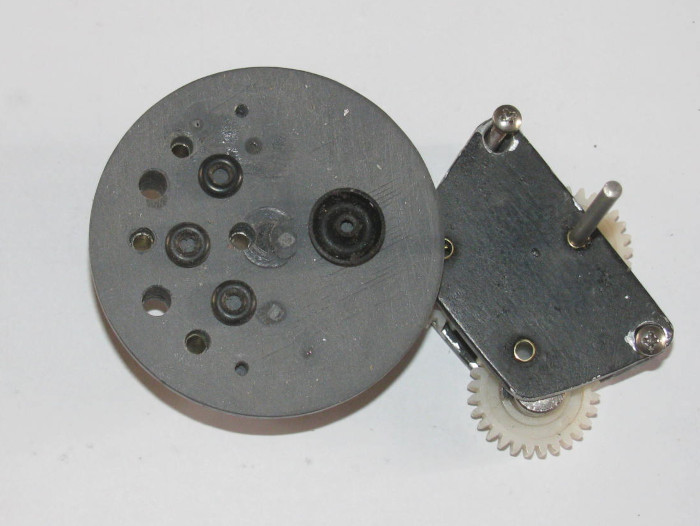

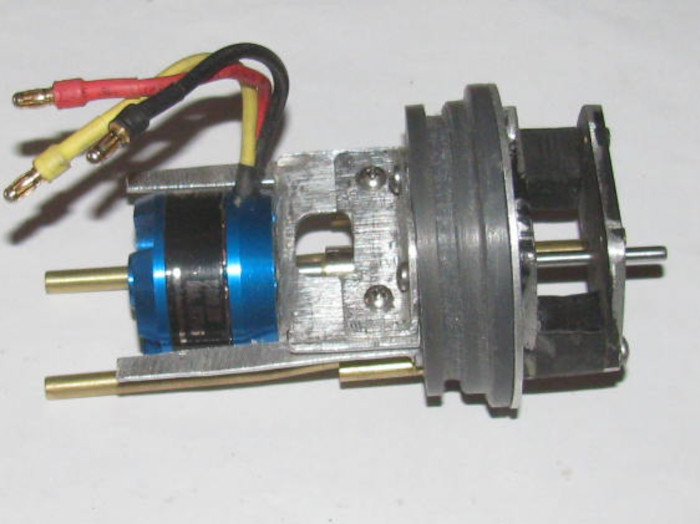

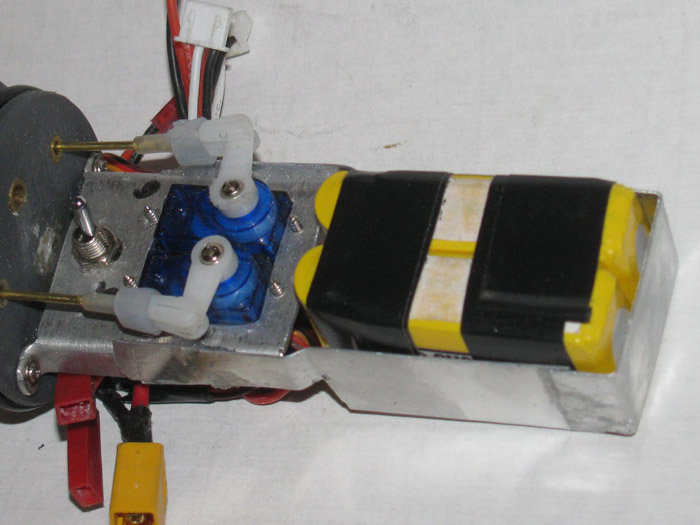

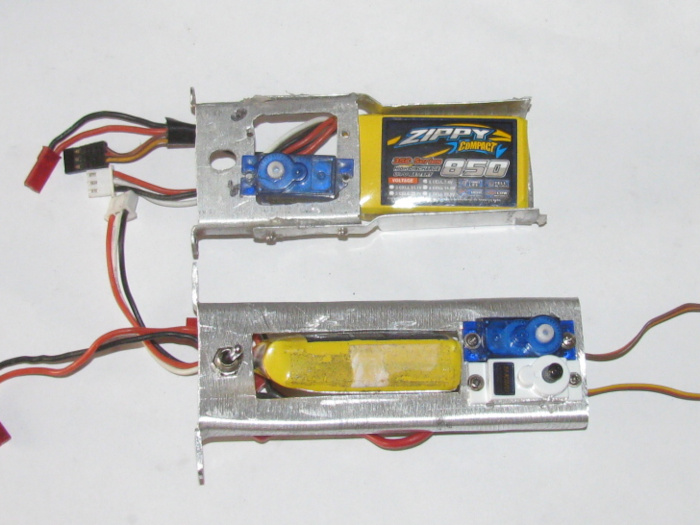

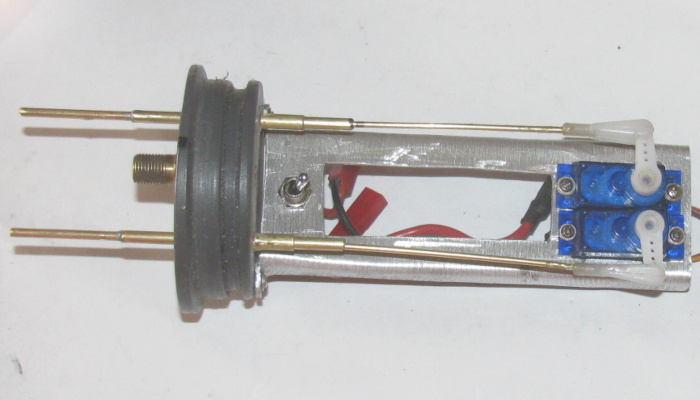

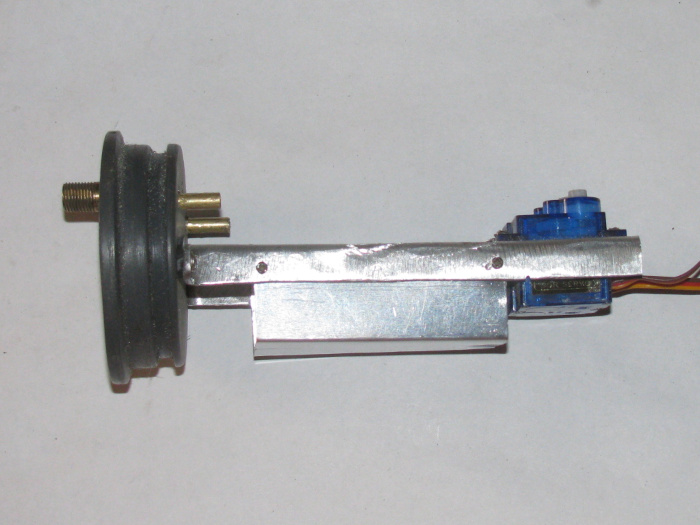

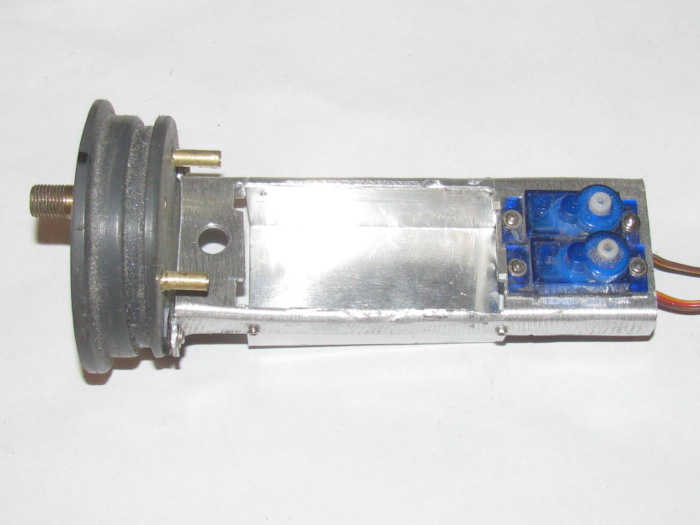

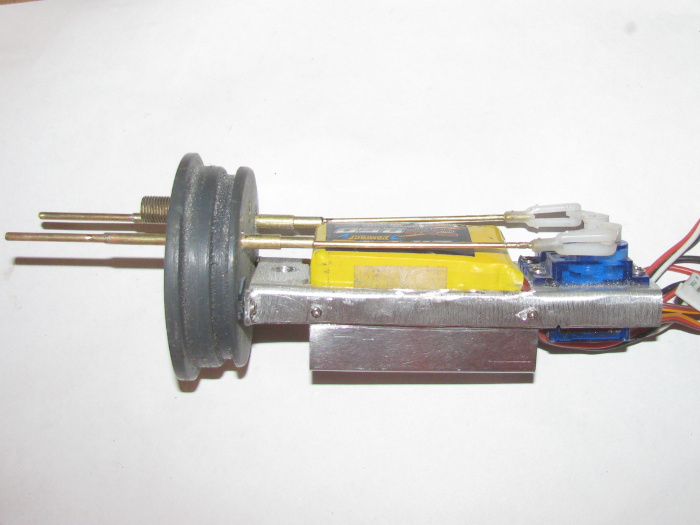

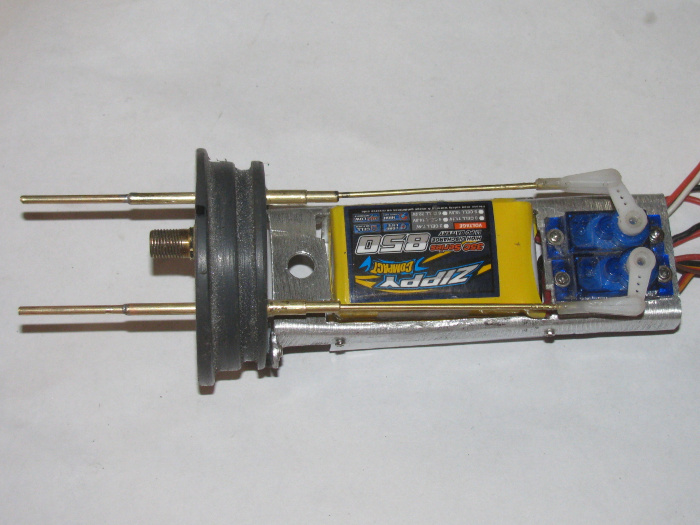

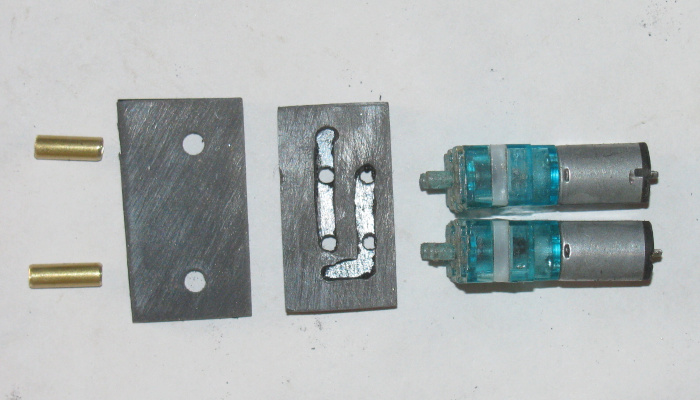

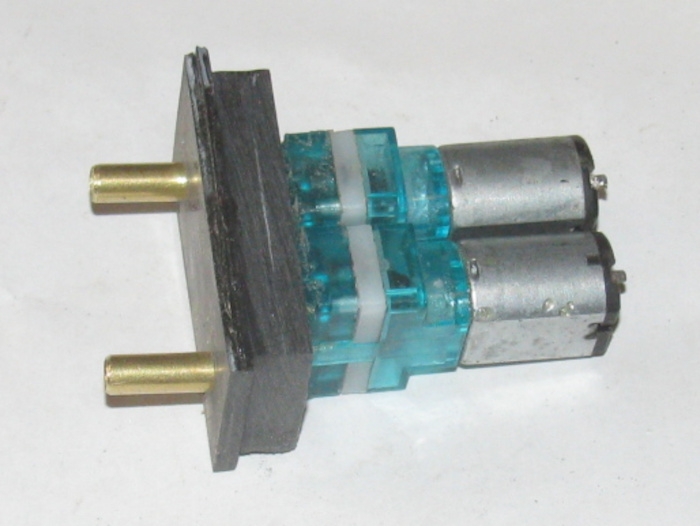

I have cut the plastic pieces to build the 1 to 2 gear assembly that

will go on the rear end cap.

The 2 main frame pieces are made of 2 pieces of sheet plastic bonded

together. (4 pieces altogether)

The re are 2 spaces made from 7 pieces of sheet plastic to get a thickness

so the gears can fit between without binding.

The frames are made.

1 end spacer has cement applied, stacked and placed on 1 of the frames.

The assembly is currently in the vise to apply pressure during the

cement curing.

Later today, I will do the same to the other frame and spacer.

This I can do on my kitchen table.

I will shape the 2 frame pieces to fit together with the 3 gears between

the spacers.

I will cut bushing stock to the gear shafts.

6 all total.

Drilling the assembly after all the glue cures.

I will get a photo of all the parts when I take the first frame with

spacer out of the vise and before I do the second one.